| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Titanium Precision Parts |

|---|---|

| Brand Name: | MH |

| Model Number: | MH0805-2 |

| Certification: | ISO9001:2008 |

| Place of Origin: | Shaanxi, China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T, Paypal, Wechat, Alipay, Western Union |

| Supply Ability: | 200000pcs per month |

| Delivery Time: | 15-25workdays |

| Packaging Details: | poly-bag with doule carton or customized wooden box |

| Type: | High precision Ti-parts |

| Material: | Titanium, Titanium alloy |

| Surface treatment: | Plating, Polishing, Sandblasting, and Original |

| Process: | CNC machining, Acid and alkali washing, Hot forging, Wire - cutting |

| Application: | Racing, Industry, Medical, Outdoor |

| Tolerance: | 0.01 - 0.05mm |

| Size: | As drawing |

| Color: | All kind of Anodizing color |

| Advantage: | Light weight, High strength, Anti - Corrosion |

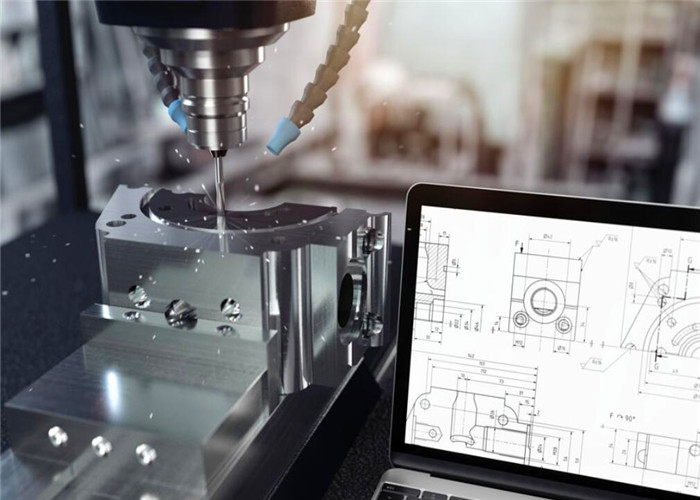

Custom Titanium Precision Parts CNC 5 Axis Machined TI6AL4V Racing Car Parts

Product description:

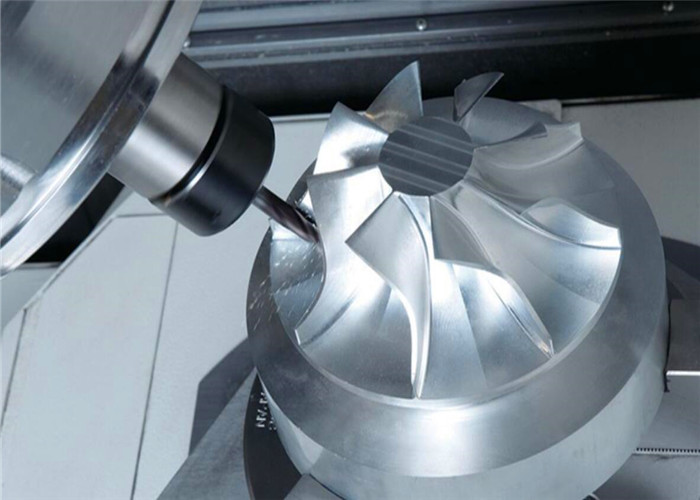

5-axis machining has featured in high efficiency and high precision, and the workpiece can be finished by only clamping in one time.

| Condition | Certification | Standard | Tolerance | Process | Micro Machining or Not | Standard or Non-Standard | Services | Specification |

| New | ISO2008:9001 | DIN, ASTM, GB, JIS | 0.01mm | Polishing Grinding Machine | Micro Machining | Non-Standard | OEM / ODM | custom |

It is suitable for the processing of modern molds such as auto parts and aircraft structural parts. 5-axis machining is not only used in civil industry but also widely used in aerospace, military, scientific research, precision instruments, high-precision medical device industry.

It is a high-tech method that makes impossible into possible, and all spatial surfaces or unusual shape machining can be done.

It can not only complete the processing tasks of complex parts but also can quickly improve the processing efficiency and shorten the processing flow.

Advantage:

The use of CNC precision machining, compared to manual machining, offers improved accuracy, productivity, efficiency, and safety, due to reduced human interaction with the machinery.

CNC machines are able to run unmanned for extended periods of time

and in the event of an error, the CNC software automatically ceases

its operation and calls for a supervisor.

CNC production also allows for greater speed of production as parts

that would otherwise require multiple steps to manufacture can be

produced quickly by the automated equipment.

Why Titanium?

Titanium itself is silver, which is polished and treated to make the surface more shiny.

High strength, 40% lighter than other materials, Processing pass the strict CNC machining and treatment to ensure 100% High-level performance and precision.

High tensile strength, heat resistance, elongation of 10.2%.

Lighter, faster, stronger, safer, and more fuel efficient, which is why titanium was chosen!

|