| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Lobe Pump |

|---|---|

| Brand Name: | ACCUVON |

| Model Number: | AP 100 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Rotor Type: | Stainless steel rotor |

| Axial and radial casing protection: | Front wear plate, radial liner ,Hard metal |

| Seal: | Single mechanical seal |

| Flow: | 1.1-66 m³/h |

| Self-priming: | 9.5 m |

| Medium: | Food And Beverage |

| Rate of flow: | 1.875 l/rev |

| Pump of material: | Hard metal |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Low Parts Replacement Costs Rotary Lobe Pump In Food And Beverage

Product Description:

Sanitary grade lobe pump is one of the products specially developed by ACCUVON pumps company to meet the customers in the production process of high hygiene requirements. Working chamber has sanitary rotor, rotor locking nut O - ring, pump body without sanitary dead angle and Higher hygienic grade. Support CIP, SIP. The surface roughness is 0.2--0.6mm, in accordance with 3A, FDA standards. Can be widely used food, medicine and other materials with high requirements for hygiene level.

Specifications:

| Description | Rotary Lobe Pumps |

| Rotor | Duplex stainless steel |

| Seal | Double mechanical seal |

| Axial and radial casing protection | High-strength steel , resistant to wear |

| Drive | Variable speed gear motor |

| Material of pump | Full of stainless steel |

| Pressure | 0 - 1.4 Mpa |

| Flow | 1.6 - 66 m³/h |

| Power | 3 - 22 / KW |

| Speed | 10 - 600 rpm |

| Work efficiency | Up to 85% |

| Medium | High-corrosive / high-viscous / sanitary medium |

| Self - priming | Up to 9.5m vertical / 30m horizontal |

| Custom printing | Acceptable |

Parameter of AP 100

| Drive | Weight | Dimensions | |

| KW | KG | L / mm | H / mm |

| 3 | 204 | 1268 | 394 |

| 4 | 216 | 1288 | 419 |

| 5.5 | 237 | 1368 | 454 |

| 7.5 | 250 | 1408 | 454 |

| 11 | 305 | 1498 | 509 |

| 15 | 368 | 1498 | 509 |

Rotor types

Different forms of rotor design meets the diverse needs of users, and the materials of the rotor are also diverse, such as NBR rubber, EPDM rubber, FPM rubber, FFKM rubber, PU, Stainless steel, copper, PTFE, etc.

Advantage

--Capacity up to 1800 m3/h

--Head up to 120 m

--Solids handling up to 95 mm

--Viscosity up to 100000 cp

--Technical features: Wide selection of models (including mobile and ATEX), sizes and materials

--available three type of mechanical seals types

--Casing in block design

--Pump shaft does not become in contact with the pumped liquid

--Wide selection of rotors, which can be adapted to specific parameters (including versions with replaceable lobe tips and special version for biogas industry)

--Self-priming, no vacuum system necessary

--Pump can be used in both horizontal and vertical position

--Easy pump maintenance, no line disassembling necessary

--Replaceable wear plates in casing upper and bottom part (option), as well as in front and rear part (standard)

--Quench chamber between pump casing and gear box Adjustable flow 1:6

--Can pump chemically aggressive and viscous liquids

--Can be reversed

--Capable of running without causing damage

--Can be driven by electric, diesel, hydraulic, pneumatic engine and PTO Compact size

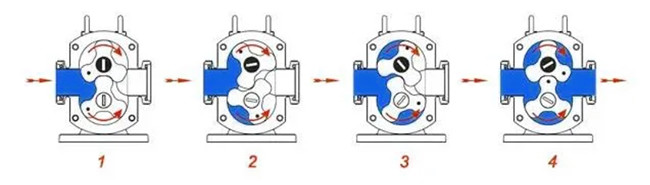

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps we also called them lobe rotor pumps. They are one popular transfer pump to conveying the food, beverage, pulp and paper, chemical, pharmaceutical and so on. The rotor lobe pump relies on two synchronously rotating rotors that generate suction (vacuum) at the inlet during the rotation. Thereby sucking in the material to be conveyed. Both rotors split the rotor chamber into different spaces. Then operate in the order of 1-2-3-4. The medium is delivered to the discharge port. In this cycle, the medium (material) is continuously transported out by the source.

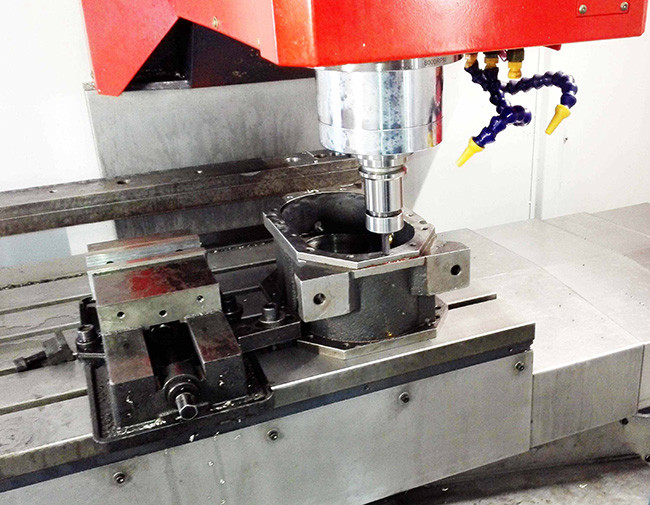

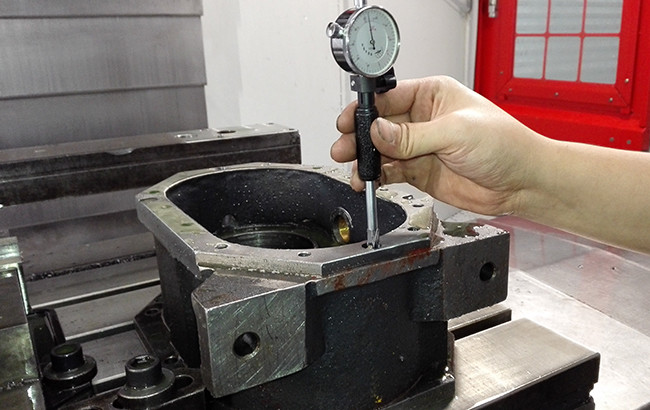

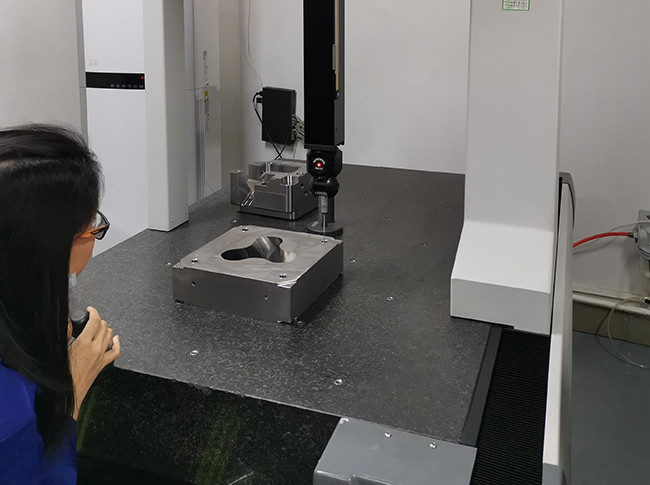

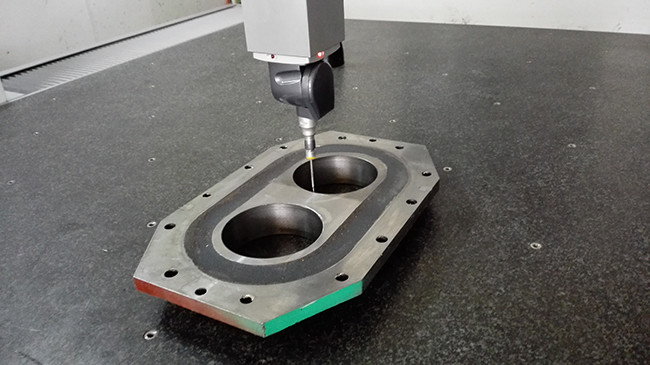

Quality inspection photos

|