| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Shutter Door Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD130 |

| Certification: | CO,CE,FORM A, FORM E |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 8000/set |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets/month |

| Delivery Time: | 45 days |

| Packaging Details: | Plastic Film and Wooden Case |

| Driven Way: | Gearbox or Chain driven |

| Speed of Roll Forming: | 15~30 m/min |

| Machine Name: | Shutter Door Roll Forming Machine |

| Roller Stations: | 12 Passes |

| After-sales Service Provided: | Online support, Free spare parts, Engineers available to service machinery overseas |

| Roller Material: | Cr12 |

| Shaft Material: | 40Cr |

| Thickness: | 0.4~1.5mm |

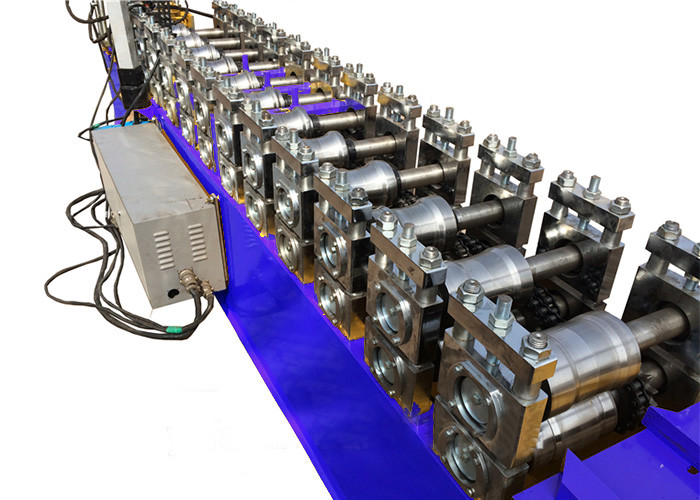

Automatic Galvanized Metal Door Machine Roller Shutter Slat Steel Roll Forming Machinery

CO-EFFORT Advantages

1. Our factory has advanced technology, experienced engineers, professional foreign trade team.

2. Standard design for you to choose from, you can also customize

the machine according to your drawings.

3. Adopt the latest design and structure, make the machine durable.

4. Short delivery time, free training, free technical support for

life.

5. Further study the local market to help customers grow and

develop.

Roll Forming Machine Technical Requirements

| Suitable Material | Material | GI, PPGI, PPGL |

| Width | 130 mm | |

| Thickness | 1 mm | |

| Material of rollers | High grade 45# forged steel, surface hard chromium plating | |

| Rows of rollers | 12 stations | |

| Material of shafts | High grade 45# forged steel | |

| Diameter of shafts | 50 mm | |

| Material of cutting blade | Cr12 Heat Treatment | |

| Speed | 10-15 m/min | |

| Side plate thickness | 16 mm | |

| Chain size | 1 inch (you can choose gearbox driven) | |

| Weight | 2 tons | |

| Length measurement | Encoder | |

Electric Elements Brand

| No | Items | Brand | Remark |

| 1 | PLC | Mitsubishi | |

| 2 | HMI | WEINVIEW | |

| 3 | Electric Elements | Schneider | |

| 4 | Bearing | NSK/SKF | |

| 5 | Main Motor | China Brand |

Roll Forming Machine configuration and performance

Composition and Production Process

De-coiler →→Roll Forming→ Cutting→ Unloading

Technical Parameters

| No | Items | Technical Parameters | |

| 1 | De-coiler | Width of Strip | ≤150mm; |

| Thickness of Strip | ≤1mm; | ||

| Inner Diameter of Coil | ф480-520 mm(according to customer’s requirements) | ||

| Outer Diameter of Coil | φ1300mm;Loading Weight:≤2T | ||

| Expand Way | Manual | ||

| 2 | Roll Forming | ||

| Forming Station | 12 Stations | ||

| Driven | Chain | ||

| Pitches of Passes | 300mm | ||

| Max. Width of Strip | 150mm | ||

| Max. Thickness of Strip | 1mm | ||

| Roller Shafts | Φ50mm ,45# (quenching and tempering) | ||

| Roller Material | Cr12,Hardness HRC58-60° | ||

| Main Motor Power | 5.5KW | ||

| 3 | Cutting Device | ||

| Cutting Way | Hydraulic | ||

| Cutting Accuracy | Length Encoder Control Full Length (+2MM) | ||

| Material of Cutting Blade | CR12MOV | ||

| 4 | Unloading | ||

| Manual blanking structure | Rollers | ||

| 5 | Control System | ||

Usage and Characteristics 1. The whole line is controlled by PLC, LCD touch screen and man-machine interface. Realize the interaction between people and PLC. Operators can automatically run (programmable control) and monitor the control process through the set program. Operators can control the production line and modify the control parameters. They can also real-time monitor the operation status of equipment, operation parameters and fault indication. The length of the part can be adjusted by setting the number of the parts. Real-time monitoring equipment operation status and fault indication. 2. There are two modes of operation: manual and automatic. With manual and automatic switching function: in the manual state, can stand-alone operation, easy maintenance; in the automatic state, the full range of production run, the order to start; full line with emergency stop button, easy to deal with emergencies, to ensure that equipment and operators Safety. 3. There is a manual operation panel next to the operator to facilitate the operation of the workers. | |||

| 1 | Name of Machine | Rolling Door Roll Forming Machine/Roll-up Door Slat Making Machine/Roller Shutter Door Strip Production Line |

| 2 | Equipment operation | PLC Control |

| 3 | Total power | 10KW |

| 4 | Effective Width | 312mm |

| 5 | Roller Station | 12 Stations |

| 6 | O.D. of Rollers | 25-30mm |

| 7 | Productivity | 15-30m/min |

| 8 | Weight | around 3.5T |

| 9 | Voltage | 380V50Hz 3Phases (According to your requirements) |

| 10 | Thickness of Steel Coil | 0.4-1.5mm |

| 11 | Cutting Device | Cutting by flying saw |

| 12 | Usage | warehouse , supermarket , garage,etc |

Shutter Door Roll Forming Machine Details

|