| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Glazed Tile Roll Forming Machine |

|---|---|

| Brand Name: | JCX |

| Model Number: | Step tile machine |

| Certification: | CE ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD11000-USD13500 PER SET |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 50 SETS PER MONTH |

| Delivery Time: | 20-30 working days |

| Packaging Details: | Sea worthy standard package: covered with plastic film, fixed into 20/40'gp container |

| Shaft material: | 45# Steel Outer Diameter: 80mm |

| Cutting blade material: | Cr12 Frequency Quenching |

| Number Of Rollers: | 19 stations |

| Raw Material Thickness: | 0.3-0.8mm |

| Usage: | Roof |

| Machine type: | Roll forming |

| Control box language: | As your requirement |

| Export port: | Tianjin |

| PLC brand: | Delta |

| Machine frame: | 350H Steel |

| Company Info. |

| Botou Golden Integrity Roll Forming Machine Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

High Speed Color Steel Glazed Tile Roll Forming Machine For Construction Material Roof Sheets

1. Description of glazed tile roll forming machine:

Glazed tile roll forming machine has many types which can used together with corrugated sheet and IBR sheet, or glazed tile sheet.The roofing sheet is widely used in many kinds of industrial factory, civilian buildings, and Roof board for attached part product. It has own advantage- beautiful appearance, durable using and so on.

Metal glazed tile roll forming machine adopts advanced automatic control software, roof panel roll forming machine realizes production information management, and the whole machine automatic control system adopts a highly integrated network, which makes the automation system more superior.

Our factory is manufacturing high quality guardrail roll forming machines, and regularly exported to Australia, USA, Thailand, Canada,Turkey, Indonesia, Philippines, Malaysia, India, Angola, etc.

2. Technical details of glazed tilel roll forming machine:

| Machine Specifications | |

| Weight | About 6tons |

| Size | About 1.5m*1.5m*1.3m |

| Machine Color | Main color: blue or as your requirement |

| Warning color: your requirement | |

| Suitable Raw Material | |

| Material | Galvanized Steel Coils |

| Thickness | 0.3-0.8mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 18 |

| Diameter of forming rollers shafts | 80mm |

| Roll Forming Speed | 3-5m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

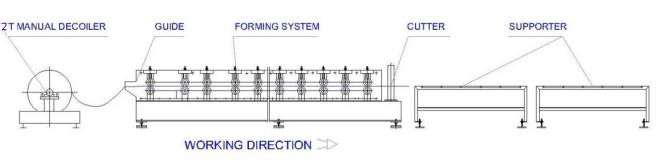

3. Main components of roof panel roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

6. Application

This machine is widely used in the production of the roof wall steel construction and so on.

7. Product photo

8. FAQ

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing

machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business

days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control,

including the laying of raw materials, processing rolls and other

parts, processing, assembly, testing and packaging on the roll

surface and shaft.

Q. Why are your prices higher than others?

A: Because we insist that every factory should put quality first, we make the machines more automated, more reliable and accurate, and have a longer service life. The equipment can be used for nearly 20 years, and we provide lifetime after-sales service.

Q. What is your payment terms?

A:1 : We accept 30% T/T as deposit and 70% T/T as balance before

shipping.

2 : We accept 100% L/C at sight

3: We accept Western Union payments.

4 : Other payment terms you want to pay, please let me know and i

will check and reply you.

|