| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cement Grinding Balls |

|---|---|

| Brand Name: | DRAGON BALLS |

| Model Number: | 45# 60Mn B2 B3 Low Cr High Cr Medium Cr |

| Certification: | CE,ISO |

| Place of Origin: | CHINA |

| MOQ: | 1 ton |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 3000 tons / Month |

| Delivery Time: | 3-7 work days/ 25 tons |

| Packaging Details: | Container bags ,steel drums |

| Technology: | Forging,hot rolling,casting |

| Usage: | Mining,Cement plant,Power Station |

| Advantage: | High Wear Resistant,High output and low price |

| Material: | Steel Iron ,Round Steel |

| Tolerance: | +-1mm,+-2mm |

| Hardness: | According to the material and customer requirements |

| Package: | Container bags ,Steel drums |

| Service: | After sale service |

| Company Info. |

| Jinan Dragon Steel Balls Co.,Ltd |

| View Contact Details |

| Product List |

High Cr Casting Steel Balls Cement Grinding Balls Dry Grinding Wet Grinding balls

1. Ball Mill Balls Forged ball, Hot Rolling ball,Grinding rods specifications:

① Chemical Composition

| Material | Chemical Composition | |||||||

| C | Si | Mn | Cr | P | S | Ni | Cu | |

| C45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | ≤0.25 | ≤0.035 | ≤0.035 | ≤0.25 | ≤0.25 |

| 60Mn | 0.55-0.65 | 0.17-0.37 | 0.7-1.0 | ≤0.25 | <0.04 | <0.04 | ≤0.3 | ≤0.25 |

| B2 | 0.72-0.85 | 0.17-0.37 | 0.7-1.0 | 0.4-0.6 | ≤0.025 | ≤0.025 | ≤0.02 | ≤0.02 |

| B3 | 0.58-0.66 | 1.3-1.9 | 0.65-0.8 | 0.7-0.9 | ≤0.025 | ≤0.025 | ≤0.02 | ≤0.02 |

② Hardness

Size | C45 | 60Mn | B2 | B3 |

| 20mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 30mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 40mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 50mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 60mm | 55-58 | 58-62 | 60-64 | 62-65 |

| 70mm | 53-56 | 58-62 | 60-64 | 61-63 |

| 80mm | 53-56 | 58-62 | 59-63 | 60-65 |

| 90mm | 50-55 | 58-62 | 57-61 | 60-65 |

| 100mm | 48-52 | 57-61 | 56-60 | 60-65 |

| 110mm | 48-52 | 57-61 | 55-60 | 58-64 |

| 120mm | 48-52 | 57-61 | 55-60 | 56-63 |

| 130mm | 48-52 | 57-61 | 55-60 | 56-63 |

| 140mm | 48-42 | 57-61 | 55-60 | 56-63 |

| 150mm | 48-52 | 57-61 | 55-60 | 56-63 |

③ Weight

| Size(mm) | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 |

| Weight(kg) | 0.033 | 0.111 | 0.261 | 0.512 | 0.883 | 1.402 | 2.092 | 2.98 | 1.087 | 5.44 | 7.062 | 9.008 | 11.25 | 13.83 |

④ Dragon balls specifications

Diameter (mm) | Diameter Tolerance (mm) | Approx Weight of per ball(kg) | Average numbers per ton |

| 20 | +1,-0.5 | 0.033 | 30303 |

| 30 | +2,-1 | 0.11 | 9090 |

| 40 | +2,-1 | 0.261 | 3831 |

| 50 | +2,-1 | 0.512 | 1961 |

| 60 | +2,-1 | 0.883 | 1132 |

| 70 | +3,-1.5 | 1.402 | 713 |

| 80 | +3,-1.5 | 2.092 | 478 |

| 90 | +3,-1.5 | 2.98 | 335 |

| 100 | +3,-1.5 | 1.087 | 244 |

| 110 | +3,-1.5 | 5.44 | 183 |

| 120 | +3,-1.5 | 7.062 | 141 |

⑤ Grinding rods size

| Diameter | 30mm-90mm |

| Length | 3.2 m-4.5 m |

2. Ball Mill Balls Cast balls, cylpebs Specifications:

① Chemical Composition

| Material | C | Si | Mn | Cr | P | S |

| Low Cr | 2.2-3.4 | ≤1.2 | 0.5-1.5 | 1.0-1.5 | ≤0.06 | ≤0.06 |

| Medium Cr | 2.0-3.2 | <1.0 | 0.5-2.5 | ≥5 | ≤0.06 | ≤0.06 |

| High Cr | 2.0-3.2 | <1.0 | 0.5-2.5 | ≥10 | ≤0.06 | ≤0.06 |

② Hardness

| Type | Low Cr | Medium Cr | High Cr |

| 20mm-150mm | 45-50 | 48-55 | 58-63 |

③ Dragon Balls Weight

| Size(mm) | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 |

| Weight(kg) | 0.033 | 0.111 | 0.261 | 0.512 | 0.883 | 1.402 | 2.092 | 2.98 | 1.087 | 5.44 | 7.062 | 9.008 | 11.25 | 13.83 |

④ Dragon balls specifications

Diameter (mm) | Diameter Tolerance (mm) | Approx Weight of per ball(kg) | Average numbers per ton |

| 20 | +1,-0.5 | 0.033 | 30303 |

| 30 | +2,-1 | 0.11 | 9090 |

| 40 | +2,-1 | 0.261 | 3831 |

| 50 | +2,-1 | 0.512 | 1961 |

| 60 | +2,-1 | 0.883 | 1132 |

| 70 | +3,-1.5 | 1.402 | 713 |

| 80 | +3,-1.5 | 2.092 | 478 |

| 90 | +3,-1.5 | 2.98 | 335 |

| 100 | +3,-1.5 | 1.087 | 244 |

| 110 | +3,-1.5 | 5.44 | 183 |

| 120 | +3,-1.5 | 7.062 | 141 |

⑤ Grinding cylpebs Size(mm)

6×6 | 8×8 | 10×10 | 15×15 | 12×18 | 20×35 | 22×30 |

25×25 | 25×30 | 25×35 | 30×35 | 30×40 | 35×40 | 35×45 |

⑥ Production Process

Cast Balls and cylpebs are melted in electric furnace and poured into moulds after scientific proportioning. High chromium balls and cylpebs are also processed by oil quenching.

⑦ The Abrasion of the cast balls when grinding the cement

| Material | Abrasion | Breakage | Size(mm) |

| Low Chrome Cast Ball | 85-105g Cast Balls /Ton Cement | <2% | 10-150mm |

| Medium Chrome Cast Ball | 50-80g Cast Balls /Ton Cement | <1.5% | 10-150mm |

| High Chrome Cast Ball | 35-60g Cast Balls/Ton Cement | <1% | 10-120mm |

| High Chrome Cylpebs | 35-60g Cylpebs/Ton Cement | <1.5% | 12×18-35×40 |

| Low Chrome Cylpebs | 65-95g Cylpebs/Ton Cement | <1% | 12×18-35×40 |

| Micro Cylpebs | 6×6 8×8 10×10 12×12 15×15 | ||

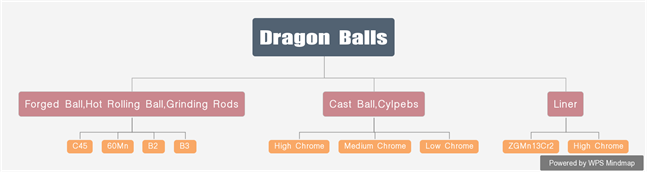

3. Cement Grinding Balls Classification:

4. The difference of the forged ball and cast ball

① Different production line

② Different raw material

③ Different chemical element

④ Different core hardness and core hardness

5. How to choose the material

① According to the different customer need and usage.

② According to the ball mill size, dry grinding or wet grinding. We can recommend you the most suitable products.

6. Ball Mill Balls Quality Control

① Factory Test

Grinding cylpebs test is an very important step. Real-time detection will be carried out in the production process. Cylpebs produced in each shift will be sampled in large quantities and tested for size, hardness, chemical composition, drop test, core pulling and impact value to ensure the quality of cylpebs

② The third party test

According to the customer different demand, cylpebs can be tested by any third party.

7. Packing

Cylpebs are usually packed in container bags and steel drums, it can also be customized according to different customer needs.

|