| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Welding Ceramics |

|---|---|

| Brand Name: | Weite ceramics |

| Certification: | ISO9001 |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1000piece |

| Price: | Negotiate |

| Supply Ability: | 100000 per month |

| Packaging Details: | carton |

| Material: | Silicon nitride positioning pin |

| colour: | Dark gray\black |

| Features: | High thermal shock resistance |

| Relative density: | 99% |

| Hardness (HV): | 14-16 |

| Fracture toughness: | 6-7(MPa•m1/2) |

| Thermal shock resistance ΔT℃: | 1300 |

| Application: | Aerospace and military industry |

| Company Info. |

| Yixing Weite Chinaware Co., Ltd |

| View Contact Details |

| Product List |

Silicon Nitride Welding Ceramic Positioning Pin

Silicon nitride ceramics have high strength, especially high-purity

silicon nitride, which is one of the hardest substances in the

world.

Very strong corrosion resistance, can be used in strong acids and alkalis, soluble in hydrofluoric acid but does not react with other organic acids

Performance:

Uses of shaped ceramic positioning pins: automobiles, clutches,

engines, universal joints, axles, motorcycles, crankshafts,

connecting rods, loaders, excavators, power tools, pneumatic tools,

construction machinery, etc.

Classification of special-shaped ceramic positioning pins: fixed

positioning pins, replaceable positioning pins, tapered positioning

pins, trimmed positioning pins, standard diamond shaped positioning

pins.

Ceramic positioning pin material: zirconia and alumina, silicon

nitride ceramic material.

We can customize various types of non-standard special-shaped ceramic positioning pins and special-purpose special-shaped ceramic positioning pins according to customers' use environment, use requirements and required material properties.

Material Project | Alumina AL203 | Silicon carbide sic | Silicon nitride sin | Silicon nitride sin | ||||

| Color | Ivory | black | black | Milky white, gray black | ||||

| Content(%) | 99.5 | …… | …… | …… | ||||

| Main features |

|

|

|

| ||||

| The main purpose |

|

|

|

| ||||

| Density | Kg/m³ | 3.9*10 | 3.16*10 | 3.3*10 | 6.0*10 | |||

Mechanical behavior | Vickers hardness | Gpa | 16.0 | 23.0 | 14.0 | 13.2 | 12.7 | |

| Flexural strength | Mpa | 360 | 450 | 1020 | 1000 | 1470 | ||

| Compressive strength | Mpa | 2350 | …… | …… | …… | …… | ||

| Fracture toughness | Mpa | 4 | 2-3 | 7 | 4-5 | 4-5 | ||

Thermal performance | Linear expansion coefficient | 40-400℃ | ×10-5/℃ | 7.2 | 3.7 | 2.8 | 10.5 | 10.8 |

| 40-800℃ | 8.0 | 4.4 | 3.3 | 11.0 | 11.3 | |||

| Thermal conductivity | W/(m·k) | 32 | 200 | 27 | 3 | 3 | ||

| Specific heat | J/(kg·k) | 0.78*10 | 0.67*10 | 0.65*10 | 0.46*10 | 0.46*10 | ||

| Thermal shock resistance (in water) | ℃ | 250 | …… | >800 | 300 | 350 | ||

| Electrical performance | Dielectric strength | V/m | 15*105 | …… | 13*105 | 11*105 | …… | |

| Volume resistance(20℃) | Ω·cm | >1014 | 108 | 1014 | 1013 | …… | ||

| Dielectric constant | …… | 9.6 | …… | 9.9 | 33 | …… | ||

| Loss factor | ×10-4 | 10 | …… | …… | 520 | …… | ||

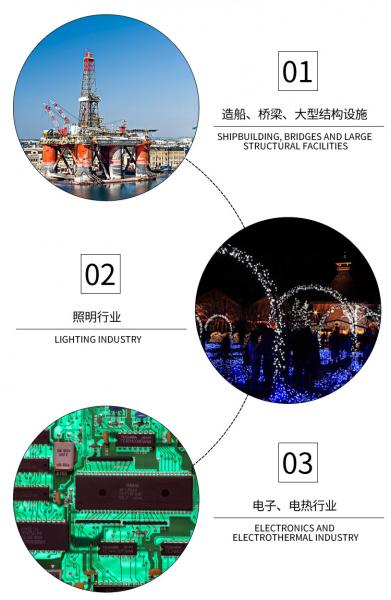

Ceramic positioning pins can be applied to accessories for special

purpose parts of high temperature resistance, corrosion resistance,

wear resistance, and high voltage resistance used in industries

such as electronics, machinery, chemical industry, metallurgy,

textiles, and power.

After the positioning pin is worn, it will produce a blocking

effect when loading and unloading, causing the positioning hole of

the part to be hooked. In order to ensure the accuracy of the

relative position between the two parts after the certificate is

installed, cylindrical pins or tapered pins are often used for

positioning, so the requirements for the pins and pin holes are

high. In order to facilitate the processing of pin holes and pins,

as far as possible, the pin holes are made as through holes as much

as poss

Special-shaped ceramic positioning pins have extremely strong corrosion resistance, and can also be used in strong acids, strong alkalis, and seawater. At 1100 ℃, the strength and hardness are almost unchanged. Can also be used in non-magnetic and magnetic fields.

Packed in carton

1. Are you a businessman or a manufacturer?

We are a company, we have our own factory

2. How long is your delivery time?

Negotiable

3. Can the product be customized?

Can be customized

4. What is the product packaging?

Carton or according to customer requirements

|

|