| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Silicon Nitride Ceramics |

|---|---|

| Brand Name: | ZG |

| Model Number: | MS |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 piece |

| Price: | Negotiation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram, MoneyGram |

| Supply Ability: | 10000 pieces per month |

| Delivery Time: | 5-8 working days |

| Packaging Details: | Strong wooden box for global shipping |

| Material: | Silicon Nitride Si3N4 |

| Size: | Customized |

| Color: | Black |

| Features: | high hardness; high corrosion resistance; low density; stability in a wide range of temperatures; precision machining capability. |

| Company Info. |

| HENAN ZG INDUSTRIAL PRODUCTS CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

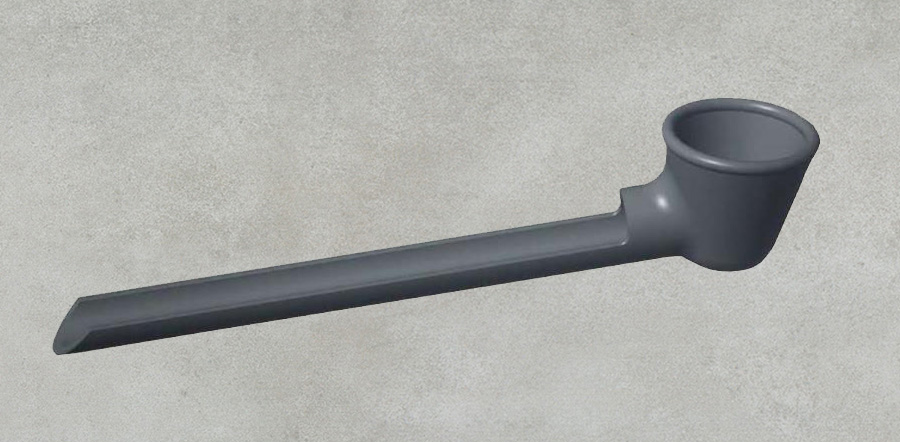

High-performance silicon nitride ceramic materials developed for the aluminum industry has significantly improved thermal and mechanical properties than similar products. On this basis, the "L-shaped high thermal conductivity submerged heating "Appliance" will bring revolutionary progress to aluminum industrial equipment.

The silicon nitride-lined launder pioneered by "Silicon Poly" solves the troubles that have been plagued workers in the aluminum industry.The silicon nitride lining does not stick to aluminum water, so the launder almost does not need to be cleaned, which greatly reduces the labor intensity of the workers;

Advantage:

Compared with the casting material launder, the service life is greatly extended.

The launder does not need to be sprayed with anti-stick coating, which ensures the purity of molten aluminum;

Silicon Nitride Related Data

| Main component | 99%Al2O3 | S-SiC | ZrO2 | Si3N4 | ||

| Physical Property | Density | g/cm3 | 3.9 | 3.1 | 6 | 3.2 |

| Water Absorption | % | 0 | 0.1 | 0 | 0.1 | |

| Sinter Temperature | °C | 1700 | 2200 | 1500 | 1800 | |

| Mechanical Property | Rockwell Hardness | HV | 1700 | 2200 | 1300 | 1400 |

| Bend Strength | kgf/mm2 | 3500 | 4000 | 9000 | 7000 | |

| Compression Intensity | Kgf/mm2 | 30000 | 20000 | 20000 | 23000 | |

| Thermal Property | Maximum working temperature | °C | 1500 | 1600 | 1300 | 1400 |

| thermal expansion coefficient 0-1000°C | /°C | 8.0*10-6 | 4.1*10-6(0-500°C) | 9.5*10-6 | 2.0*10-6(0-500°C) | |

| 5.2*10-6(500-1000°C) | 4.0*10-6(500-1000°C) | |||||

| Thermal Shock resistance | T(°C) | 200 | 250 | 300 | 400-500 | |

| Thermal Conductivity | W/m.k(25°C | 31 | 100 | 3 | 25 | |

| 300°C) | 16 | 100 | 3 | 25 | ||

| Electrical Property | Resisting rate of Volume | ◎.cm | ||||

| 20°C | >1012 | 106-108 | >1010 | >1011 | ||

| 100°C | 1012-1013 | – | – | >1011 | ||

| 300°C | >1012 | – | – | >1011 | ||

| Insulation Breakdown Intensity | KV/mm | 18 | semiconductor | 9 | 17.7 | |

| Dielectric Constant (1 MHz) | (E) | 10 | – | 29 | 7 | |

| Dielectric Dissipation | (tg o) | 0.4*10-3 | – | – | – | |

|

|