| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Floor Deck Roll Forming Machine |

|---|---|

| Brand Name: | DLY |

| Model Number: | metal decking machine |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 30sets/month |

| Delivery Time: | 40 days |

| Packaging Details: | naked or wooden |

| name: | Floor Deck Roll Forming Machine |

| Voltage: | 3 phase and 50 Hz or at buyer's request |

| Product name: | metal roofing machine corrugated floor deck roll forming machine |

| Weight: | about 13 Tons |

| After-sales service provided: | Online support,Field maintenance and repair service |

| Dimension(l*w*h): | 9000*1500*1500MM |

| Control system: | fully automatic |

| Name: | metal floor decking roll forming machines |

| Company Info. |

| DLY Metal Roofing Machine |

| View Contact Details |

| Product List |

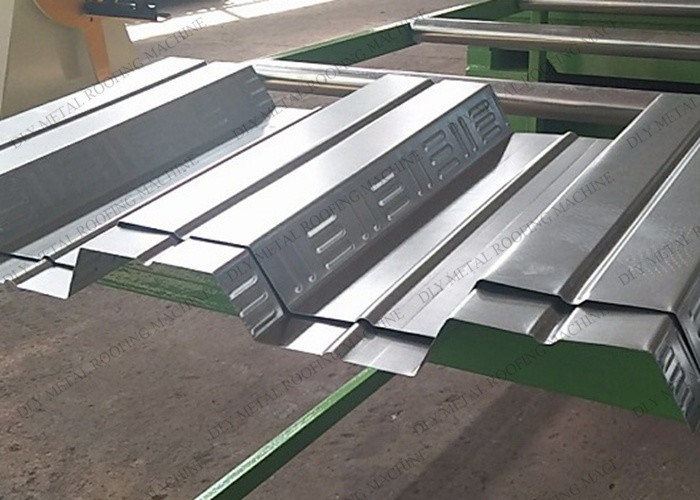

0.8mm - 1.3mm Metal Decking Floor Deck Roll Forming Machine With One Year Guarantee

1. description of Floor Deck Sheet Roofing Machine

There are different steel deck roll forming machines manufacturing metal decks for different applications, and the configuration or components of each machine vary accordingly, for example, some deck machine have embossing rolling tools while some others do not. Generally a metal deck or steel deck roll forming machine consists of a 5TON manual de-coiler, feeding guide, an electrical entry shearing with 0.75KW motor power,a roll forming part including an embossing tools, transmission system, hydraulic system, a PLC control cabinet, a hydraulic oil pump and runout tables to support the final products.

2. Advantage of Floor Deck Sheet Roofing Machine

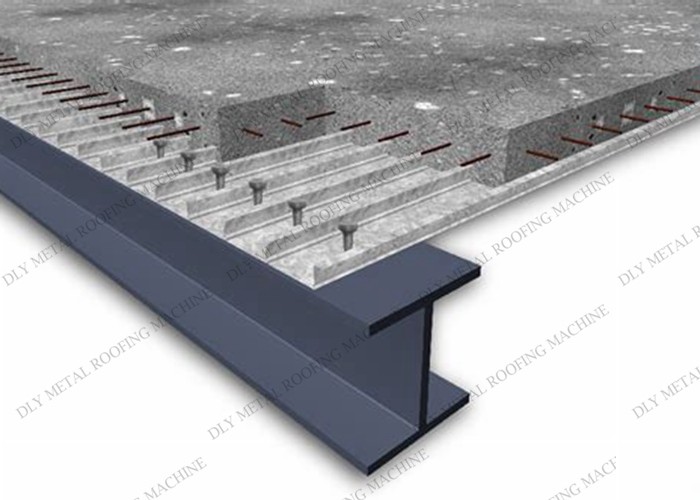

1) Adapting to the requirements of rapid construction of the main

steel structure, it can provide a firm working platform in a short

time,

and can be used to lay the profiled steel plate on multiple floors,

and the flow water construction of the layered concrete slab

2) In the use stage, the floor deck is used as the tensile

reinforcement of the concrete slab, which also improves the

rigidity of the slab

and saves the amount of steel and concrete. The floor deck is

generally V-shaped, U-shaped, trapezoidal, and the convex part of

the concrete is much less.

Unlike the soil board, it is a flat plate. The floor deck can

generally save one-third of the concrete. Now the concrete is

expensive.

3) The embossing on the surface of the profiled board creates the

greatest bonding force between the floor deck and the concrete,

so that the two form a whole, with stiffening rib, make the floor

deck system has high bearing capacity.

4) Under cantilever conditions, the floor slab is only used as a

permanent formwork.

The length of the cantilever can be determined according to the

section characteristics of the floor panel.

In order to prevent the cracking of the cantilever plate, it is

necessary to match the negative reinforcement at the support

according

to the design of the structural engineer.

3. profile drawing of Floor Deck Sheet Roofing Machine

4. details of Floor Deck Sheet Roofing Machine

|