| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roofing Forming Machine |

|---|---|

| Brand Name: | DLY |

| Model Number: | paneling machine |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 30sets/month |

| Delivery Time: | 40 days |

| Packaging Details: | naked or wooden |

| name: | Roofing Forming Machine |

| Voltage: | 380V Or As Customize |

| Tile type: | Colored Steel |

| Roller material: | hard chromed,Cr12 |

| Color: | Client's Request,according to the model |

| Power(w): | 5.5KW |

| Raw material: | PPGI / Galvanized Sheet |

| Shaft material: | Carbon steel 45# |

| Company Info. |

| DLY Metal Roofing Machine |

| View Contact Details |

| Product List |

TR37 Trapezoidal Roofing Forming Machine 380V Metal Roll Former

1. Description of Roofing Forming Machine

2. Specifications of Roofing Forming Machine

| Suitable material | PPGI or galvanized coil |

| Suitable material | Raw material width:1000 and 1250mm thickness 0.3-0.8mm |

| Productivity | 12-15m/min |

| Roller material | 45# after heating treatment and with chromium |

| Spacer, balance bar, screw | All do chromium to ensure beautiful appearance |

| Diameter of active shaft | Φ75mm |

| Main machine structure | 400H |

| Wall plate | 20mm |

| Power | 3KW main motor,cycloidal reducer work stable and no noise |

| Shear | Hydraulic shear, blade material CR12 |

| Transmission | 1’’ gear chain |

| Control system | Delta PLC computer control system with Chrizi inverter to ensure precision; Winwen color touch screen. Program is made by English, working mode: automatic and manual |

| Hydraulic system | 3kw hydraulic motor |

| Voltage | AC380V/50HZ/3 phase or AC220-240V/60HZ/3 phase or AC220-240V/60HZ/single phase |

| Upgrade manual decoiler | Max loading weight:5000kgs,Inner Diameter:508-610mm,max coil width:1250mm |

| Set off table | one pcs, 6 step roller, each is 3000mm long |

| Size(length*width*height) | 9000*1500*2500MM |

| Weight | 7500kgs |

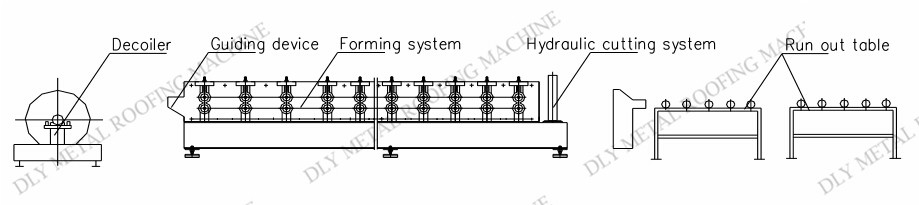

| Component | Upgrade manual decoiler-guide feeding-forming part-shear blade device--hydraulic system-PLC computer control cabinet-set off table |

4. Production Flow of Roofing Forming Machine

Manual decoiler→Feeding material into machine→Roll forming

machine→Measure length→Hydraulic cutting→Finished Products

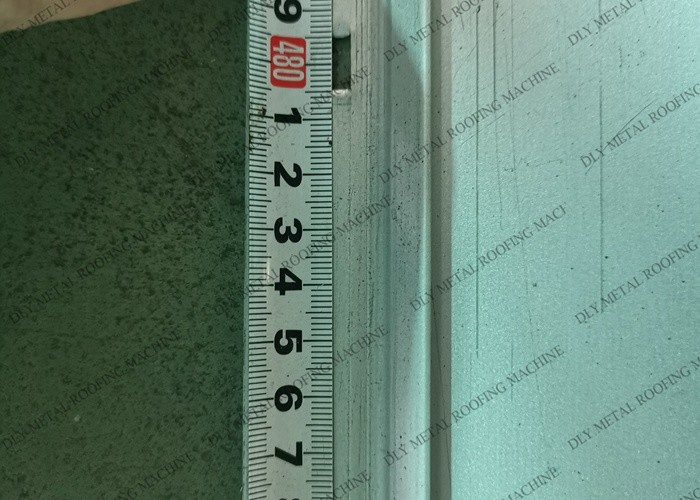

5. Details of Our Roofing Forming Machine

|