| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

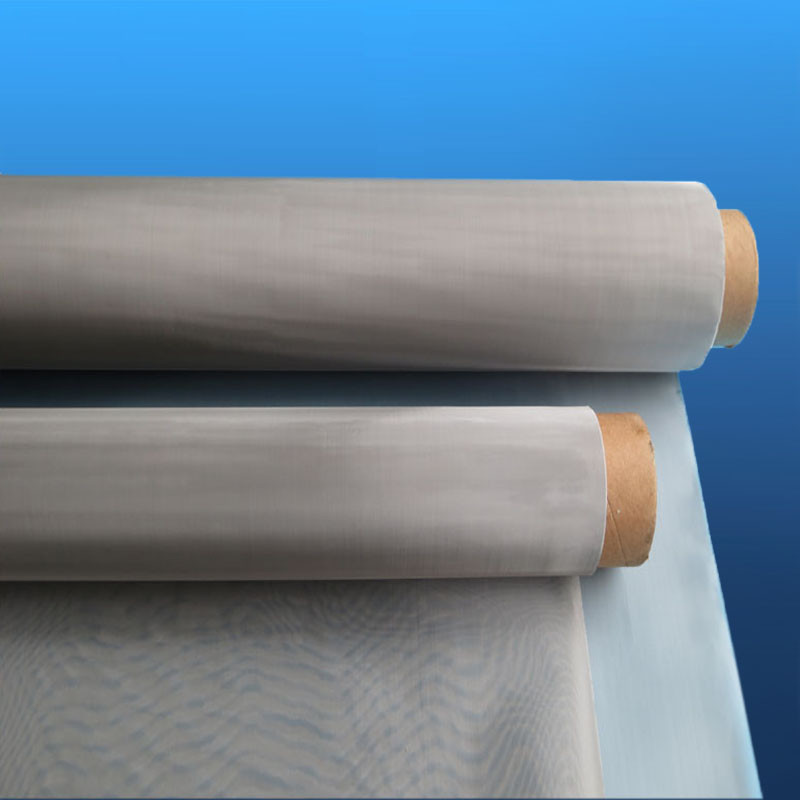

| Categories | Stainless Steel Screen Printing Mesh |

|---|---|

| Brand Name: | BJPFM |

| Model Number: | PFM - Stainless Steel Screen Printing Mesh |

| Certification: | SGS |

| Place of Origin: | China |

| MOQ: | 1 Square Meters |

| Price: | Through consultation |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000 Square Meter/Square Meters per Month |

| Delivery Time: | 7-10 work days |

| Packaging Details: | Moistureproof paper inside ,wooden cases outside and the plastic cloth filled in the middle |

| Material: | Ultra Fine Stainless Steel 304 304N 316 316L, etc |

| Weave type: | Plain |

| Wire diameter: | 0.018-0.02mm |

| Thickness: | 0.05 to 0.3mm |

| Mesh count: | 3-400mesh |

| Mesh Opening: | 0.022 to 23.37mm |

| Width: | 0.6-1.5m |

| Application: | Screen Printing Industry |

| Length: | 30m/roll 50m/roll or as your request |

| Feature: | Heat Resistance, High Tension Low Elongation, Corrosion Resisting, Long Life |

| Company Info. |

| Beijing PFM Screen Co., Ltd. |

| View Contact Details |

| Product List |

Material: Stainless Steel 304 304N 316 316L, etc;

Weave: Plain weave

Wire diameter: 0.018-0.02mm

Mesh/inch: 3-400mesh

Aperture: 0.022 to 23.37mm

Thickness: 0.05 to 0.3mm

Hole shape: square

Open area: 39.4%

Length: 30m/roll 50m/roll or as your request

Width: 0.6-1.5m

High tension. Much higher tension than common polyester mesh and this property is very stable;0

Super Precision: Uniform wire diameter and aperture with an extremely low difference;

Low Precision: Very small elongation of wire mesh at high tension;

High Flexibility: The wire mesh will not lose elasticity at extreme tension;

High Corrosion Resistance: The excellent corrosion resistance of stainless steel wire exceeds polyester fiber;

Non-electrostatic: To avoid the effects of non-electrostatic for printing and ensure the safety of printing;

Good Heat-melting Resistance: Special features of stainless steel wire mesh.Suitable for heat-melting ink;

Good Solvent Resistance: To avoid the effects of any solvents to wire mesh and to ensure the safety of printing.

| Mesh/Inch | Wire Diameter (μm) | Aperture(μm) | Open Area (%) | Thickness(μm) | Theoretical Ink (cm3/m2) |

| 40 | 160 | 475 | 56.0 | 300-320 | 179.1 |

| 60 | 120 | 303 | 51.3 | 230-245 | 123.21 |

| 80 | 50 | 268 | 71.0 | 95-100 | 78.0 |

| 80 | 90 | 228 | 52.0 | 175-180 | 103.0 |

| 80 | 120 | 198 | 39.0 | 235-245 | 92.9 |

| 100 | 100 | 154 | 36.8 | 195-205 | 77.2 |

| 120 | 80 | 132 | 39.0 | 155-165 | 65.8 |

| 150 | 60 | 109 | 41.7 | 115-124 | 50.0 |

| 165 | 35 | 119 | 60.0 | 70-75 | 48.0 |

| 165 | 45 | 109 | 50.1 | 88-93 | 45.1 |

| 165 | 50 | 104 | 45.6 | 97-105 | 45.6 |

| 180 | 45 | 96 | 46.4 | 88-93 | 41.5 |

| 180 | 50 |

|