| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roof Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD160 |

| Certification: | CO,CE,FORM A, FORM E |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 8000/set |

| Payment Terms: | T/T |

| Supply Ability: | 50 sets/month |

| Delivery Time: | 30 days |

| Packaging Details: | Plastic Film and Wooden Case |

| Material: | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

| Usage: | Roof Panel, Color Steel Tile |

| Industry: | Tile Making Machinery |

| Speed: | Max. 15m/min |

| Thickness: | Max. 1.2mm |

| Roller Material: | Cr12 |

| Shaft Material: | 40Cr |

| Diameter of Shaft: | 70mm |

| Hydraulic Station Power: | 7.5KW |

| Driven Way: | Chain |

| Main Motor Power: | 5KW |

| Roller Station: | 18 Stations |

Automatic Galvanized Corrugated Metal Sheet Roofing Wall Panel Roll Forming Machine

Roof Panel Roll Forming Machine Detailed Description

1. 1.5T manual decoiler

Features: Mandrel and basement are the two components of the decoiler, the mandrel is shrinking expanding by mechanical device manually, after fix coil to mandrel, then put back the coil with mandrel together to basement.

Power: None;

Power of the open and closure of segments: Mechanical;

Power of rotation of segment: Pull by forming system;

Number of segment: 4pcs;

Range of segment expansion: 460 ~ 520mm;

Height of center of the mandrel: 0.65m;

Feeding speed: depend on the roll forming machine speed

2. Main roll forming Device

Rollers:we use Cr12 material

Shaft: manufactured with 45# high grade steel or 40Cr by CNC machine tools;

Supporting frame: steel wallboard to guide the forming station bearing basement;

Frame: section steel be welded according to the profile forming requirement;

Center height: it is more higher than normal structure, suitable for operation.

Working Process Flow of Roll Forming Machinery

Decoiler→ Feeding → Roll forming → Hydraulic cutting → Output table

Roll Forming Machine Technical Parameter Requirements

| Main moter power | 4 kw |

| Hydraulic station power | 3 kw |

| Shearing die | Gr12 |

| Sprocket | P-25.4 |

| Transmission mode | Chain |

| The bearing capacity of manual decoiler | 5 tons |

| Sprocket chain specifications | 0.6 inch |

| Roller station | 10-15 rows |

| Main frame structure | 350H steel |

| Diameter of principal axis | 75mm |

| Material of roller | 45#steel hard chrome Hardness HR55°—57° Solid shaft |

| Processing speed | 10-15m/min |

| Thickness | 0.2-0.7mm |

| Feeding material width | 600mm-1250mm |

| 1. | Dimension | 5800*1600*1400mm |

| 2. | Weight | 7000KGS |

| 3. | Motor Power | 7.5KW*2 sets |

| 4. | Hydraulic Power | 2.2KW |

| 5. | Voltage | 380V/50HZ/3PH (according to your requirements) |

| 6. | Forming Stations | 13 |

| 7. | Forming Speed | 8-14m/min |

| 8. | Effective Width | 300mm,400mm,500mm |

| 9. | Material of Width | 470mm,575mm,680mm |

| 10. | Material of AL-Mg-Mn,Galvanized Sheet Thickness | 0.4-1.0mm |

| 11. | Material of Colored Prepainted Sheet Thickness | 0.5-0.8mm |

| 12. | Material for All Roller | high grade no.45 forged steel,plated hard chrome and polished the rollers |

Roof Panel Roll Forming Machine Components

| Item | Name | Qty |

| 1 | Manual Decoiler | 1 set |

| 2 | Feeding platform with hand cutting system | 1 set |

| 3 | Main forming system | 1 set |

| 4 | Hydraulic cutting system | 1 set |

| 5 | Hydraulic pump station | 1 set |

| 6 | Electrical motor | 1 set |

| 7 | PLC control system | 1 set |

| 8 | Touch screen operation | 1 set |

| 9 | Finished products receive table | 1 set |

| 10 | Safety shield(optional) | 1 set |

Technical Parameters of Roof Panel Roll Forming Machinery

| NO | Item | Description |

| 1 | Product' sizes | According to customer's request |

| 2 | Processing material | GI |

| 3 | Processing thickness | 0.6-1.2mm |

| 4 | Main motor power | 7.5kw |

| 5 | Power of hydraulic station | 7.5kw |

| 6 | Quantity of roller stations | 20 |

| 7 | Production speed | Approximate 15-25 m/min |

| 8 | Diameter of shafts | Φ80mm |

| 9 | Material of rollers | Cr12 steel with vacuum heat treatment HRC57°-60° |

| 10 | Material of shafts | 45# steel quenched and tempered |

| 11 | Material of cutting blades | Cr12 mould steel with quenched treatment |

| 12 | Size of machine | Approximate 7500mm(L)×160mm(W)×1800mm(H) |

| 13 | Theoretical weight | Approximate 7000KGS |

| 14 | Driven method | Chain transmission |

| 15 | Brand of PLC | Yaskawa |

| 16 | Cut mode | Hydraulic profile cutting |

| 17 | Power supply | 380V 50HZ 3Phases or at buyer's requirement |

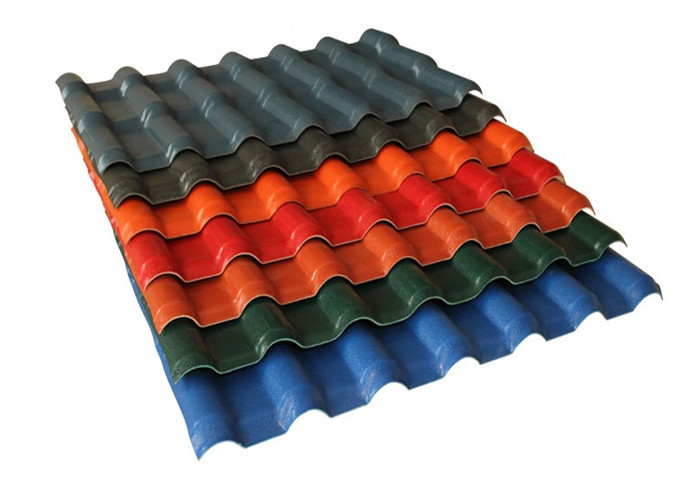

All Kinds of Color Steel Tile

|