| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Welding Ceramics |

|---|---|

| Brand Name: | Weite ceramics |

| Model Number: | 020 |

| Certification: | ISO9001 |

| Place of Origin: | Jiangsu, China |

| MOQ: | 50piece |

| Price: | Negotiate |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100000 per month |

| Packaging Details: | carton |

| Name: | Wear-resistant ceramics |

| Material: | Alumina ceramic |

| Features: | Long service life |

| Advantage: | insulation |

| Brand: | Weite ceramics |

| Color: | white |

| Application: | Electronic appliances |

| Company Info. |

| Yixing Weite Chinaware Co., Ltd |

| View Contact Details |

| Product List |

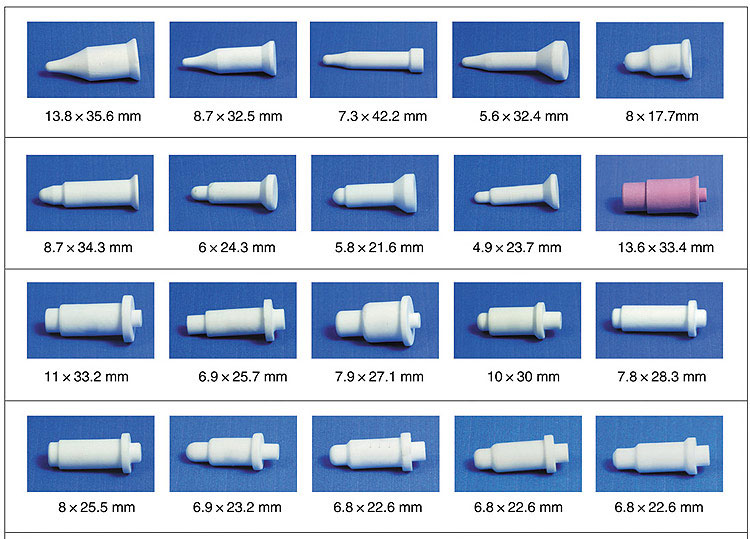

99 porcelain wear-compression resistant ceramic positioning pin

Positioning pins are most widely used in molds. Including stamping

molds, injection molds and so on. Their precision is particularly

high, and if it is only fixed by bolts, it will definitely not

work, so only positioning pins are used to achieve positioning

Alumina has a high hardness and density, with an Inch hardness of 9, which is slightly lower than diamond. The bulk density is generally greater than 3.5 g/cm³, and some can reach 4.0g/cm³. Alumina ceramics are divided into 99 porcelain, 95 porcelain, 90 porcelain, 85 porcelain and other varieties according to different Al2O3 content. Among them, 99 alumina ceramic materials are used to make high-temperature crucibles, refractory furnace tubes and special wear-resistant materials, such as ceramic bearings and ceramic seals. Parts, etc.; 95 alumina ceramics are mainly used as corrosion-resistant and wear-resistant parts.

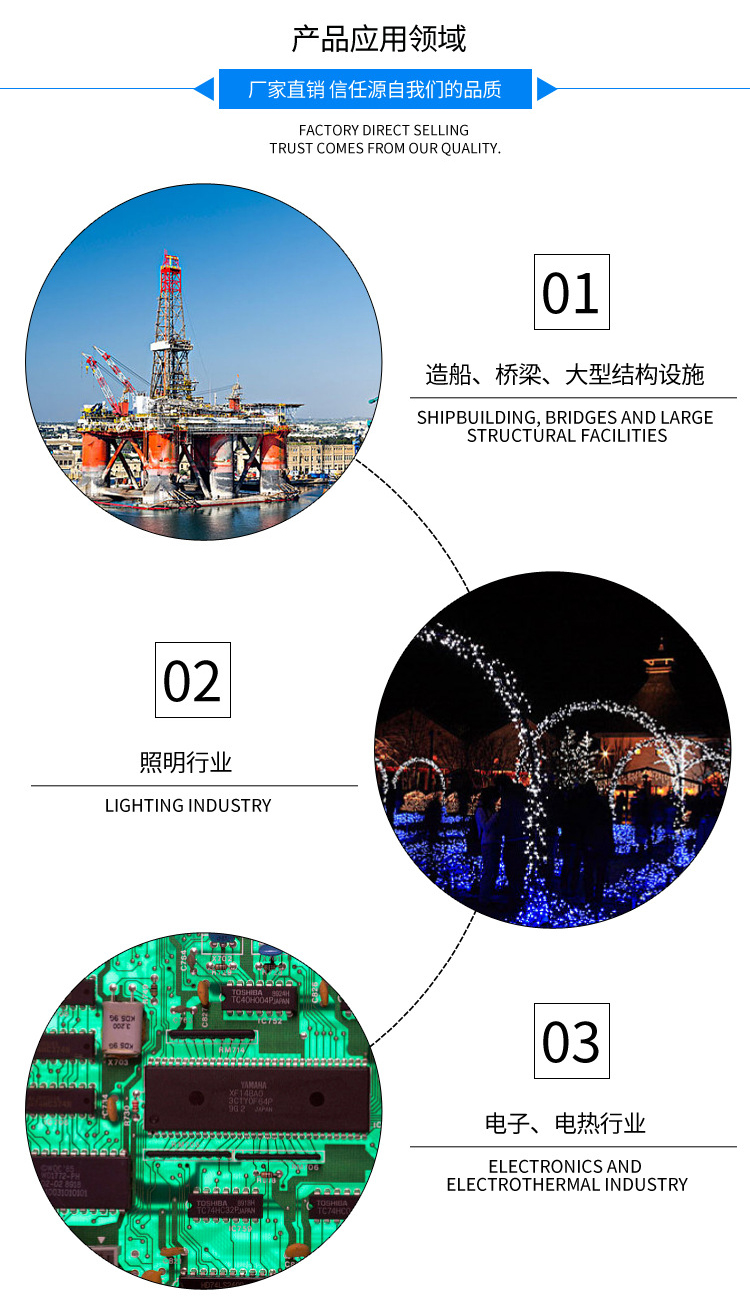

Widely used in coal-fired power plants, iron and steel, smelting, machinery, coal, mining, chemical, cement, port and terminal enterprises, coal transportation, conveying system, powder milling system, ash discharge, dust removal system and other large wear and tear mechanical equipment , Can provide different types of products according to different needs

Material Project | Alumina AL203 | Silicon carbide sic | Silicon nitride sin | Silicon nitride sin | ||||

| Color | Ivory | black | black | Milky white, gray black | ||||

| Content(%) | 99.5 | …… | …… | …… | ||||

| Main features |

|

|

|

| ||||

| The main purpose |

|

|

|

| ||||

| Density | Kg/m³ | 3.9*10 | 3.16*10 | 3.3*10 | 6.0*10 | |||

Mechanical behavior | Vickers hardness | Gpa | 16.0 | 23.0 | 14.0 | 13.2 | 12.7 | |

| Flexural strength | Mpa | 360 | 450 | 1020 | 1000 | 1470 | ||

| Compressive strength | Mpa | 2350 | …… | …… | …… | …… | ||

| Fracture toughness | Mpa | 4 | 2-3 | 7 | 4-5 | 4-5 | ||

Thermal performance | Linear expansion coefficient | 40-400℃ | ×10-5/℃ | 7.2 | 3.7 | 2.8 | 10.5 | 10.8 |

| 40-800℃ | 8.0 | 4.4 | 3.3 | 11.0 | 11.3 | |||

| Thermal conductivity | W/(m·k) | 32 | 200 | 27 | 3 | 3 | ||

| Specific heat | J/(kg·k) | 0.78*10 | 0.67*10 | 0.65*10 | 0.46*10 | 0.46*10 | ||

| Thermal shock resistance (in water) | ℃ | 250 | …… | >800 | 300 | 350 | ||

| Electrical performance | Dielectric strength | V/m | 15*105 | …… | 13*105 | 11*105 | …… | |

| Volume resistance(20℃) | Ω·cm | >1014 | 108 | 1014 | 1013 | …… | ||

| Dielectric constant | …… | 9.6 | …… | 9.9 | 33 | …… | ||

| Loss factor | ×10-4 | 10 | …… | …… | 520 | …… | ||

• Size and thermal stability

• High performance features

• Hydrolysis resistance

• Self-lubricating performance

• Extended service life

The ceramic positioning pin has extremely strong corrosion resistance, and can also be used in strong acid, strong alkali and sea water. At 1100 ℃, the strength and hardness are almost unchanged. Can also be used in non-magnetic and magnetic fields. Electrical insulation. The density is 3.25---3.28g/cm3, light weight, about 60% lighter than the steel ball, which greatly reduces the centrifugal force on the channel when the bearing rotates at high speed and reduces wear. High rigidity, high strength, its hardness is twice as high as bearing steel, and the elastic modulus is about 1/3 higher. The coefficient of linear expansion is 3.2×10-6/K, which is almost 1/4 of the bearing steel, and can withstand the rapid changes in temperature.

With the development of science and technology and the improvement of manufacturing technology, new varieties continue to appear, and they will be used more and more in the fields of modern industry and modern science.

Packed in carton

1. Are you a businessman or a manufacturer?

We are a company, we have our own factory

2. How long is your delivery time?

Negotiable

3. Can the product be customized?

Can be customized

4. What is the product packaging?

Carton or according to customer requirements

|