| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vacuum Drying Equipment |

|---|---|

| Brand Name: | YIGAN |

| Model Number: | FZG |

| Certification: | CE,GMP |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | negotiation |

| Delivery Time: | 20 working days after received your payment |

| Packaging Details: | Packed in film firstly, and then reinforced with wooden case for outer packing |

| product name: | vacuum dryer/vacuum drying equipment |

| features: | solvent recovery |

| drying type: | static |

| application: | indoor |

| tray number: | 48 trays |

| heating resource: | steam,electrical,oil |

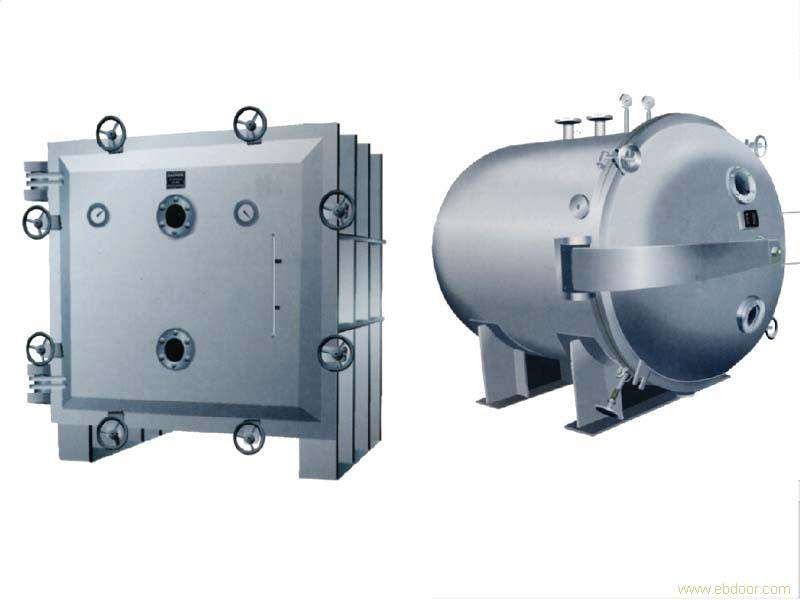

FZG Series Static Square Shape Vacuum Drying Equipment for Solvent Recovery

APPLICATION

FZG Series Static Square Shape Vacuum Drying Equipment for Solvent

Recovery is suitable for drying heat sensitive raw materials that can decompose

or polymerize or deteriorate at high temperature. It is widely used

in pharmaceutical, chemical, foodstuff and electronic industries.

FEATURES

1) The boiling point of raw material will be decreased under the

vacuum condition and make the evaporator increases the pushing

force of heat transfer.

2) The heat source can be low pressure steam or waste heat;

3) The loss of the heat during the evaporation is only a little.

4) The disinfection treatment can be carried out before drying and

there is no impurity material mixing during drying process. It is

in conformity with the requirement of GMP;

5) Static vacuum dryer will not damage the shape of raw materials.

WORKING PRINCIPLE

FZG Series Static Square Shape Vacuum Drying Equipment for Solvent

Recovery is to let the raw material to be dried at vacuum condition. It uses

vacuum pump to pump damp air out and make the working chamber form

vacuum status. Therefore, the drying speed of raw material is

improved and the energy is saved greatly. Notes: The solvent of raw

material can be collected by using a condenser. If the solvent is

water, the condenser is not required in order to save investment

cost.

Technical Parameters

| Model | FZG-10 | FZG-15 | FZG-20 |

| Size of baking tray (mm) | 460×640×45 | 460×640×45 | 460×640×45 |

| Quantity of baking trays | 20 | 32 | 48 |

Work pressure inside the pipe of baking support (MPa) | ≤0.784 | ≤0.784 | ≤0.784 |

operation temperature of baking support (℃) | 35-150 | 35-150 | 35-150 |

| vacuum degree inside the chamber when operation idle(MPa) | -0.1 | -0.1 | -0.1 |

Under -0.1Mpa and 110℃, water evaporation rate (kg/m2 ·hr) | 7.2 | 7.2 | 7.2 |

| vacuum pump with condenser pump | 2X-70A-5.5KW | 2X-70A-5.5KW | 2X-90A-7.5KW |

| vacuum pump without condenser | SZ-2-4KW | SZ-2-4KW | SZ-2-5.5KW |

| Weight of drying chamber(kg) | 1400 | 2100 | 3200 |

| Inter size of chamber(mm) | 1500×1060×1220 | 1500×1400x1220 | 1500×1800x1220 |

| Outer size of chamber(mm) | 1924×1720x1513 | 1513×1924x2060 | 1924×2500x1513 |

|