| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roof Panel Roll Forming Machine |

|---|---|

| Brand Name: | Saibo |

| Model Number: | YX39-320-960 |

| Certification: | CE/ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | T/T or L/C |

| Supply Ability: | 300 sets per year |

| Delivery Time: | 70 working days after received deposit |

| Packaging Details: | Suitable for ocean shipment |

| Product Name: | Kliplock roll forming machine |

| Power: | 7.5KWx2+7.5kw |

| Size Of purlin: | YX39-320-960 |

| Steel thickness: | 0.3-0.8mm |

| Decoiler: | Manual or Hydraulic |

| Station: | About 25 stations |

| Roller material: | Gcr15, chrome plated surface with chrome |

| Machine structure: | Wall board structure |

| Productivity: | 0-15m/min |

Kliplock roll forming machine

1. Specification of the material

| 1 | Suitable Material | PI/ PPGI, 345-550Mpa |

| 2 | Width of the raw material | 1220mm |

| 3 | Thickness | 0.3-0.8mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine | YX39-320-960 |

| 2 | Machine structure | Wall board structure |

| 3 | Total power | Motor power-7.5kw x2 Hydraulic power-7.5kw |

| 4 | Roller stations | About 25 stations |

| 5 | Productivity | 0-15m/min |

| 6 | Drive system | By chain |

| 7 | Diameter of shaft | ¢70mm solid shaft |

| 8 | Voltage | 380V 50Hz 3phases (Customized) |

| 9 | Color Of The Machine | Bule and yellow |

| 10 | Deliver time | 70 days |

| 11 | Terms Of Payment | 30%T/T 70% pay before shipment |

3. Profile drawing

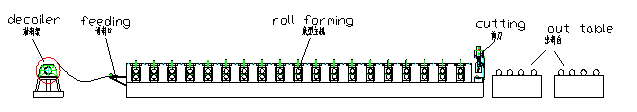

4. The Chart of Process Flow

Manual Decoiler—Roll Forming—Cutting—Out table

5. Specification of Components

(1) Un-coiler

Option1: 5T Manual de-coiler

Option1: 5T Hydraulic de-coiler

(2) Main Roll Forming Machine

(3) Machine Structure

(4) Hydraulic cutting system

(5) Computer Control Cabinet

6. Product Application

This type of roof sheet has advantage inclouding beautiful,

classical appearance and grace taste.

It can be widely used in village, hotel, exhibition, vocation

vallage, family construction and outdoor decorate.

|