| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Turnkey PCB Assembly |

|---|---|

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 100000pc/Month |

| Delivery Time: | 4 Weeks |

| Packaging Details: | PCB + Box |

| Brand Name: | CUSTOM MADE |

| Certification: | ISO/UL |

| Keyword: | Turnkey PCB Assembly |

| Applications: | Automotive Electronics, Communications |

| Materials: | High-Tg FR4, RCC, FR4 |

| Service: | Fast turnkey PCB assembly |

| PCB boards: | Rigid-Flex Board, Metal Substrate Boards |

| Number of layers: | 2-64 |

| Surface Finished: | Immersion Gold+OSP |

| Copper Thickness: | 0.3-12 oz |

| Payment Method: | T/T |

| Whether to Support customization: | Support |

| Logistics: | Accept customer specified logistics |

| Company Info. |

| TONGZHAN INDUSTRIAL LIMITED |

| View Contact Details |

| Product List |

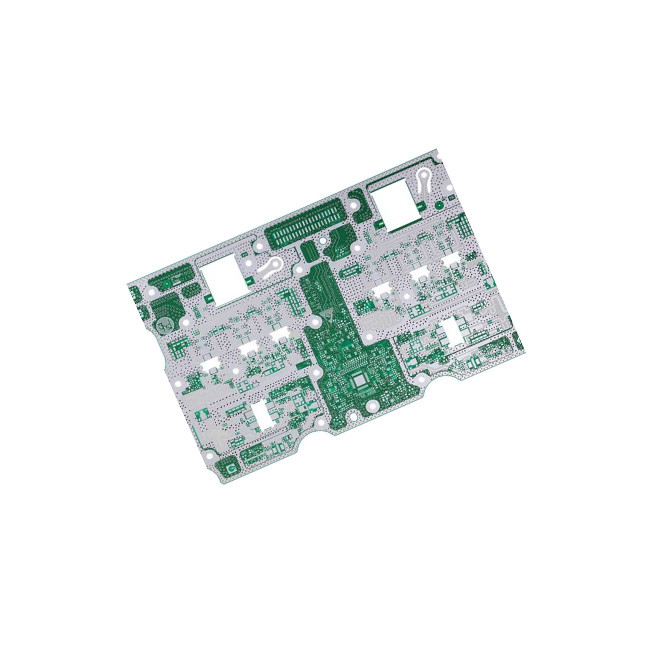

SMT Turnkey PCB Assembly Electronical Products Immersion Gold + OSP

Turnkey PCB Assembly Description:

1. Quick-turn and flexible delivery

2. Support a wide range of PCBs: high-layer, multi-layer,

rigid-flex, high frequency, high speed, etc.

3. Professional supplier positioning.

4. Seamless link from prototype to mass production.

5. Whole-flow quality assurance, IPC, Special industry inspection

standard.

Turnkey PCB Assembly Parameters:

Item | Technical Parameter |

Layer | 2-64 |

Thickness | 0.3-6.5mm |

Copper Thickness | 0.3-12 oz |

Min Mechanical Hole | 0.1mm |

Min Laser Hole | 0.075mm |

HDI | 1+n+1,2+n+2,3+n+3 |

Max Aspect Ratio | 20:01 |

Max Board Size | 650mm*1130mm |

Min Width/Space | 2.4/2.4mil |

Min Outline Tolerance | ±0.1mm |

Impedance Tolerance | ±5% |

Min PP Thickness | 0.06mm |

Bow &Twist | ≤0.5% |

Materials | FR4, High-Tg FR4, Rogers, Nelco, RCC, PTFE, M4, M6, TU862, TU872 |

Surface Finished | HASL, HASL Pb Free Immersion Gold/Tin/Silver Osp, Immersion Gold+OSP |

Special Capability | Gold Finger Plating, Peelable, Carbon ink |

Turnkey PCB Assembly Introduction:

1. Provide mechanical support for fixing and assembling various

electronic components such as integrated circuits, realize wiring,

and electrical connection or electrical insulation between various

electronic components such as integrated circuits, and provide

required electrical characteristics.

2. Provide solder mask graphics for automatic welding, and provide

identification characters and graphics for component insertion,

inspection, and maintenance.

3. After the electronic equipment adopts printed boards, due to the

consistency of similar printed boards, manual wiring errors are

avoided, and automatic insertion or mounting of electronic

components, automatic soldering, and automatic detection can be

realized, which ensures electronic products. quality, improve labor

productivity, reduce costs, and facilitate maintenance.

|