| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cryogenic Furnace |

|---|---|

| Brand Name: | DJL |

| Model Number: | DJL-SLX-1000H |

| Certification: | ISO9001,CE |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 20 set per month |

| Delivery Time: | 30 working days |

| Packaging Details: | wooden cases |

| Lid opening way: | Upper opening lid |

| Control method: | PLC |

| Working temperature: | -196℃ to +250℃ |

| Inner size: | 500*650*650mm |

| Capacity: | customized |

| power: | 6 kw |

| voltage: | 440v/50hz |

DJL Ultra Low Temperature Cryogenic Furnace Equipment For Heat

Treatment Industry

Product description

Most of the hardware machinery enterprises have outsourced heat

treatment processes, but they can control cryogenic treatment as a

core process to ensure quality in their own hands. Since cryogenic

treatment must be tempered to ensure the elimination of stress and

other performance adjustments, therefore, cryogenic treatment

equipment must match tempering equipment with high reliability and

good temperature uniformity in order to maximize the effectiveness

of cryogenic. And more equipment means more space resources, labor

and procurement cost occupation, in order to optimize the use of

customer resources, DJL especially launched a comprehensive

solution for the above scenarios——Cryogenic Furnace With Tempering

Integrated Furnace For Shafts Heat Treatment Industry

Application range of cryogenic with tempering integrated furnace:

it is used for cryogenic treatment of various metal materials such

as shafts, micro motor shafts, bearings, automotive bearings,

gears, hard alloy, aluminum alloys, copper alloys, hardware, tools,

springs, high-speed steel, working tools, cutters, molds, saw

blades, oil pumps, oil nozzles,golf club head, rollers,diamonds,

mines, geological drill, steel sheets, mechanical parts, aerospace,

etc. Various parts of interference cooling and ultra-low

temperature environment simulation and other applications.

Specification

| Model | Inner capacity size | Boundary dimension | Volume (L) | Refrigerating capacity | Delivery cycle (Week) |

| SLX-544 | 500 * 400 * 400 | 1330 * 700 * 915 | 80 | 150 | 2 ~ 4 |

| SLX-755 | 700 * 500 * 500 | 1530 * 800 * 960 | 175 | 500 | 3 ~ 6 |

| SLX-966 | 900 * 600 * 600 | 1730 * 900 * 1060 | 324 | 650 | 3 ~ 6 |

| SLX-1077 | 1000 * 700 * 700 | 1930 * 1250 * 1210 | 490 | 1000 | 4 ~ 6 |

| SLX-1499 | 1400 * 900 * 900 | 2230 * 1200 * 1360 | 1134 | 1500 | 4 ~ 6 |

In addition to the above specifications, we can also customize

various non-standard tank according to customers' requirements. Our

products are continuously updated, if there is a product

improvement, you can log in to our company's website or call for

consultation at any time!

The characteristics of DJL liquid nitrogen cryogenic treatment

machine

1. With extreme low temperature, the lowest temperature is -196℃,

which can greatly meet the requirements of cold assembly process.

2. Adopting the latest intelligent temperature control system, it

can set the required temperature parameters, cooling, freezing and

holding time according to the process requirements, and it has the

function of process recording and remote monitoring.

3. The machine adopts advanced liquid nitrogen dispersing

technology and unique cold air circulation system to make full use

of liquid nitrogen cooling energy, so that the workpiece can be

cooled evenly, stably and quickly.

* To improve the hardness and strength of workpiece

* To improve the corrosion resistance of workpiece

* To improve the internal stress distribution of workpiece

* To ensure the dimension accuracy of workpiece

Our partner

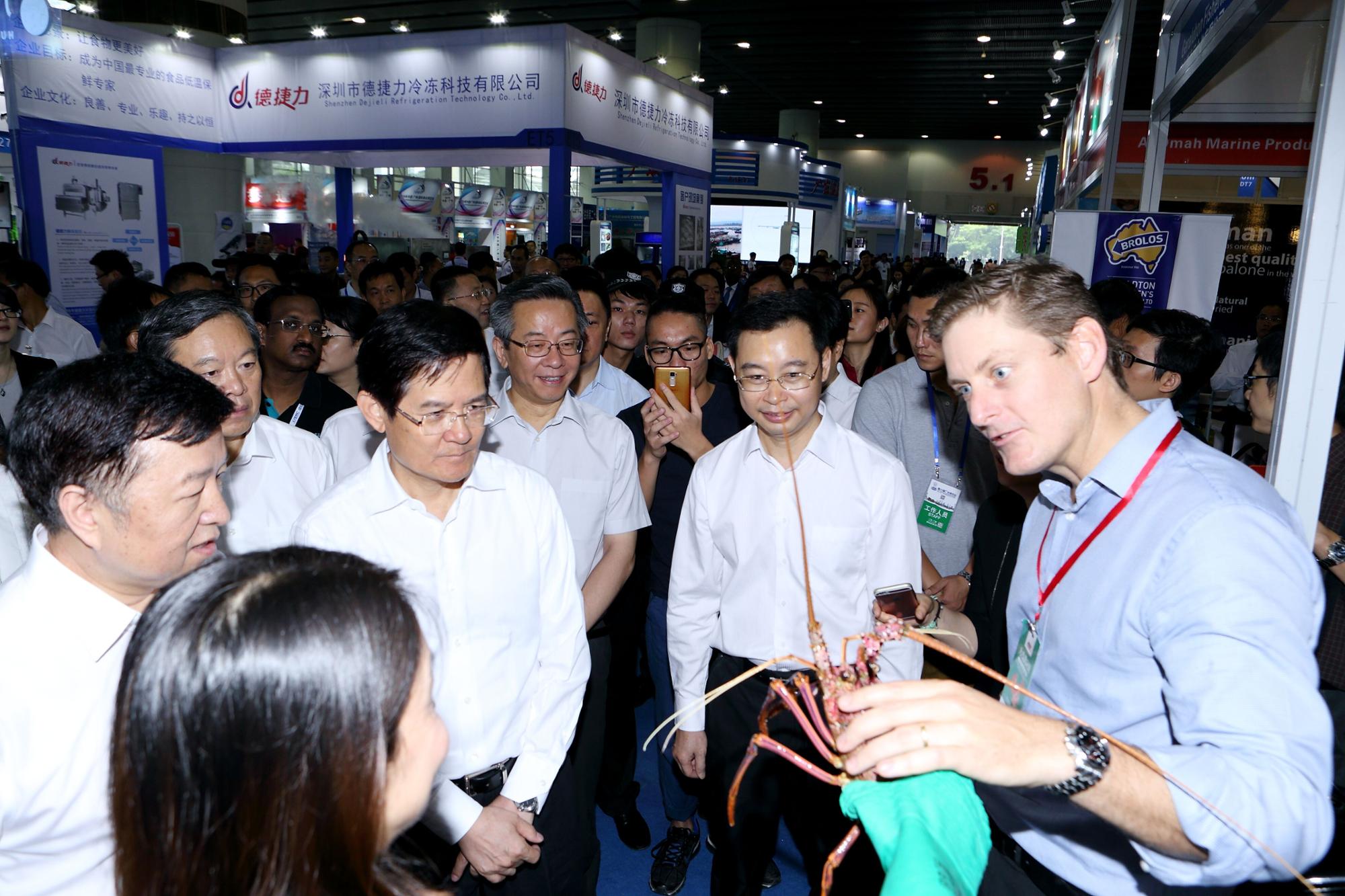

Exhibition

|