| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Lobe Pump |

|---|---|

| Brand Name: | ACCUVON |

| Model Number: | AP140 |

| Certification: | API , IOS , CE, 3A , FDA |

| Place of Origin: | Guangdong , China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000 Pieces per Month |

| Delivery Time: | 8 - 12 work days |

| Packaging Details: | Export wooden box packaging |

| Rotor Type: | SS 316 Tri-lobe rotor |

| Pump material: | SS 304 |

| Seal: | mechanical seal |

| Flow: | 4-246 m³/h |

| Self-priming: | Up to 9.5 m |

| Medium: | Sugar |

| Rate of flow: | 6.828 l/rev |

| Drive: | Electric motor / Hydraulic motor |

| Company Info. |

| Accuvon (Guangzhou) Pumps Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Saving Energy And High Safety SS316 Lobe Pump For Sugar Industry

Brief introduction :

During the processing of starch sugar, there are liquefaction jet,

flash discharge, QC pouring etc. Accuvon lobe pumps have developed

different types of pumps for different processes in the sugar

industry to meet the transportation requirements, such as

high-efficiency negative pressure lobe pump is used for flash

evaporation to ensure the smooth delivery of vacuum and materials,

the low-speed crystallization sugar pump is used for

crystallization sugar delivery, with low shear force and stable

delivery; the heat preservation rotor pump is used for maltose

whose viscosity changes due to temperature changes, and the

delivery is stable , Low noise.

Specifications:

| ACCUVON | rate of flow l/rev | flow (m³/h) | pressure (Mpa) | speed rpm | Flange diameter DN mm | power Kw |

| AC25 | 0.196 | 0.1-7 | 0-1.2 | 10-600 | DN25 | 0.75-5.5 |

| AC50 | 0.392 | 0.2-14 | 0-1.0 | 10-600 | DN50 | 1.1-5.5 |

| AC75 | 0.588 | 0.3-21 | 0-0.6 | 10-600 | DN50 | 1.1-5.5 |

| AP80 | 1.125 | 0.6-400 | 0-1.8 | 10-600 | DN80 | 3-22 |

| AP100 | 1.875 | 1.1-66 | 0-1.4 | 10-600 | DN100 | 3-22 |

| AP120 | 2.864 | 1.7-103 | 0-1.0 | 10-600 | DN100 | 3-22 |

| AP140 | 3.714 | 2.2-133 | 0-0.6 | 10-600 | DN125 | 7.5-22 |

| AF125 | 4.566 | 2.7-164 | 0-1.6 | 10-600 | DN125 | 11-55 |

| AF150 | 6.828 | 4-246 | 0-1.2 | 10-600 | DN150 | 11-55 |

| AF200 | 9.456 | 5.5-340 | 0-0.8 | 10-600 | DN200 | 11-55 |

| AX250 | 12.5 | 7.5-487 | 0-2.5 | 10-650 | DN250 | 22-315 |

| AX300 | 25 | 15-975 | 0-1.0 | 10-650 | DN300 | 30-315 |

| AX350 | 37.5 | 22.5-1463 | 0-0.6 | 10-650 | DN350 | 45-315 |

| AX450 | 50 | 30-1950 | 0-0.4 | 10-650 | DN450 | 55-315 |

| AX350D | 75 | 45-2926 | 0-0.6 | 10-650 | DN350*2 | 90-450 |

| AX450D | 100 | 60-3900 | 0-0.4 | 10-650 | DN450*2 | 110-600 |

Note: Above flange is regular for each model, besides we also offer

various flange connection according to your requirements

Advantages

ACCUVON rotary lobe pumps are designed based on the exploration of

more than 3,000 fluids in various industries. They are particularly

pumping for high viscosity, high solids, sanitary and corrosive

fluids. The pumps are widely used and have long service life

benefits from the below features.

1. Interchangeable rotors, multi connection type and installation

type, fit for various applications.

2. Targeted seal for specific application, ensure a reliable

sealing.

3. Compact structure, easy assembling and disassembling.

4. Maintenance in place , easy cleaning, CIP able and SIP able.

5. Few wearing parts, low maintenance.

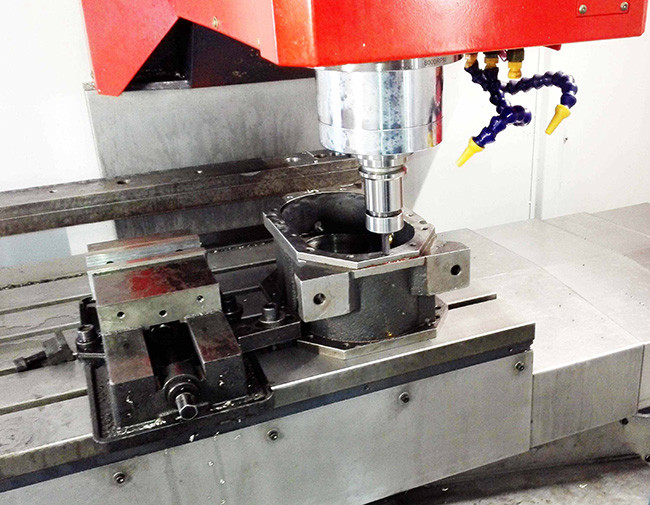

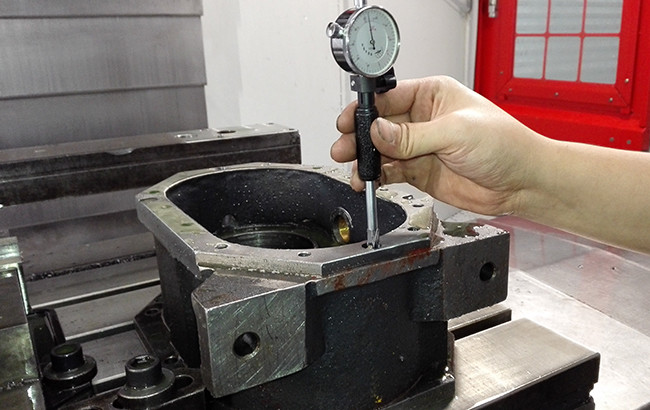

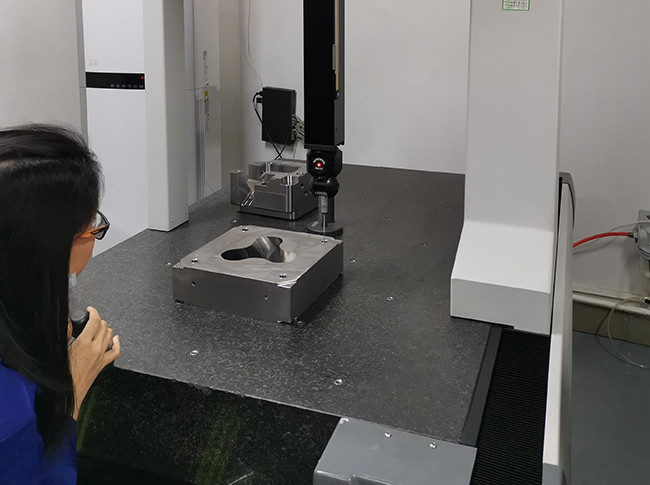

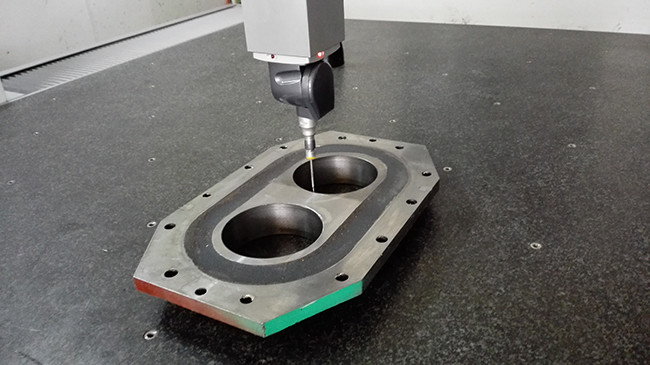

6. All main parts proceed by CNC, high precision fabrication.

7. No contact between the rotors, rotors and pump chamber.

8. Multi bearings with separate arrangement, high pressure

resistance.

9. Axis key synchronous adjustment, no rotor collision problem.

10. The flow can be controlled at will by frequency inverter.

11. Capable to pump the viscous medium from 1cp to 2million cps.

12. Capable of pumping mixture of gas, fluid and solid medium.

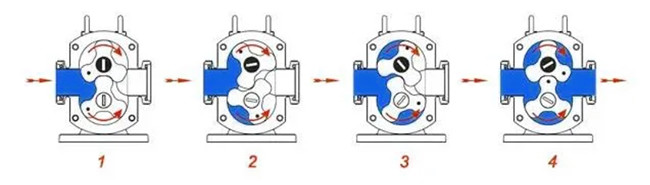

Working Principle of Rotary Lobe Pump:

The rotary lobe pumps we also called them lobe rotor pumps. They are one popular transfer pump to conveying the food, beverage, pulp and paper, chemical, pharmaceutical and so on. The rotor lobe pump relies on two synchronously rotating rotors that generate suction (vacuum) at the inlet during the rotation. Thereby sucking in the material to be conveyed. Both rotors split the rotor chamber into different spaces. Then operate in the order of 1-2-3-4. The medium is delivered to the discharge port. In this cycle, the medium (material) is continuously transported out by the source.

Quality inspection photos

|