| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cryogenic Furnace |

|---|---|

| Brand Name: | DJL |

| Model Number: | DJL-SLX-1200H |

| Certification: | ISO9001,CE |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 set per month |

| Delivery Time: | 30 working days |

| Packaging Details: | wooden cases |

| Lid opening way: | Upper opening lid |

| Control method: | PLC |

| Working temperature: | -196℃ to +250℃ |

| Inner size: | 1000*600*600mm |

Modular Combined Cryogenic Furnace Deep Cryogenic Furnace For

Axletree/Bearing

Product description

Cryogenic is generally in the temperature range from -40℃ to -196℃.

Cryogenic treatment generally uses liquid nitrogen refrigeration,

and the method of ultra-low temperature treatment of the workpiece

at a temperature below -130°C effectively improves the toughness of

the workpiece. There are two methods of cryogenic treatment: One is

that the workpiece is directly placed in liquid nitrogen. This

method has a large thermal shock, which is easy to cause cracking

of the workpiece; The other is the equipment produced by our DJL

company, the cryogenic treatment of liquid nitrogen gasification.

The processing temperature can reach -196℃, the processing effect

is good, the toughness of the workpiece is greatly improved, and

the workpiece will not be damaged.

The tempering furnace is used for general metal parts to be

tempered in the air and used for quenching, annealing and aging

heat treatment of light alloy parts such as aluminum alloy die

castings, pistons and aluminum plates. The outer shell is made of

section steel and steel plate welded together. The trolley is

welded by section steel and steel plate, the trolley reduces the

heat radiation and convection loss through the soft contact with

the furnace lining and the sand seal mechanism, and effectively

guarantees the sealing of the furnace body.

Specification

| Model | Inner capacity size | Boundary dimension | Volume (L) | Refrigerating capacity | Delivery cycle (Week) |

| SLX-544 | 500 * 400 * 400 | 1330 * 700 * 915 | 80 | 150 | 2 ~ 4 |

| SLX-755 | 700 * 500 * 500 | 1530 * 800 * 960 | 175 | 500 | 3 ~ 6 |

| SLX-966 | 900 * 600 * 600 | 1730 * 900 * 1060 | 324 | 650 | 3 ~ 6 |

| SLX-1077 | 1000 * 700 * 700 | 1930 * 1250 * 1210 | 490 | 1000 | 4 ~ 6 |

| SLX-1499 | 1400 * 900 * 900 | 2230 * 1200 * 1360 | 1134 | 1500 | 4 ~ 6 |

In addition to the above specifications, we can also customize

various non-standard tank according to customers' requirements. Our

products are continuously updated, if there is a product

improvement, you can log in to our company's website or call for

consultation at any time!

The characteristics of DJL liquid nitrogen cryogenic treatment

machine

1. With extreme low temperature, the lowest temperature is -196℃,

which can greatly meet the requirements of cold assembly process.

2. Adopting the latest intelligent temperature control system, it

can set the required temperature parameters, cooling, freezing and

holding time according to the process requirements, and it has the

function of process recording and remote monitoring.

3. The machine adopts advanced liquid nitrogen dispersing

technology and unique cold air circulation system to make full use

of liquid nitrogen cooling energy, so that the workpiece can be

cooled evenly, stably and quickly.

* To improve the hardness and strength of workpiece

* To improve the corrosion resistance of workpiece

* To improve the internal stress distribution of workpiece

* To ensure the dimension accuracy of workpiece

Our partner

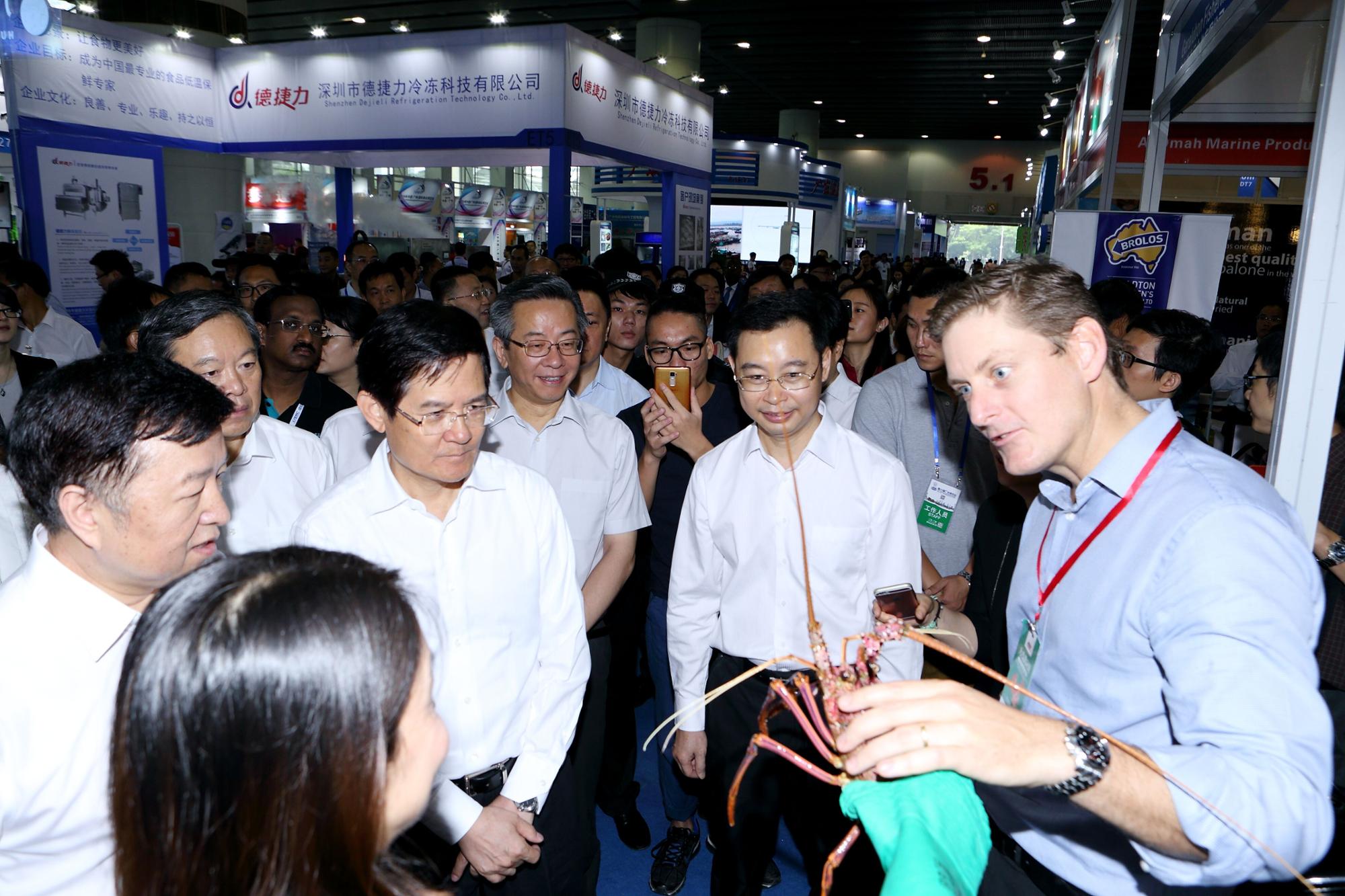

Exhibition

|