| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Food Waste Pumps |

|---|---|

| Brand Name: | ACCUVON |

| Model Number: | AF 200 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Rotor Type: | Rubber |

| Protection plate: | Wear-resistant steel / Hard steel |

| Flange: | DN 200 mm |

| Flow: | 5.5-340 m³/h |

| rate of flow: | 9.456 l/rev |

| Medium: | Food Waste |

| Self priming: | 8.5 - 9.5 m |

| Drive: | Electric motor |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

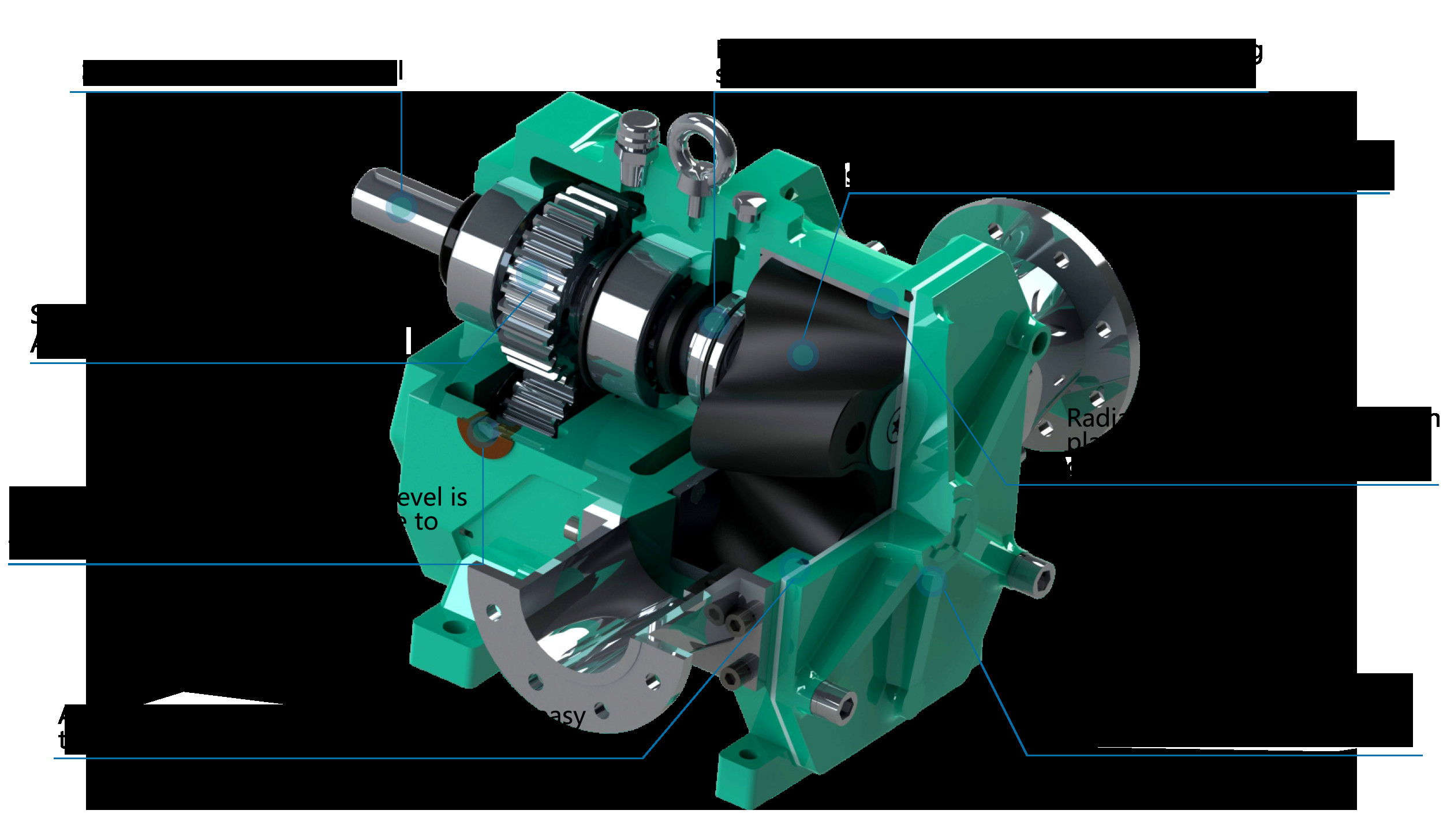

Ease Of Maintenance And Solid Resistant Convey Food Waste Lobe Pump

Accuvon lobe pump

In the food industry, managing waste is an important step to ensuring stable production rates. Pumps play a huge role in managing multiple types of waste, making it essential to choose the best pumps for pumping food and animal waste and byproducts. For food waste, a pump is needed that can reliably pump tough solids and not be prone to clogging which could only lead to downtime and loss of production. Pumping solids is demanding due to the high potential for clogging.

For this situation, Accuvon lobe pump can solve perfectly thanks to they are large and direct inlet opening gives highly viscous media and stiff, clumpy elements direct access to the displacement chamber. The medium flows a short distance through the pump chamber, thus ensuring gentle pumping. With fibrous media or media with a tendency to clump, clogging or coiling is nearly impossible.

Specifications:

| ACCUVON | rate of flow l/rev | flow (m³/h) | pressure (Mpa) | speed rpm | Flange diameter DN mm | power Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Note: Above flange is regular for each model, besides we also offer various flange connection according to your requirements

Design and Materials:

Structure features

The pump cavity design is so simple. All models of pumps retain simple design styles. The fast -opening pump cover is opened to provide guarantee for user maintenance personnel without disassembling the pipeline. The driver can guarantee online repair. Greatly reduced the stop time. Before and after, the upper and lower wear -resistant internal lining design, comprehensively ensure the non -wear of the pump shell and ensure long -term durability. Such a simple maintenance characteristics reduce the operating cost of the entire life cycle of the equipment.

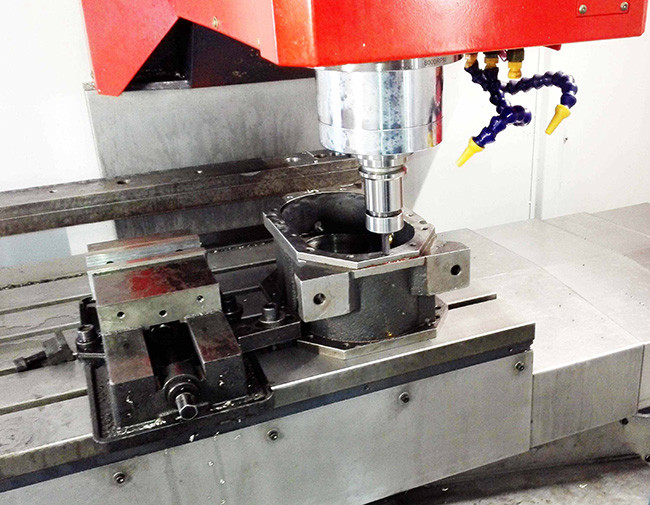

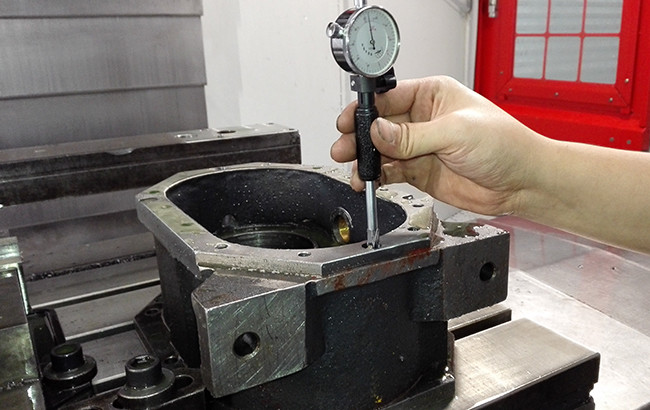

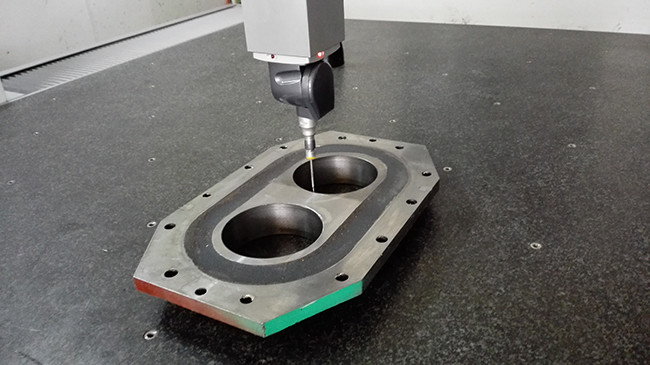

Quality inspection photos

|