| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roof Panel Roll Forming Machine |

|---|---|

| Brand Name: | Saibo |

| Model Number: | Gorrguated and Roofing Panel |

| Certification: | CE/ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 300 sets per year |

| Delivery Time: | 70 working days after received deposit |

| Packaging Details: | Suitable for ocean shipment |

| Product Name: | Double Layer Roll Forming Machine |

| Power: | 11KW+7.5kw |

| Steel thickness: | 0.3-0.8mm |

| Decoiler: | 6T hydraulic decoiler |

| Roll Station: | About 22 stations |

| Roller material: | ASTM1045 chrome plated surface with chrome |

| Shaft diameter: | 76mm |

| Drive system: | By chain |

Double Layer Roll Forming Machine line

1. Specification of the material

| 1 | Suitable Material | PI/ PPGI |

| 2 | Width of the raw material | 914/1220mm |

| 3 | Thickness | 0.3-0.8mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine | Double layer roll forming machine |

| 2 | Machine structure | Wall board structure |

| 3 | Total power | About 18.5kw |

| 4 | Roller stations | Upper layer: 22 stations Down layer: 24 station |

| 5 | Productivity | 0-20m/min |

| 6 | Drive system | By chain |

| 7 | Diameter of shaft | ¢76mm solid shaft |

| 8 | Voltage | 480V 60Hz 3phases (Customized) |

| 9 | Color Of The Machine | Bule and yellow |

| 10 | Deliver time | 60 days |

| 11 | Terms Of Payment | 30%T/T 70% pay before shipment |

3. Profile drawing

Upper later:

Down layer

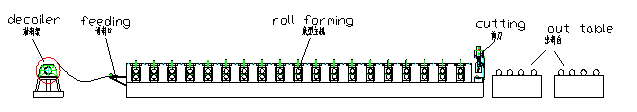

4. The Chart of Process Flow

Hydraulic Decoiler—Roll Forming—Cutting—Out table

5. Machine photos for reference

6. Specification of Components

(1) 5T Hydraulic Un-coiler

(2) Main Roll Forming Machine

(3) Machine Structure

(4) Hydraulic cutting system

(5) Computer Control Cabinet

7. FQA

Q1. What are the main key points for selecting right machines?

|