| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Food Waste Pumps |

|---|---|

| Brand Name: | accuvon |

| Model Number: | AF 150 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Connection: | DN 200 |

| Rotor material: | Hart metal |

| Flow Range: | 100 m³/h |

| Speed: | 190 rpm |

| Pump casing material: | Grey cast iron |

| Seal Type: | single-acting mechanical seal |

| Pressure: | 2 bar |

| rotation: | Reversible |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

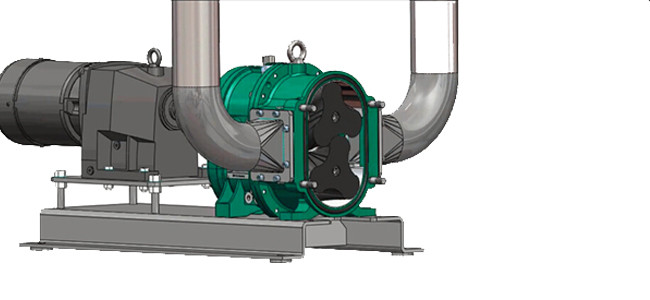

Food Waste Slurry Pump / Anaerobic Digestion / Organic Matter Disposal

Reducing the cost of food waste disposal into landfill is a key performance indicator for manufacturers today. how processing food waste by removing solids and water allows manufacturers and their recycling partners to extract bio fuel. This can then be sold on to gas utilities and municipal councils.

Anaerobic digestion helps alleviate increasingly punitive Landfill Tax. The slurries are notoriously difficult to process, however Accuvon has found solutions for all types of abrasive and sludge-like mixes.

Organic matter

The facility is fed with kerbside collected food waste, food

processing waste, supermarket food waste and brewery waste

including wastefrom its own outlets. The organic matter enters into

a feed inlet at the start of the process where a rotor chopper

breaks down the raw material.

Rotary lobe pumps move the chopped slurry from holding tanks and

through a heat exchanger to raise the temperature prior to

enteringthe main anaerobic digestion facility. As the hot organic

material enters the main facility it is dosed reliably and

accurately by a Rotarylobe pumps with an inorganic pH buffer to

accelerate and maximise thebreakdown of the material.

The large mass of organic material is ‘churned’ by Rotary lobe

pumps in a plant room connected through a series of pipes to

maximise the surface area and further accelerate the process and

obtain the greatest yield of heat and biogas. The heat is recycled

back into the heat exchanger.

Application Data:

| Pump type | Accuvon AF 150 |

| Pumped medium | Organic matter |

| Temperature | 30°C |

| Rated capacity | 100 m³/h |

| Speed | 190 rpm |

| pH-value | neutral |

| Entrance pressure | -0.2 bar |

| Working pressure | up to 2 bar |

Technical Data:

| Casing | Grey cast iron |

| Radial casing liners | Hart metal |

| Casing protection plate | Hart metal |

| Mechanical seal | SIC / SIC |

| O-Rings | FKM |

| Shaft seals | FKM |

| Rotors | dual-lobe, linear, Premium profile, steel |

| Drive | Helical gear motor, 30 kW |

Advantages of this Accuvon AF 150

| 1 | - Free ball channel Ø 75 mm |

| 2 | - Low-wear biogas rotor with Premium profile |

| 3 | - Electronic protection from running dry |

| 4 | - Pumping of abrasive Media |

| 5 | - Resistant to pressure |

| 6 | - Medium unwetted shafts |

| 7 | - Self-priming |

| 8 | - Temperature sensor in the pump casing |

| 9 | - Adjustable speed, depending on entrance pressure via frequency converter |

| 10 | - Ease of maintenance (Maintenance in Place) |

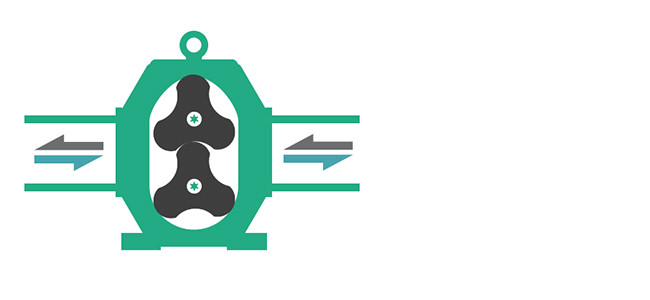

operating principle

• Self-priming, valveless, positive displacement pump

• Designed with two shafts with parallel axes

• The shafts move relatively to one another thanks to external timing gear

• The displacers (=rotors) roll off each other with minimum axial and radial clearance

• In every position, the rotors and casing close the suction chamber against the pressure chamber

• Gentle, low-pulsation pumping

• For viscous, solid, abrasive or shear-sensitive media

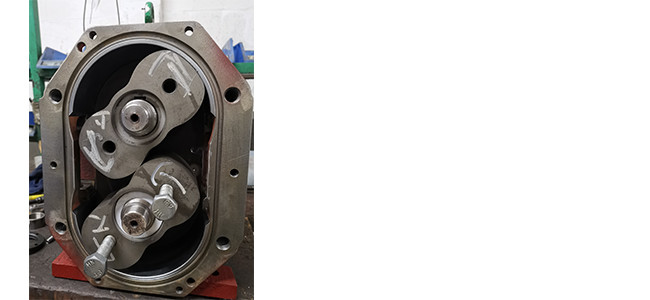

Accuvon's range of rotors –the Premium rotor

Premium profile– of biogas rotors

• Large sealing area

• Effective wiper edge

• Pressure-resistant

• Made of steel, stainless steel or plastic

axial and radial casing protection

To protect the pump casing from abrasive media and solids, we developed replaceable casing protection plates and liners several years ago.

The casing protection is replaced in a few steps, based on the MIP principle.

Easy maintenance– Maintenance in Place

• Reduced maintenance times and downtimes

• Maintenance at installation site by customer's in-house staff

|