| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Organic Fertilizer Production Machine |

|---|---|

| Brand Name: | Huaqiang |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | US$40000-220000 per set |

| Payment Terms: | L/C, , T/T, Western Union |

| Supply Ability: | 50 sets per month |

| Delivery Time: | 10-15 working days |

| Packaging Details: | Small machines are packed in wooden box,production line or large quality machines are packed in containers |

| Product name: | organic fertilizer production line |

| Raw materials: | organic waste,animal manure etc |

| Capacity: | 1-15t/h |

| Application: | Organic fertilizer,bio-organic fertilizer pellet making |

| Production shape: | Round shape |

| Warranty: | 1 year |

| After-sales Service: | Field installation |

Great Market Demand Factory Direct Supply Organic Fertilizer Production Machine

Introduction to organic fertilizer production line

With the rapid development of the livestock and poultry industry, a large amount of manure and sewage are generated. The harmful elements in these manures are seriously exceeded. It is difficult to treat them in the traditional returning method. In response to this situation, people have developed an organic fertilizer production line that integrates high-efficiency mixers, turning machines, granulators, and other fertilizer production equipment with mobile and high-efficiency solid-liquid separation technology as the core.

Raw materials of organic fertilizer production line

The organic fertilizer production line raw materials are is chicken manure, pig manure etc, and does not contain any chemical ingredients. Chickens and pigs have poor digestion ability and can only consume 25% of the nutrients, while the other 75% of the nutrients in the feed discharged with the feces. The dried product contains nitrogen, phosphorus, potassium, organic matter, amino acids, proteins, and so on.

Working Process of organic fertilizer production line

1. Fermentation process: Fermentation is the basic process of production. In the part, the organic fertilizer raw materials will be fermented into compost

2. Crushing process: it is necessary to use fertilizer crusher to crushing lump materials.

3. Mixing process: Using mixer machine to blending the fertilizer powder in the organic fertilizer production line.

4. Granulation process: It is the most important production process in the organic fertilizer production line.

5. Drying process: After granulating, the granules need to be dried. The moisture of organic fertilizer granules is reduced 10-40%.

6. Cooling process: In order to ensure quality, the particles should be cooling after drying with the help of rotary drum cooling machine.

7. Screening process: Fertilizer screening machine can be used to separate the rejected goods from standard substance.

8. Packaging process: Using fertilizer packing machine to pack final fertilizers.

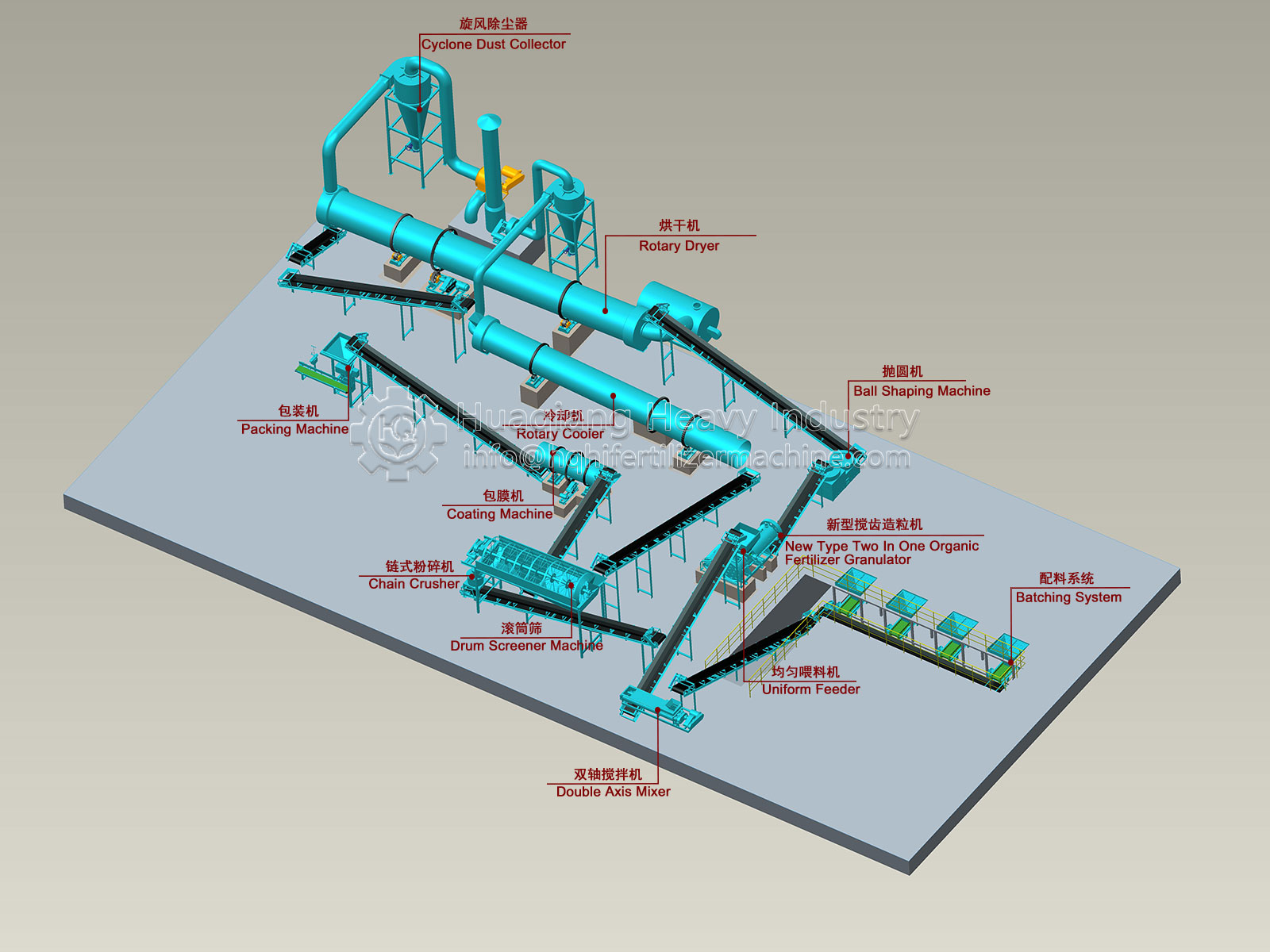

Mainly equipment in organic fertilizer production line

| Number | Name | Function |

| 1 | Compost turning machine | Used for fermentation of organic fertilizer raw materials |

| 2 | Half wet materials crusher | Crushing high water content organic materials |

| 3 | Mixer machine | Mixing organic fertilizer powder |

| 4 | Organic fertilizer granulator | Making organic fertilizer granules |

| 5 | Dryer machine | Drying organic fertilizer granules |

| 6 | Cooler machine | Cooling organic fertilizer granules |

| 7 | Screener machine | Separation of finished products and reclaimed materials |

| 8 | Belt conveyor | Carry on fertilizer raw materials and finished granules |

| 9 | Packing machine | Final products packaging |

Features of organic fertilizer production line

1. Widely application. The organic fertilizer production line can process different raw materials, such as animal manure waste, agricultural waste, ferment materials, etc. All those organic materials can be fermented and granulated into large-output organic fertilizers.

2. Highly automatic and high precision. The batching system and packing machine are controlled by computer to realize automation.

3. High quality, stable performance, easy to operate, highly automatic, long service life. We have taken full consideration of user experience when designing and manufacturing fertilizer machines.

Advantages of organic fertilizer production line

1. The organic production line is low investment and high profit. It is beneficial to promote innocent treatment of waste, utilize resources rationally.

2. Compact structure, stable performance, easy operation and maintenance.

3. The equipment is optional according to customer's actual requirements.

Application of organic fertilizer production line

1. Agricultural waste: Crop straw, vine, soybean mean, mushroom residue, etc.

2. Animal manure: animal manure, such as chicken, pig, cattle, animal residue, such as fish meal, bone meal, silkworm excrement, biogas residue, etc.

3. Industrial waste: Vinasse, vinegar residue, filter mud, herb residue, furfural residue, etc.

|