| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

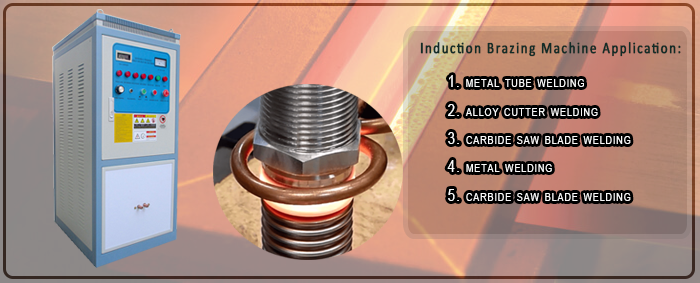

| Categories | Induction Heating Machine |

|---|---|

| Brand Name: | Lanshuo |

| Model Number: | LSW-50 |

| Certification: | CE ISO |

| Place of Origin: | Henan Province,China |

| MOQ: | 1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 3000 set per year |

| Delivery Time: | 5-10 working days |

| Packaging Details: | wooden package |

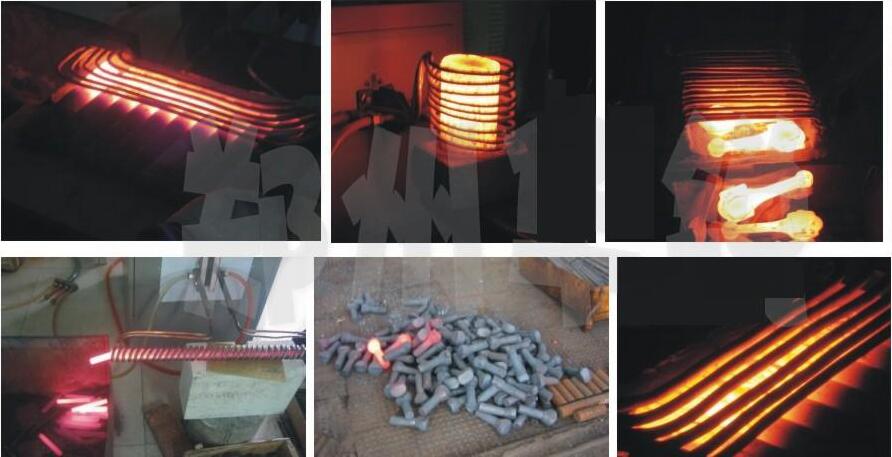

| Application: | quenching,annealing,Forging,Heat Treatment,for metal heating/hot forging |

| Product name: | induction heating machine 50 KW |

| Name: | induction heating machine |

| Working frequency: | 18-35Khz |

| Input current: | 750A |

| Heating temperature: | 800-1250℃ |

| Usage: | hardening,metal forging |

| Frequency: | High Frequency |

| Power: | 50KW |

| Output power: | 500V |

| Company Info. |

| Zhengzhou Lanshuo Electronics Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

1. Feature of high frequency heating equipment:

The fastest heating speed is less than 1 second, and the heating speed can be adjusted and controlled. The thermal efficiency is more than 95%, so it is more energy-saving than other heating methods (such as gas, oxygen, acetylene, coking coal, electric furnace, high-frequency electronic tube, etc.).

The surface of the workpiece is heated evenly and the temperature rises quickly, which reduces the oxide layer on the surface of the workpiece and the deformation of the workpiece.

The equipment has an automatic setting function, and the operation can be completed by one person, thereby reducing the number of processes and improving efficiency. No noise, pollution and open fire, it is easier to meet the requirements of environmental protection and fire protection.

The device is small in size, light in weight, and takes up less than half a cube of space, making it easy to move and move.

2. Induction heating heating forging machine technical parameters:

| Model | LSW-50 |

| Working voltage | 3 phase 380V, 50/60HZ or customized |

| Max input current | 75A |

| Max input power | 50KW |

| Oscillation frequency | 18-25KHZ |

| Duty cycle | 100% |

| Cooling water flow | ≥ 0.1Mpa, ≥32L/min |

| Weight | 120KG |

| Dimension(L*W*H) | 550*650*1260mm |

Induction heating forging machine whole set machine list item:

| Item No. | Name | Specification | Quantity |

| 1 | LSW-50 induction brazing machine | - | 1 set |

| 2 | induction coil | - | 1 pcs |

| 3 | foot switch | - | 1 pcs |

| 4 | user manual | - | 1 copy |

3. Feature of high frequency induction heating forging machine:

1. Adopt IGBT solid state inverter technology, high efficiency and

energy saving, high output power.

2. Digital phase-locking technology to achieve automatic frequency

tracking.

3. Perfect function, high reliability and easy maintenance.

4. Modular design, simple installation, convenient operation, no

need to debug.

5. 100% negative performance rate design, can work continuously for

24 hours.

6. It can replace other heating methods (such as gas, coking coal,

oil furnace, electric furnace, high-frequency electronic tube,

etc.), energy saving and environmental protection.

7. Resonance frequency conversion technology makes the whole

machine efficiency ≥95%, and the efficiency is high.

Main Feature of high frequency induction heating quenching machine:

1. It adopts the most advanced MOS, IGBT frequency conversion

control technologies to realize automatic tracking of frequency.

2. It has the constant current and power control function, which

can significantly optimize metal heating process, realize the high

efficiency and fast heating and bring into play the superior

performance of the products.

3. About ten types fault protection and display of over-current,

over-voltage, water shortage and phase missing can provide higher

reliability and durability.

4. It is safe and reliable, and requires no equipments of ten

thousand voltage, and thus can ensure the safe operation.

5. It is available for infrared temperature measurement, which can

realize the automatic control of temperature, improve the heating

performance and simplify the manual operation.

The basic composition of high-frequency heating equipment includes induction coil, AC power supply and workpiece. According to different heating objects, the induction coil can be made into different shapes. The coil is connected to the power supply, and the power supply provides alternating current for the coil. The alternating current passing through the coil generates an alternating magnetic field passing through the workpiece, and the magnetic field causes the workpiece to generate eddy currents to heat it.

|