| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Stainless Steel Screen Printing Mesh |

|---|---|

| Brand Name: | BJPFM |

| Model Number: | PFM - Stainless Steel Printing Mesh |

| Certification: | SGS |

| Place of Origin: | China |

| MOQ: | 1 Square Meter |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 8000 Square Meter/Square Meters per Week |

| Delivery Time: | 7-15 days after payment |

| Packaging Details: | Generally, kraft paper inside and air bubble film outside, then be put into a wooden case. Or be packaged according to your requirement. |

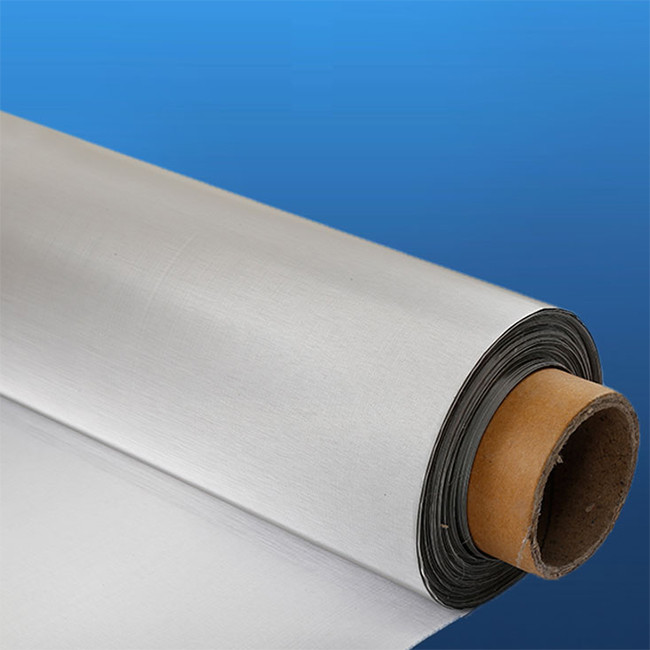

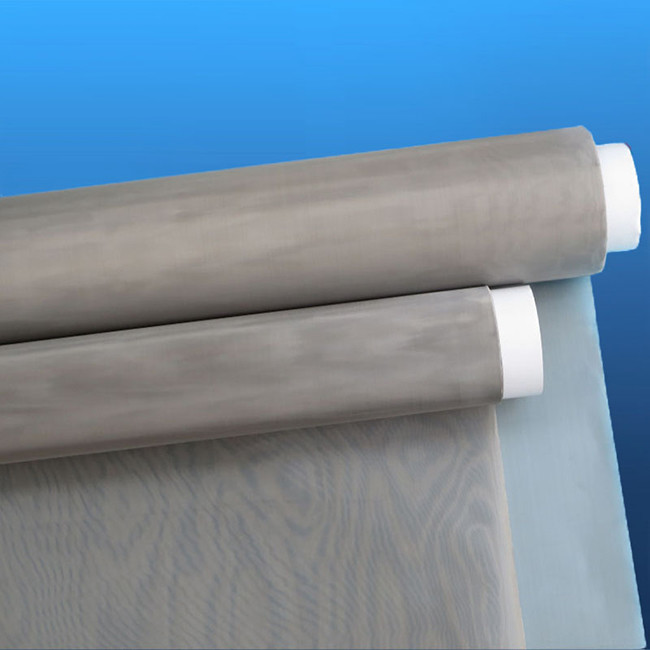

| Product name: | Plain Woven Ultra Fine Stainless Steel Wire Silk Screen Printing Mesh |

| Type: | Weave Wire Mesh Test Sieve |

| Material: | Stainless Steel 304N |

| Elasticity: | Low |

| Weave Type: | Plain woven |

| Mesh Count: | 40 - 500 mesh/inch |

| Aperture: | 41-268 micron |

| Width: | MAX 1.27m |

| Length: | 30m/roll or as your request |

| Company Info. |

| Beijing PFM Screen Co., Ltd. |

| View Contact Details |

| Product List |

Stainless Steel Wire Silk Screen Printing Mesh uses a wire imported from Japan, which has 2 times higher tensile strength compared to the common domestic wires and an extremely low elongation rate of 3-5%. This screen printing mesh shows extraordinary performance in printing that requires fine patterns and dimensional accuracy.

· High tension: Much higher tension than common polyester mesh and smooth tension;

· Super precision: Uniform wire diameter and aperture with an extremely low difference;

· Low elongation: Very small elongation of wire mesh at high tension;

· High stability: The wire mesh will not lose elasticity at extreme tension;

· High corrosion resistance: The excellent corrosion resistance of stainless steel wire exceeds polyester fiber;

· Non-electrostatic: To avoid the effects of non-electrostatic for print and ensure the safety of printing;

· Good heat-melting resistance: Special features of stainless wire mesh. Suitable for heat-melting ink;

· Good solvent resistance: To avoid the effects of any solvents to wire mesh and to ensure the safety of the print screen.

| Specification | Mesh/ inch | Wire Dia (μm) | Open area Ratio(%) | Apereture (μm) | Apereture (μm) | Calendered Thickness (μm) | Theoretical lnk(cm^/m^) |

| 40*40*160 | 40 | 160 | 56 | 475 | 300-320 | As order | 179.1 |

| 60*60*120 | 60 | 120 | 51.3 | 303 | 230-245 | As order | 123.2 |

| 80*80*120 | 80 | 120 | 39 | 198 | 235-245 | As order | 92.9 |

| 80*80*90 | 80 | 90 | 52 | 228 | 175-180 | As order | 103 |

| 80*8*50 | 80 | 50 | 71 | 268 | 95-100 | As order | 78 |

| 100*100*100 | 100 | 100 | 36.8 | 154 | 195-205 | As order | 77.2 |

| 120*120*80 | 120 | 80 | 39 | 132 | 155-165 | As order | 65.8 |

| 150*150*60 | 150 | 60 | 41.7 | 109 | 115-124 | As order | 50 |

| 165*165*35 | 165 | 35 | 60 | 119 | 70-75 | As order | 48 |

| 165*165*45 | 165 | 45 | 50.1 | 109 | 88-93 | As order | 45.1 |

| 165*165*50 | 165 | 50 | 45.6 | 104 | 97-105 | As order | 45.6 |

| 180*180*45 | 180 | 45 | 46.4 | 96 | 88-93 | As order | 41.5 |

| 180*180*50 | 180 | 50 | 42 | 91 | 98-104 | As order | 41.7 |

| 200*200*40 | 200 | 40 | 46.9 | 87 | 82-84 | As order | 43 |

| 200*200*50 | 200 | 50 | 37 | 77 | 98-103 | As order | 42 |

| 230*230*35 | 230 | 35 | 46.7 | 75 | 72-76 | 50-67 | 37 |

| 250*250*40 | 250 | 40 | 36.8 | 62 | 82-86 | 50-80 | 34 |

| 250*250*30 | 250 | 30 | 49.7 | 72 | 64-68 | 40-58 | 30 |

| 250*250*35 | 250 | 35 | 43 | 67 | 76-78 | 57-70 | 32 |

| 325*325*30 | 325 | 30 | 38 | 48 | 66-68 | 45-60 | 24 |

| 325*325*23 | 325 | 23 | 49.8 | 55 | 49-53 | 37-41 | 25.4 |

| 350*350*35 | 350 | 25 | 43 | 48 | 52-54 | 41-50 | 18.7 |

| 400*400*23 | 400 | 23 | 40.7 | 41 | 50-54 | 35-48 | 19 |

| 400*400*18 | 400 | 18 | 51.3 | 46 | 36-40 | 28-30 | 20 |

| 500*500*18 | 500 | 18 | 41.7 | 33 | 36-40 | 23-29 | 15.3 |

Stainless steel screen printing mesh is widely used for screen printing in screen printing in the Printed circuit board, Solar Battery, Liquid Crystal Display, Chip Electrical Components, Flat Panel Display, Glass industries. Stainless steel screen printing mesh is widely used for screen printing in screen printing in the Printed circuit board, Solar Battery, Liquid Crystal Display, Chip Electrical Components, Flat Panel Display, Glass industries.

· Printed circuit boards;

· Multilayers;

· Thick film;

· Soldering pastes for SMT;

· Keypads;

· Glass printing;

· Ceramic printing;

|