| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Floor Deck Roll Forming Machine |

|---|---|

| Brand Name: | SUSSMAN |

| Model Number: | SS-FD |

| Certification: | SGS,CE ,ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T, |

| Supply Ability: | 10 sets per month |

| Delivery Time: | 60-90 working days |

| Packaging Details: | Standard Packing with film coated and steel wire fixed |

| Name: | Galvanized Steel Floor Deck Roll Forming Machine |

| Material: | Galvanized steel |

| material thickness: | 0.8-1.2mm |

| Forming stations: | 28 stations |

| Roller material: | Gcr15, Quench HRC58-62 Plated Chrome |

| Dirve system: | Chain drive |

| power supply: | 380V, 50Hz, 3Phase |

| Forming speed: | up to10-12m/min |

| Machine weight: | about 8 tons |

| Machine Size: | 8mx0.88mx1m |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

PLC Control 1.5mm Thickness Floor Decking Roof Deck Roll Forming Machine

Floor Deck Making Machine Technical Parameter

Item NO | Description | |

1 | Steel Thickness | 0.75-1.2mm |

2 | Product Line Speed | up to 12 |

3 | Roller station | 28 stations |

4 | Roller Material | 45# steel |

5 | Shaft diameter | 90 |

6 | Main Motor Power | 18.5kw |

7 | Hydraulic cutting Power | 7.5KW |

8 | Hydraulic pressure | 12KW |

9 | Power Supply | 380V, 50HZ,3 phase |

10 | Tolerance | 1.5mm |

11 | Material of cutting | Cr12 |

12 | Control system Panasonic | PLC with touch screen |

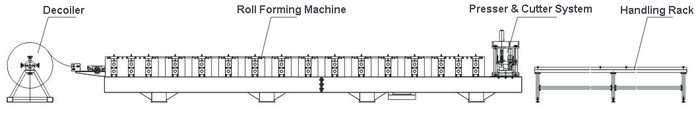

Machine List

No | Name | quantity |

1 | 5 ton passive de-coiler | 1 set |

2 | Main roll forming machine | 1 set |

3 | PLC system | 1 unit |

4 | Hydraulic station | 1 unit |

5 | Out tables | 2 units |

Working Flow of Machine

Uncoiling—Feeding&Leveling--Roll forming—Cutting—Products collecting

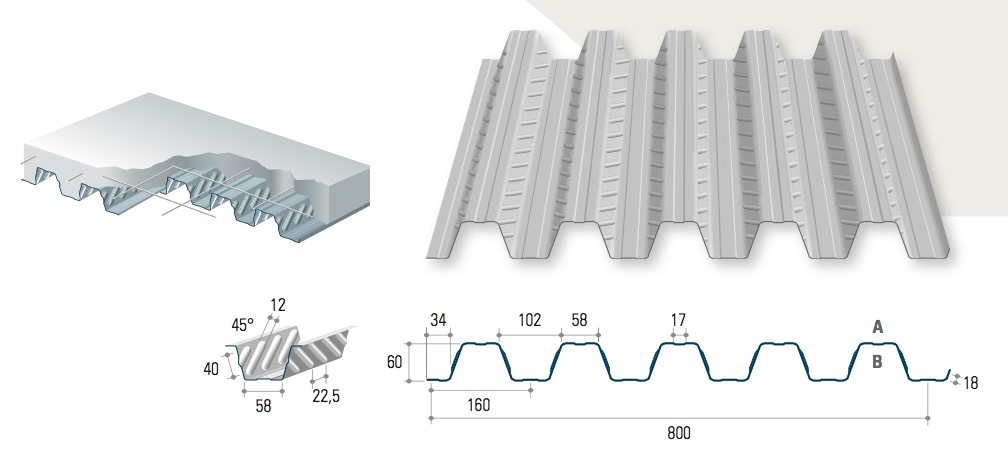

Standard Profile Drawing of product

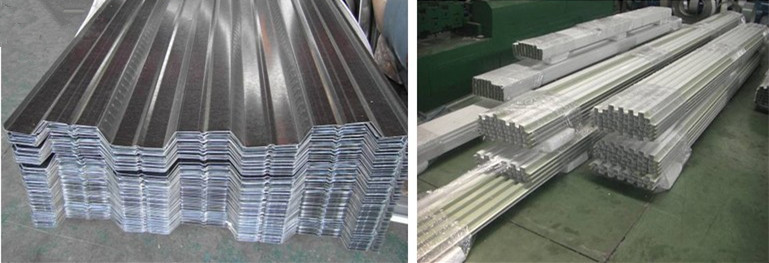

Machine Photo

Application

Loading Pictures

Quality Control

1.We strictly control the quality of raw materials and we can offer

inspection certificate of our raw materials for you.

2. We do manufacturing strictly according to the technological

processes. Besides, we carry out sampling inspection for our

products.

3. All of our workers have received relevant quality management

training so that the quality of products can be ensured.

Our goal is to offer the best solution for our customers, supply

high quality machine and good service with reasonable price. We

sincerely hope to cooperate with worldwide customers for mutual

success.

|