| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

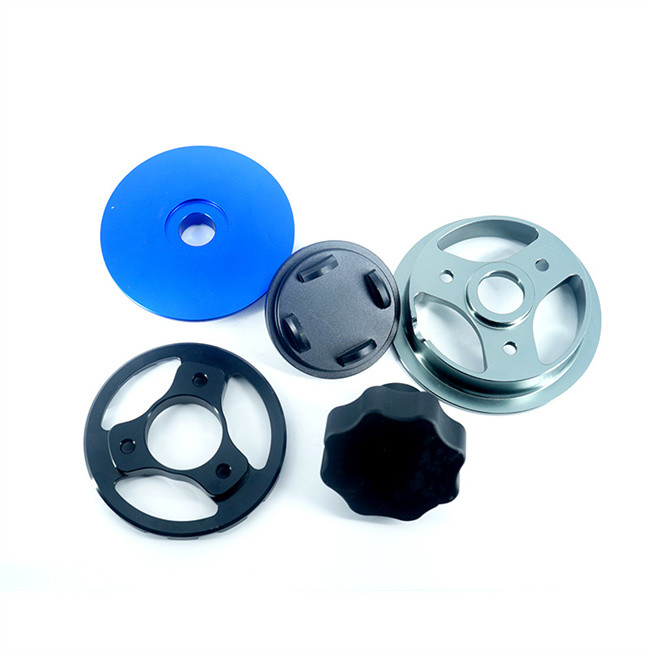

| Categories | CNC Lathe Turning Parts |

|---|---|

| Brand Name: | Custom |

| Model Number: | XSZ35621 |

| Place of Origin: | shenzhen |

| MOQ: | 5pcs |

| Price: | 1-15usd |

| Payment Terms: | T/T, Western Union/paypal |

| Supply Ability: | 60000pcs/year |

| Delivery Time: | 9-12days |

| Packaging Details: | Prevent from damage |

| Type: | Turning,Milling |

| Material capabilities: | Aluminum,Copper,Steel Alloys |

| Surface treatment: | anodizing,brush,polish,Polishing,Heat Treatment |

| Process: | Turning,Cnc Turning/milling/lathe process |

| Service: | OEM ODM |

| Color: | Any color |

| Tolerance: | 0.01-0.05mm or Customized |

| Company Info. |

| Xinshizhan Precision Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product pictures:

Xinshizhan Precision co., LTD, mainly do precision hardware processing, non-standard parts machining, and machinery parts. We are dedicated in manufacturing of custom products for OEM market.

| |||||||||||||||||||||||

What are our Advantages over others?

a).We are the Manufacture,not a trading company, less cost purchase, competitive price.

b).More than 10 years' Machining Experience.

f).During our cooperation: We have QC depart,Sales Depart,Engineer Depart,Shipping Depart,After-Sales,Depart,to serve you all the time.

Factory details and display

| Equipment List | Brand | Model | Working Track | Tolerance(mm) | Quantity(Set) |

| CNC Machines | FS (TW) | KMC-L850 | 800*500*500 | & plusmn;0.01 | 6 |

| FANUC | a-D14MIA | 500*400*330 | & plusmn;0.001 | 10 | |

| BROTHER | TC-S2DZ | 500*400*300 | & plusmn;0.001 | 12 | |

| Taikan (TW) | 500*400*300 | & plusmn;0.001 | 15 | ||

| BROTHER | TC-31A(Double Table) | 300*250*350 | & plusmn;0.002 | 5 | |

| FS (TW) | 4 Axis CNC | 500*400*300 | & plusmn;0.001 | 5 | |

| TSUGAMI | CNC lathe Center | 530*1500 | & plusmn;0.001 | 15 | |

| Mazak(5-Axis) | I-600 | 510*910*510*360°*(-120°-30°) | & plusmn;0.001 | 2 | |

| TSUGAMI | CNC Milling and Turning Machine | 530*1500 | & plusmn;0.001 | 5 | |

| WEDM-HS | Tianlong | DK7728 | 230*280*400 | & plusmn;0.02 | 8 |

| Laser Engraving Machine | Aprime | CJ-CO2-10 | 250*250 | ±0.001 | 1 |

| Drilling Machine | West Lake | Manual | 15 | ±0.01 | 5 |

| Tapping Machine | West Lake | Manual | 25 | ±0.01 | 5 |

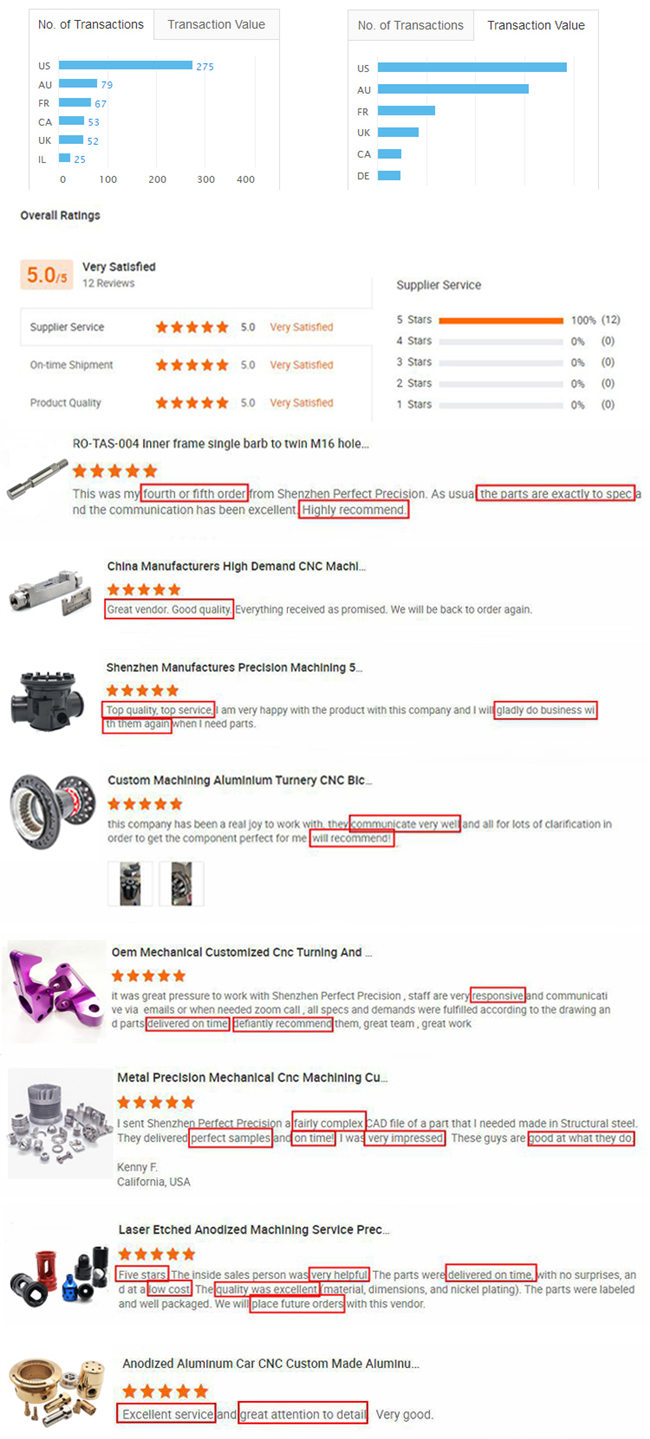

Customer Feedback

FAQ:

1.Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China.

2. How can I get a quote?

Detailed drawings (PDF/STEP/IGS/DWG...) with material, quantity and

surface treatment information.

3. Can I get a quote without drawings?

Sure, we appreciate to receive your samples, pictures or drafts

with detailed dimensions for accurate quotation.

4. Will my drawings be divulged if you benefit?

No, we pay much attention to protect our customers’ privacy of

drawings, signing NDA is also accepted if need.

5. Can you provide samples before mass production?

Sure, sample fee is needed, will be returned when mass production

if possible.

6. How about the lead time?

Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

7. How do you control the quality?

(1) Material inspection--Check the material surface and roughly

dimension.

(2) Production first inspection--To ensure the critical dimension

in mass production.

(3) Sampling inspection--Check the quality before sending to the

warehouse.

(4) Pre-shipment inspection--100% inspected by QC assistants before

shipment.

8. What will you do if we receive poor quality parts?

Please kindly send us the pictures, our engineers will find the

solutions and remake them for you asap.

|