| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Storage Rack Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD170 |

| Certification: | CE,ISO,CO,FORM A,FORM E |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | USD 30000/set |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets for 75 working days |

| Delivery Time: | 75 working days |

| Packaging Details: | Plastic Film and Wooden Case |

| Thickness: | 2~3mm |

| Width: | 550mm |

| Machine Name: | Storage Rack Roll Forming Machine |

| Forming Speed: | Max. 15m/min |

| Roll Forming Station: | 20 Stations |

| Diameter of Shaft: | 75mm |

| Roller Material: | Cr12 |

| Steel Profile: | Heavy Duty Warehouse Supermarket Rack |

| Base Frame: | H-Beam Frame |

| Cutting Blade: | Cr12 with heat treatment |

Automatic Steel Profile Storage Rack Roll Forming Machine for Heavy

Duty Warehouse Pallet Shelves

Features & Purposes of Stroage Rack Roll Forming Machine

Our shelf roll forming machine is driven by gearbox, which can run

more stably, and adopt mould pressing and shearing to avoid hole

deformation and improve product quality. The products are widely

used in supermarkets, warehouses and other places.

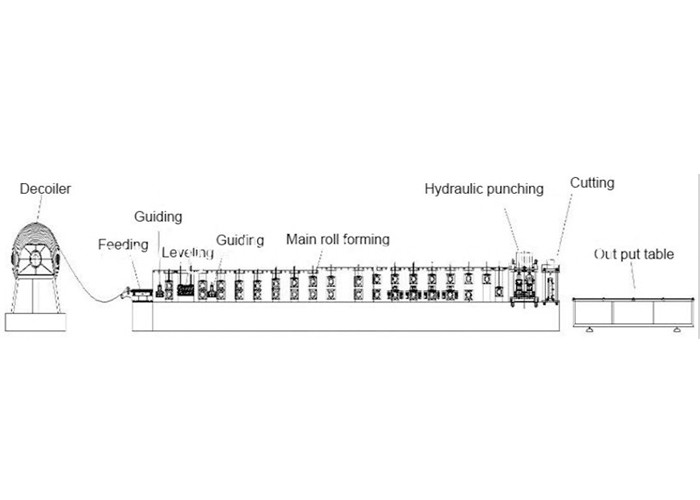

The storage rack roll forming machine consists of automatic

uncoiler, guide frame, leveling machine, punching device, forming

section, positioning cutting section, collection platform,

electrical control system, etc.

According to the market demand, we can design series or products

independently with years of experience in cold rolling forming

machine.

The structure we used in this machine has high working mechanical

properties. The roller is processed by numerical control and

quenched, and the hardness reaches HRC 58-62.

Its design width is variable, suitable for all sizes of products.

Customers only need to provide drawings and requirements.

It is convenient for customers to adjust product output and ensure

product straightening. It can avoid bending and twisting.

Components for punching storage rack upright roll forming machine

| Name | Quantity | Units | |

| Decoiler | 1 | Set | |

| Main Machine | Feeding device | 1 | Set |

| Roll forming system | 1 | Set | |

| Cut Equipment | 1 | Set | |

| Hydraulic system | 1 | Set | |

| Electric control system | 1 | Set | |

| Supporter/Automatic Stacker | 1 | Set | |

| 1. Profile | .Thickness:2.0mm |

| 2. Process flow | Decoiling---feeding---leveling---punching---forming---cutting---production |

| 3. Manual decoiler | 1) Material coil inner diameter: 450mm-550mm |

| 4. Punching machine | 60t Automatic punch holes(with one set of mold) |

| 5. Forming system | 1) Number of forming steps:2 steps feeding rollers,4 steps leveling

rollers, 12steps forming rollers, |

| 6. Cutting system | 1) Material: blade and mold material: Cr12 steel with quenched

treated 60-62℃ |

| 7. Control system | 1) Screen: Delta screen from Taiwan |

| 8. Hydraulic | 1) Advanced hydraulic system from Taiwan |

| 9. Spare Parts | 1) Easy damaged parts: conk 2 pcs, fuse-link 4 pcs |

| 1 | Suitable material | Color steel sheet , galvanized steel sheet |

| 2 | Main motor power | 15 KW with Cycloidal reducer |

| 3 | Hydraulic station power | 11KW |

| 4 | Hydraulic oil | 45# |

| 6 | Thickness | 1.5mm~5mm |

| 7 | Diameter | Φ95mm |

| 8 | Electric tension | 380V 3phase 50HZ |

| 9 | Material of roller | High grade 45# forged steel |

| 10 | Rolling galvanization thickness | 0.05mm |

| 11 | Processing speed | 10-15m/min |

| 12 | Processing precision within | 10m+/-1.00mm |

| 13 | Material of cutting blade | Cr12 quenched |

Shelf Roll Forming Machine Woring Process

Decoiler ----- Leveling (Straightening) ----- Roll Forming -----

Punching ----- Cutting ----- Unloading

Or

Decoiler ----- Leveling (Straightening) ----- Punching ----- Roll

Forming ----- Cutting ----- Unloading

|