| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Organic Fertilizer Production Machine |

|---|---|

| Brand Name: | Zhengzhou Huaqiang |

| Certification: | ISO |

| Place of Origin: | Zhengzhou city, China |

| MOQ: | 1 set |

| Price: | US$4000-220000 per set |

| Payment Terms: | T/T, L/C, Western Union, MoneyGram |

| Supply Ability: | 50 sets per month |

| Delivery Time: | 10-15 working days |

| Packaging Details: | Small machines are packed in wooden box,production line or large quality machines are packed in containers |

| Model Number: | ZL series |

| Raw materials: | Agricultural waste,animal manure etc |

| After-sale service: | Field installation in customer's plant |

| Application: | Organic/ Bio organic fertilizer making |

| Advantages: | Low investment,environment protecting |

| Voltage: | 380V / 220V / 415V Etc... |

| Condition: | New |

| Warranty: | 12 months |

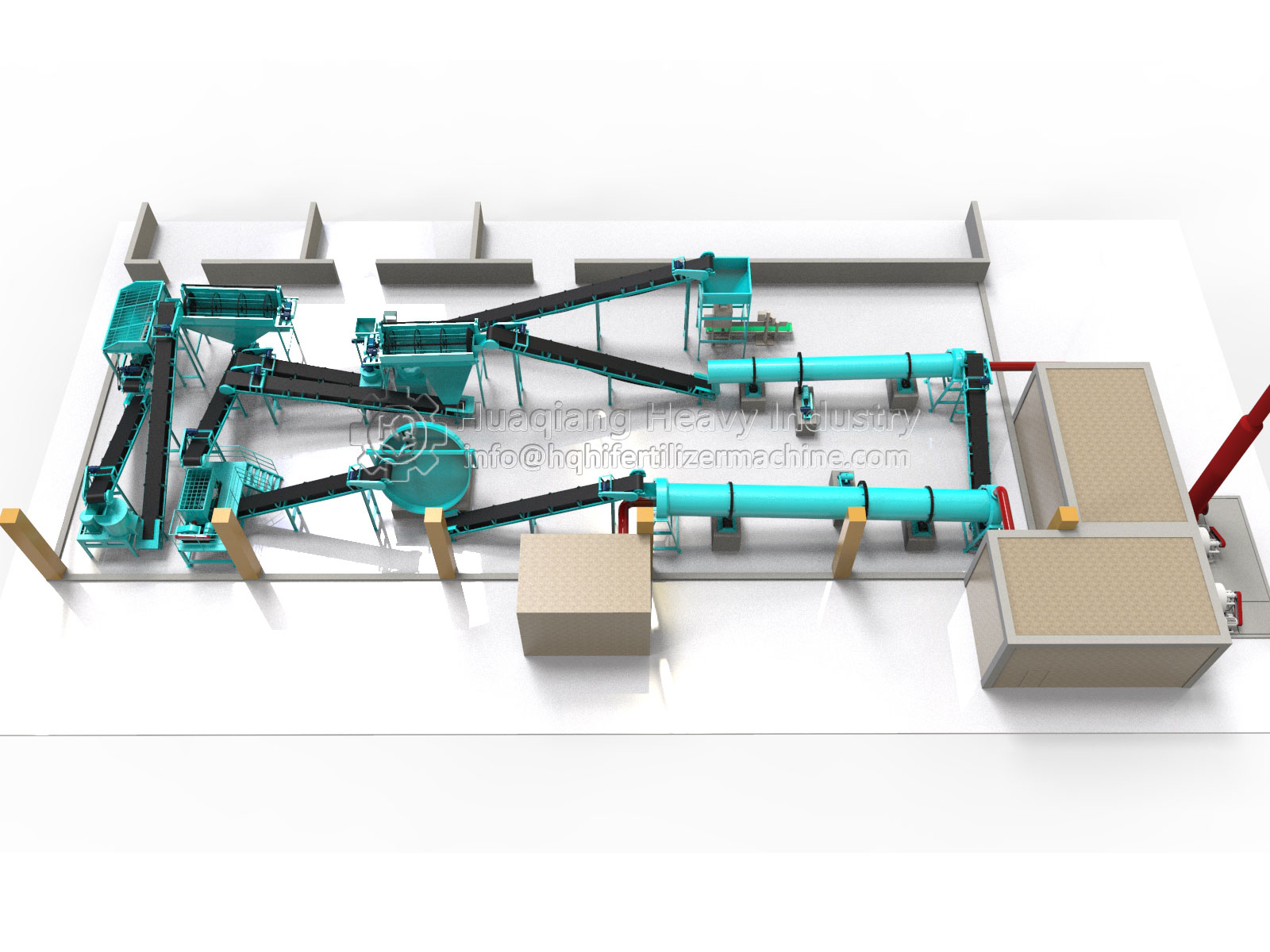

5T/H Bio Organic Fertilizer Pan Granulating Production Line

Equipment

Introduction of 5T/H Bio Organic Fertilizer Pan Granulating Production Line

Equipment

Organic fertilizer production line is to process the organic

substance into the organic fertilizer that is derived from animal

waste, industrial waste etc. It not only reduces environment

pollution, but also makes rational use of resources.

Raw materials of 5T/H Bio Organic Fertilizer Pan Granulating Production Line

Equipment

In organic fertilizer production line, there are many common

organic raw materials.

1. Animal manure: chicken manure, cow dung, sheep manure, horse

dung, rabbit dung, etc.

3. Industrial waste: vinasse, vinegar residue, sugar residue, and

furfural residue, etc.

4. Agricultural residues: crop straws, bean pulp, cottonseed meal,

etc.

5. Municipal sludge: river sludge, sewage sludge.

Working Process of 5T/H Bio Organic Fertilizer Pan Granulating Production Line

Equipment

There organic fertilizer production line needs several procedures:

1. Composting: it’s a fermentation process to make the organic raw

materials into compost.

2. Crushing and mixing: In the part, the fertilizer crusher machine

will be used to crush large fertilizer pieces into powder, and then

mixer machine will be used to mix the powder evenly before

granulating.

3. Granulating: This is core part in organic fertilizer production

line. Here powdery organic fertilizer will be granulated into

pellets.

4. Drying and cooling: In this step, water content of organic

fertilizer pellets will be reduced, so as to make the pellets more

compact and improve storage time.

5. Screening: The screening machine here used to separate

unqualified organic fertilizer pellets from qualified pellets.

6. Packaging: In this procedure, the fertilizer pellets will be

packed.

Mainly equipment in 5T/H Bio Organic Fertilizer Pan Granulating Production Line

Equipment

| Number | Name | Function |

| 1 | Compost turning machine | Used for fermentation of organic fertilizer raw materials |

| 2 | Half wet materials crusher | Crushing high water content compost fertilizer |

| 3 | Mixer machine | Mixing organic fertilizer powder with other material or water |

| 4 | Organic fertilizer granulator | Making ball shape granules fertilizer |

| 5 | Dryer machine | After granulating, granules moisture is about 30%-40%, need to dry with hot air, this machine need to work with Burning Furnace to supply hot air. |

| 6 | Cooler machine | After drying, granules temperature is high with moisture, need to cool with air. |

| 7 | Screener machine | Separate different size granules, products go to packing machine. Oversize granules crush and re-granulate, small particles re-granulate. |

| 8 | Belt conveyor | Connect the machines in the line, have many types, like Belt conveyor, Screw conveyor, Bucket elevator etc... |

| 9 | Packing machine | Packing granules in bags, avalible 5-10kgs & 20-50kgs & 500-1000kgs |

| Auxiliary machines, optional | ||

| 10 | Burning furnace | Work with Dryer machine, burning fuel to supply hot air, fuel type:Coal/Natural gas/Wood/Diesel/Biogas etc... |

| 11 | Dust collector | 1.Client build the Dust collector room according to the drawing. 2.Use Cyclone Dust collector. To clean the air, prevent environment |

| 12 | Coating machine | Granules coating with auti-caking agent, slow release agent, Bacteria etc... |

| 13 | Installation accessories | Platform, Ladder, Stands etc... |

|