| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Machining Parts |

|---|---|

| Brand Name: | Custom made products |

| Model Number: | CNC Machining Parts |

| Certification: | ISO9001:2008 |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 500000 PCS / Year |

| Delivery Time: | 5~8 workdays |

| Packaging Details: | Each product packed with Single bubble bag or single foam plastic bag into the Carton or wood case/iron case as per the customer's request |

| Material: | Aluminum/stainless steel/brass/steel/titanium etc. |

| Applications: | EDC tools and product |

| Finish options: | Sandblasted/anodized/brush/polish/plating/heat treatment/coating/laser engraving etc. |

| Quality Inspection Tools: | Two Dimensional Measuring Instrument/Gauges |

| Sample Production Time: | 5~10 workdays |

| Name: | Custom manufacturing CNC turning Machined Aluminum Parts |

| Length: | 75mm or custom dimension |

| Diameter: | 18mm or as per drawing |

| Company Info. |

| Zoe CNC Machining Co., Ltd. |

| View Contact Details |

| Product List |

Custom manufacturing CNC turning Machined Aluminum Parts for EDC tools

Production Description:

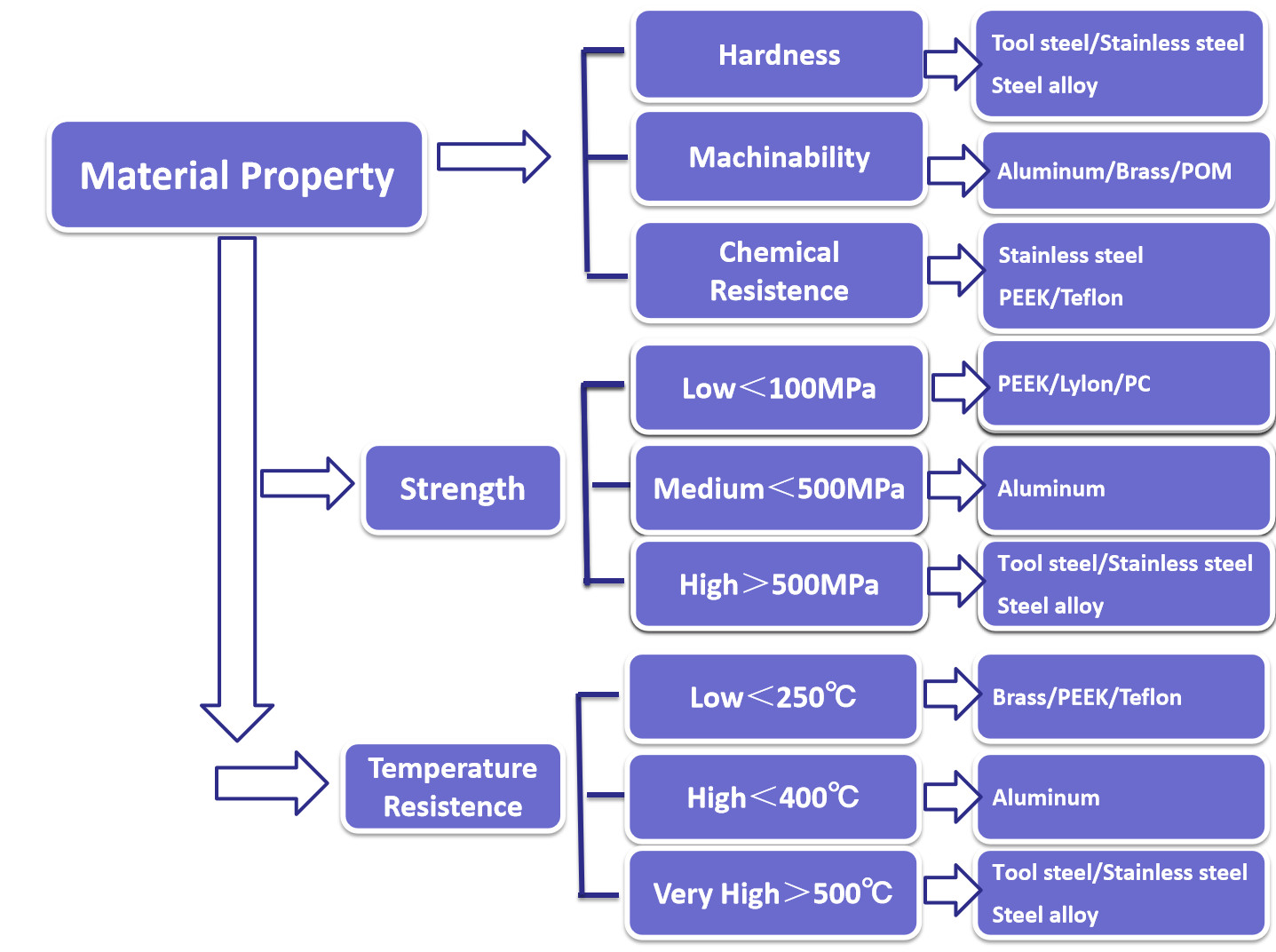

| Material Options | Aluminum, Copper, Brass, Titanium, Carbon steel, Stainless Steel, stainless steel, Kovar, Tungsten steel, Copper, Brass, Titanium, POM, PTFE, PEEK, POM, etc. |

| Surface Finishes | Polishing, Powder coating, Spraying, Anodising, Zinc Plating Nickel Plating, Chrome Plating and etc. |

| Heat treatment | Annealing, Normalizing, Tempering, Quenching, quenching, and High-temperature tempering, High-frequency heat treatment, Tenifer QPQ and etc. |

| Machine Accuracy | +/-0.005mm~ |

| Inspection Accuracy | +/-0.003mm~ |

| Equipment | a) CNC Machining Center b) CNC Turning and Milling c ) Surface grinder d) CNC Drilling and Bending e) CNC Punching Machine f) Laser cutting machine g) Laser engraving logo |

| Preferred Industries | a) Communication Equipment b) Photo gear products c) Auto accessories d) Electronic hardware accessories e) Mechanical Equipment f) Other customized Parts |

| Quality Control | Certificates: RoHS, ISO9001:2008, SGS. IQC → IPQC → OQC/FQC → CQE → Audit & Training. » Plant Audit and Qualified by world famous company » Strict Quality Management Procedure with Traceability |

Our advantage:

| 1. Fair Pricing |

| 2. Reliable quality |

| 3. Safe shipping ways |

| 4. Outstanding after-sale service |

| 5. Fast production time and complete professional CNC Machining service |

*Come and get a nice quotation from us now!

Note: Workable 3D Drawing Formats: STEP/IGS/X_T/STL/SOLIDWORKS etc, 2D Drawing with PDF will do.

|