| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Double Layer Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | RF-ST |

| Certification: | CE, SGS, ISO |

| Place of Origin: | Wuxi, China |

| MOQ: | 1 set |

| Price: | negotiable |

| Supply Ability: | 10 sets/month |

| Delivery Time: | 60 days after deposit |

| Packaging Details: | Film and steel |

| Steel thickness: | 0.17-0.45mm PPGI Color Steel Sheet,Galvanized Sheet |

| Forming speed: | 0-12m/min |

| Roller stations: | 20 rollers/ 18 rollers |

| Roller material: | 45# steel |

| Shaft diameter: | 76mm |

| Main shaft diameter: | 7.5Kw |

| Cutting blade material: | cr12 with quenched treatment |

| Usage: | metal roof and wall |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

1220mm Coil Width Corrugated Trapezoidal IBR Sheet Roofing Double

Layer Roll Forming Machine

1. Technical Parameter

| Product name | Corrugated & trapezoidal sheet double layer roofing machine |

| Base material | GI/GL,PPGI/PPGL,Aluminum coil |

| Thickness | 0.17mm-0.45mm |

| Effective Width | 1220mm and 1000mm |

| Roller station | 18 stations/20 stations |

| Roller material | 45# steel with quenched |

| Roller driven type | By 1 inch chain |

| Color | According to customer requirements |

| Control System | Worldwide Famous Brand PLC (Panasonic, Siemens, Delta, etc) |

| Power | 7.5KW |

| Frame | 350 H steel |

| Cutting drive | Hydraulic drive |

| Cutting&Hydraulic type | Hydraulic pump station :4kw Blade material:Cr12mov HRC:58-62 |

| Feature | Building metallic materials have excellent performance of decoration, corrosion resistance etc, easy to operate, energy saving,flexible manufacturing,high productivity, eco-friendly. |

2. Machine List

5T passive de-coiler | 1 set |

Guiding Platform | 1 set |

| Double manual pre-cutting device | 1 set |

Main roll forming | 1 set |

Hydraulic cutting device | 1 set |

PLC Control box | 1 unit |

Hydraulic station | 1 unit |

4 meters passive Out table | 1 unit |

Safety cover | 1 unit |

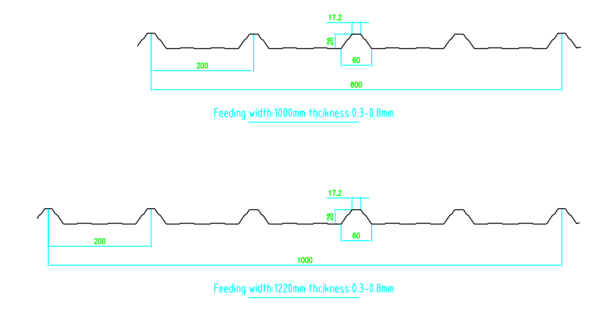

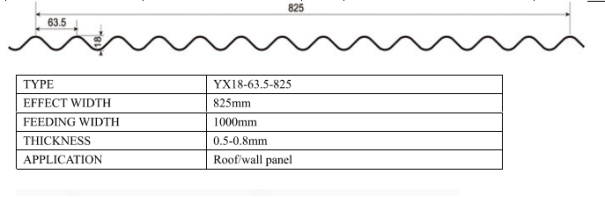

3. Profile Drawing

4. Main Features

1.This double roll forming machine can produce two different

profiles with one machine, sharing same machine base frame,

un-coiler, PLC control system, which can much save of your cost.

2.More reasonable forming process design; More roller steps with

competitive price.

3.The whole line consists of un-coiler, double pre-cutting system,

feeding system, roll forming machine with protect guarding cover,

post-cut device, PLC control system, and so on.

5. Machine Photo

|