| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Glazed Tile Roll Forming Machine |

|---|---|

| Brand Name: | JCX |

| Model Number: | step tile forming machine |

| Certification: | CE ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD11000-USD15500 PER SET |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 30 SETS PER MONTH |

| Delivery Time: | 20-30 working days |

| Packaging Details: | Sea worthy standard package: covered with plastic film, fixed into 20/40'gp container |

| Name: | glazed rolling former machine |

| Dimension: | 1.8m*1.3m*1.1m |

| The machine Speed: | 3-5m/min |

| After-sales: | Lifetime |

| Warranty time: | 12 month |

| raw material: | PPGI,PPGL,GL,GI,steel |

| feeding width: | 914mm-1450mm |

| Thickness: | 0.3mm-0.8mm |

| Company Info. |

| Botou Golden Integrity Roll Forming Machine Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Color Steel Metal Glazed Tile Cold Roll Forming Machine For Glazed Roof Panel

1. Description of glazed tile roll forming machine:

We can design the glazed tile profile as your request.

Our factory is manufacturing high quality guardrail roll forming machines, and regularly exported to United States, Canada, Mexico, Colombia, South Africa, Chile, Peru, Zambia, Indonesia, Philippines, Thailand, etc.

Glazed tile roll forming machine popular sell in many countries,

Coil width before rolling is 1000mm / 1200mm /1220mm / 1250mm.

Material common is PPGI material, material thickness common between

0.3-0.8 mm. The finished products are used as the roof and walls of

gymnasiums, airports, theatres, factories, warehouses, garages,

exhibition centers etc.

2. Technical details of glazed tilel roll forming machine:

| Glazed tile Machine Specifications | |

| machine Weight | About 5tons |

| machine Size | About 1.5m*1.5m*1.3m(length x width x height) |

| machine Color | Main color: blue or as your requirement |

| Warning color: your requirement | |

| Suitable Raw Material | |

| Raw Material | Galvanized Steel Coils |

| Raw Thickness | 0.3-0.8mm |

| Yield Strength | 235Mpa |

| Main Technical Parameters | |

| Quantity of forming rollers stations | 20 |

| Diameter of forming rollers shafts | 70mm |

| Roll Forming Speed | 3-5m/min |

| Forming rollers material | No.45 steel, coated with chromed treatment |

| Cutter material | CR12 mould steel, with quenched treatment |

| Controlling system | PLC and Converter |

| Electric Power requirement | Main motor power: 5kw |

| Hydraulic unit motor power: 4kw | |

| Electric voltage | According to customer’s requirement |

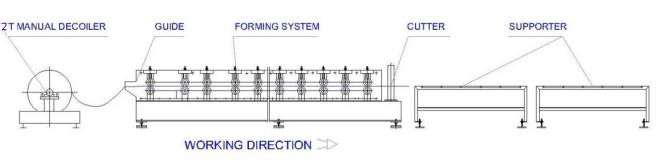

3. Main components of glazed tile roll forming machine

| Decoiler | 1 Set |

| Guiding Equipment | 1 Set |

| Roll Forming Unit | 1 Set |

| Post Cutting Unit | 1 Set |

| Hydraulic Station | 1 Set |

| PLC Control System | 1 Set |

| Reveiving Table | 1 Set |

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

6. Application

This machine is widely used in the production of the roof wall steel construction and so on.

7. Product photo

8. FAQ

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business

days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control,

including the laying of raw materials, processing rolls and other

parts, processing, assembly, testing and packaging on the roll

surface and shaft.

Q1. How do I choose the right machine for me?

1. A machine doesn't just provide a few photos to prove what they can produce 2. A machine should have a complete production and assembly system photos and videos. When choosing a company with a factory, it is necessary to ensure that the company has a complete after-sales service system.

|