| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Pellet Mill Die |

|---|---|

| Brand Name: | APEX BIOMASS |

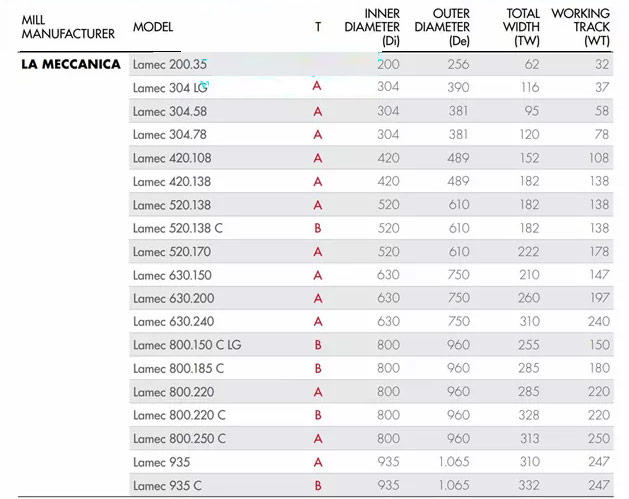

| Model Number: | LA MECCANICA |

| Certification: | CE SGS |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100pcs |

| Delivery Time: | 15 working times |

| Packaging Details: | Plywood case with film ,for sea transportation |

| Items: | Pellet Machine Ring Die |

| Name: | Lamec 800.250 SS Steel Feed Pellet Die Manufacture 2.0mm |

| Raw material: | Top stainless steel X46Cr13 |

| Pellet die hole size: | 1.0-6.0mm /6mm-12mm as demands |

| Pellet Machine brand: | LA MECCANICA |

| Inner size: | 800mm |

| Lifetimes: | 2000h as raw material |

| Size: | as drawing |

| Company Info. |

| LIYANG APEX BIOMASS EQUIPMENT CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Lamec 800.250 SS Steel Feed Pellet Die Manufacture 2.0mm

1 For Awalia pellet mill: Awalia 420, Awalia350, etc

2. For Buhler pellet mill: Buhler350, Buhler400, Buhler420, Buhler520, Buhler660, etc.

3. For CPM pellet mill: CPM2016, CPM3016, CPM3020, CPM3022, CPM7726, CPM7932, etc.

4. For CPP pellet mill: CPP150, CPP200,CPP360,CPP300,CSP020, etc.

5. For IDAH pellet mill: IDAH530, IDAH530F, IDAH635D, etc.

6. For Muyang pellet mill: MUZL180, MUZL350, MUZL420, MUZL600,

MUZL1200, MUZL610, MUZL1210, MUZL1610, MUZL2010; MUZL350X,

MUZL420X, MUZL600X, MUZL1200X(Especially for shrimp feed pellet,

diameter: 1.2-2.5mm)

Muyang FAMSUN350,Muyang FAMSUN420, Muyang FAMSUN550, Muyang

FAMSUN600, Muyang FAMSUN1210

7. For Zhengchang feed pellet mill: SZLH250, SZLH300,SZLH320,SZLH350,SZLH400,SZLH420,SZLH508, SZLH678, SZLH768, etc.

8. For HKJ feed pellet mill: HKJ250, HKJ320,HKJ350,HKJ400,HKJ420,HKJ508 etc.

9. For SZLJ feed pellet mill: SZLJ250,

SZLJ320,SZLJ350,SZLJ400,SZLJ420,SZLJ508 etc.

10. For OGM pellet mill: OGM-0.8, OGM-1.5, OGM-6, etc.

11. For VAN ARSEN pellet mill: Van Arson C600, Van Arsen750, Van

ArsenC900, etc.

12. For KAHL pellet mill (Flat die): KAHL38-780, KAHL37-850,

KAHL45-1250, etc.

13. For PTN pellet mill: PTN580, PTN580-C, etc.

14. For Yemmak pellet mill: YEMMAK520, YEMMAK420, etc.

15. For Zhengchang wood pellet mill: MZLH250 ,MZLH320, MZLH350, MZLH400, MZLH420, MZLH508, MZLH678, MZLH768, etc.

16. For Yulong wood pellet mill: XGJ560, XGJ850, etc.

Why us ?

1. Both alloy steel and stainless steel ring die are all drilled by auto gun-drilling machines, so holes will be more smoothly. The max thickness ring die our machines can drill is 140mm(Germany deepth hole auto-drilling machines), and the minimum holes our machines can drill is 1.0mm.

2. Ring die raw material come from China No.1 steel forging factory, the using life can be enhanced about 10%-15%.

3. Advanced holes' designing, ensure the pellets can be made out smoothly, and special holes (row) arrangement, ensure the capacity can be enhanced 10% without broken.

For Pellet die manufacture ,we have own auto gun-drilling machines (12 sets), auto counter-sinking machines, auto lathing machines, vacuum heat treatment machines.

A good pellet mill die can improve product quality and output, reduce energy consumption (granulation energy consumption accounts for 30%-35% of the total energy consumption of the entire workshop), and reduce production costs (the cost of pellet mill die loss accounts for 25%-30% of the maintenance cost of the entire production workshop).Pellet dies must resist abrasion, corrosion from chemical exposure and breakage caused by the physical stresses of pellet formation. The optimum die combines high resistance to abrasion, breakage and corrosion with maximum productivity.

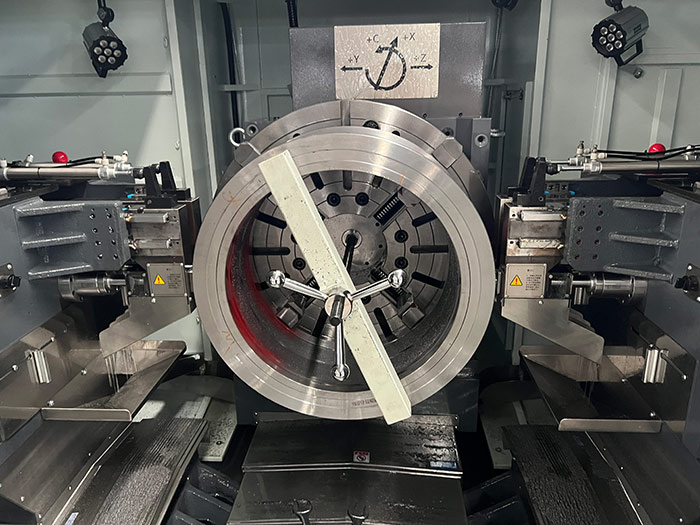

Lamec 800 250 Pellet Machine Ring Die

6mm pellet press die set

Highlight:

The Pellet die raw material :

1. Stainless steel: Chinese Standard: X4Cr13, Germany Standard: X46Cr13.

2. Alloy steel :20CrMnTi

3. Diameter of ring die can do: 1.0mm up to 28mm.

4. Pellet die type can do: Ring Die or Flat Die

The difference between different raw materials :

Customized pellet mill die accept .

Pellet mill die processing :

gun-drilling machine+ auto counter-sinking machine+vacuum heat treatment machine..

WARM TIPS:

1.The rollers should be correctly adjusted, make sure the hole

inlets are not damaged by contact with the rollers or as a result

of tramp metal;

2.Material should be evenly distributed across the whole working

area;

3.Make sure that all holes work uniformly, opening the clogged

holes if necessary;

4.When changing dies, carefully inspect the condition of the die

seating surfaces and fixing systems including collar, clamp or wear

ring.

How to choose the compression ratio :

| Item | Hole Diameter(mm) | Compression Ratio |

| Ring die for animal feed pellet machine | ||

| Poultry&livestock feed | 2.5 - 4 | 1:4-1:11 |

| Fish feed | 2.0 - 2.5 | 1:12-1:14 |

| Shrimp feed | 0.4 - 1.8 | 1:18-1:25 |

| Ring die for biomass pellet machine | 6.0 - 8.0 | 1:4.5-1:8 |

|