| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | 5 Axis CNC Parts |

|---|---|

| Brand Name: | YMP |

| Model Number: | YMP |

| Place of Origin: | Shenzhen, China |

| MOQ: | 100 |

| Price: | $0.556-1.031 piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 pieces per day |

| Delivery Time: | 7 days |

| Packaging Details: | Inner pearl button, outside carton box, or customized |

| CNC Machining or Not: | CNC Machining |

| Type: | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material Capabilities: | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless Steel, Steel Alloys |

| Micro Machining or Not: | Not Micro Machining |

| Product name: | Custom 4 Axis 5 Axis High Precision CNC Machining Aluminum Parts |

| Material: | Stainless Steel, Carbon Steel, Aluminum, Alloy, Brass, Cooper |

| Finish: | Plating, Paint, Polishing |

| Machining: | CNC |

| Technology: | Precision Machining |

| Standard: | ASTM & AISI & DIN |

| OEM: | Available |

| Keyword: | CNC Machining Parts |

| Dimensions: | Customized |

| Application: | Industrial |

Export Sales Team with many years of experience in handling exports to the US, Europe, Japan, and other countries and regions.

Just give us your sample, drawing, or ideas, and our professional sales team and engineer team, and our workshop staff can make the actual product you want.

Yixin Precision Metal and Plastic Co., Ltd is one of the professional manufacturers of various kinds of OEM/ODM precision casting parts, stainless steel rigging hardware, and stainless steel marine hardware always regards quality as a key criterion, and applied to all aspects of its operations. With a group of highly professional and experienced engineers taking charge of the design, drawing draft & modification, production, and quality control, we are able to meet all of our customer's requirements.

T/T, L/C, Western Union, PayPal, Trade Assurance etc...

Normally our delivery time is 30-35 days. It also should depend on what kind of product and the quantity you require. But if we have the products in stock, then the delivery time will be in about 10 days or less.

Yes, of course. Free samples are available.

Yes, any customized product is available. You can directly send us your design product draft, then we will discuss it with our professional designers and confirm all the right information for you.

Yes. We offer the service of adding customers' logos to the products. There are many types of this service.

If you have this need, welcome to contact me!

Yes, we are. We have our own factory and showroom. Warmly welcome to visit our factory at any time. We can also pick you up at the airport and station.

Yes. For big orders and Frequent Customers, we give reasonable discounts.

We’re 100% responsible for damage of full container goods if it’s caused by our improper package.

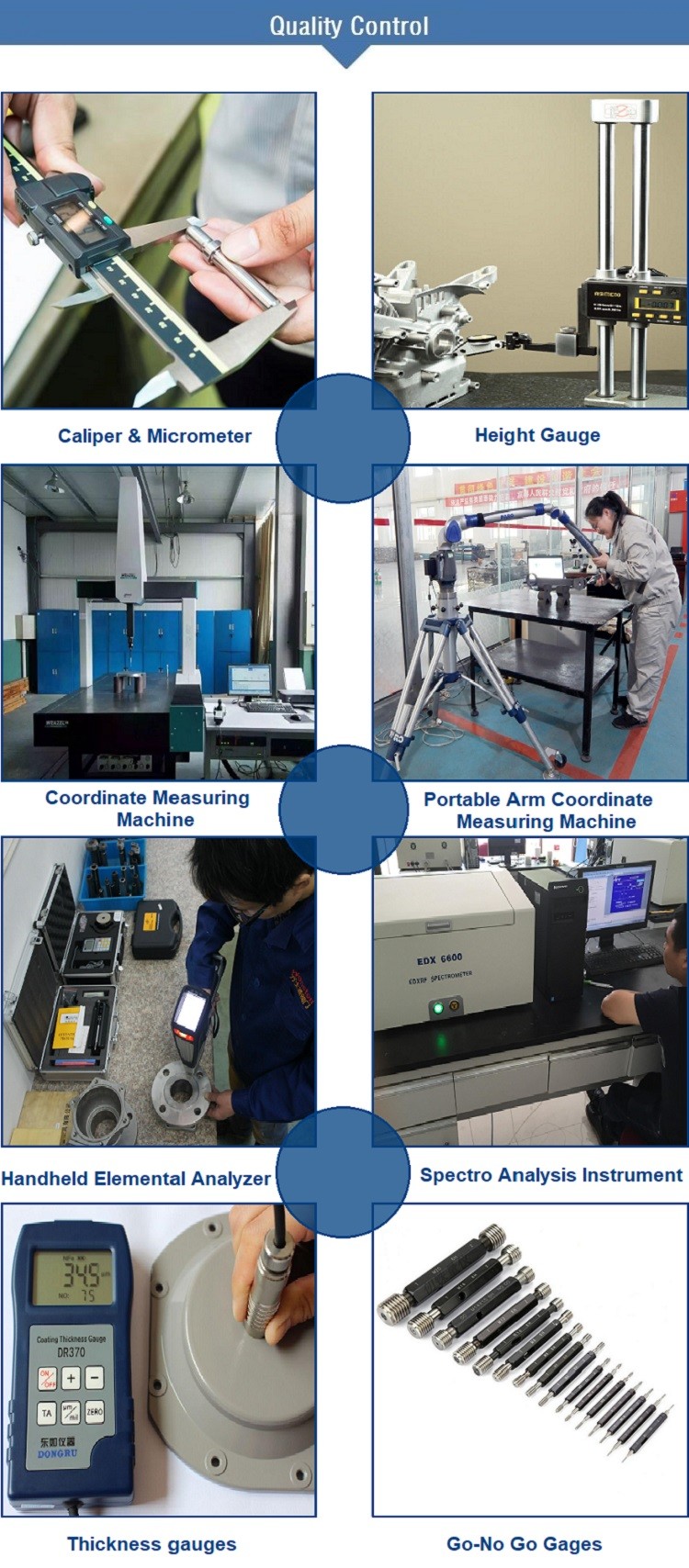

We have very strict QC team to control the quality problem.

From material to finished products, each step, our inspection man to inspect it.

For each order, we will test and have the record.

Investment cast (wax mould made by middle-temperature wax) /Precision casting, lost Wax Casting (wax mould made by low-temperature wax)/ Precision casting.

CT7-8 for the Lost-wax casting Process, CT4-6 for the investment casting process.

CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming /Grinding/Honing and etc

From 0.005mm-0.01mm-0.1mm.

Metal Parts Solution for Vehicle, Agriculture machine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts etc

| Item name | Precision Machining |

| Tolerance | minimum tolerance 0.0005mm |

| Material | Stainless Steel: SS201,SS301,SS303, SS304, SS316, SS416 etc. |

| Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |

| Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |

| Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |

| Copper: C11000,C12000,C12000, C36000 etc. | |

| Plastic: ABS, PC, PE, POM, Delrin, Nylon, PP, Peek etc. | |

| Other: Titanium, etc. We handle many other type of materials. Please contact us if your required material is not listed above. | |

| Surface Treatment | Stainless Steel:Polishing, Passivating, Sandblasting, Laser engraving,Oxide black, Electrophoresis black |

| Steel: Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, Heat treatment. | |

| Aluminum:Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing. | |

| Brass: Nickel plating, chrome plating, Electrophoresis black, Oxide black, Powder coated. | |

| Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser engraving. | |

| Drawing Format | jpg/. pdf/. dxf/. dwg/. igs./.stp/x_t. etc |

| Testing Machine | CMM, Digital Height Gauge, caliper, Coordinate measuring machine, projecter machine, roughness tester, hardness tester and so on |

| Certificate | CE, TUV, SGS or as your requirement to do test by the third party |

| Delivery time | 10-15 days for sample, 35-40 days for bulk order |

| Packing | Plywood pallet, plywood box or as per your requirement |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC, FQC, QA |

| Service | Warm and quick response service provided by the professional Export Sales Team with many years' experience in handling exports to the US, Europe, Japan and other countries and regions. |

Which parts are suitable for precision machining?

In our parts processing industry, we may all know that precision machining requires high precision. The main characteristics of precision machining are high manufacturing precision and accurate tool setting, and it can process some high-precision parts.

fine sandblasting parts

fine sandblasting parts knurling parts

knurling parts CNC engraving parts

CNC engraving parts powder coating parts

powder coating parts CNC machining parts

CNC machining parts bending parts

bending parts 4-axis CNC machining parts

4-axis CNC machining parts anodize finished parts

anodize finished partsMost CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

|