| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Forgings |

|---|---|

| Brand Name: | JIMA |

| Model Number: | AL |

| Certification: | ISO9001-2008,SGS,ROHS. |

| Place of Origin: | CHINA |

| MOQ: | 1PCS |

| Price: | Negotiations |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 10000 pcs /per month |

| Delivery Time: | 15~30days |

| Packaging Details: | Standard Export Wooden Pallet |

| Application: | Flange/Petrochemical machinery/ships |

| Name: | OEM 5056 Forged Aluminum Part For Flange Plate/Petrochemical Machinery/Ships/Cold Forging /Hot Forging |

| Standard: | JIS, DIN, BS, ASTM, SAE. |

| Alloy: | 5056 |

| Sample: | Can be Customized |

| Mold: | Can be Customized |

| Process: | Forging |

| Sueface Treatment: | Anodizing,Plating,Satin,Painting,Powder Coating,anodized Etc |

| Company Info. |

| JimaFor |

| Verified Supplier |

| View Contact Details |

| Product List |

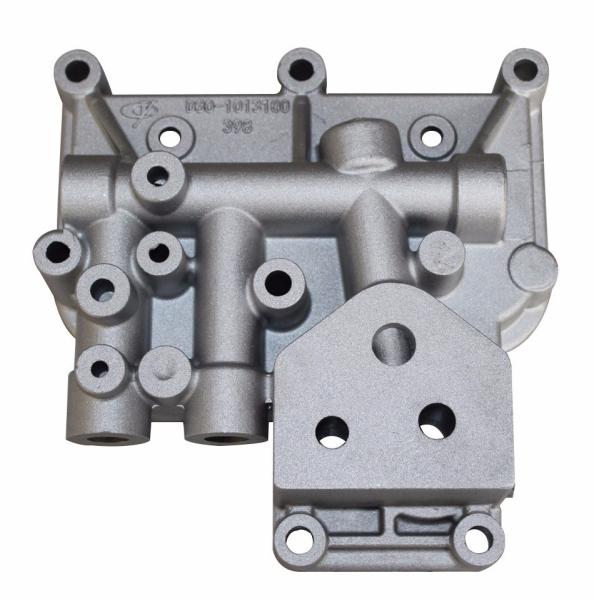

OEM 5056 Forged Aluminum Part for Flange Plate/Petrochemical Machinery/Ships/Cold Forging /Hot Forging

Product Details

| Material | Aluminum Alloy 5056 |

| Process | Forging+CNC+Heat Treatment |

| Surface Treatment | Transparent / Color Anodized;Hard Anodizing;Powder Coating; Sandblasting, Laser Carving, Silk Screening; Nickel-Plated, Chrome, Galvanized, Silver/Gold Plating; Black Oxide Coating; Polishing; etc... |

| Manufacture Ability | Depends on The Complexity Of Different Products And Quantities |

| Experience | Aluminum Machining Service for 12 Years |

| Packaging | Standard Export Wooden Pallets Another Request According to Your Need |

| MOQ | 1pcs |

| Sample | Can be Customized |

| Mold | Can be Customized |

| Lead Time | Mold for 15-20Days Process for 15-20Days |

| OEM | Can be Customized |

| Chemical Composition Limits | ||||||||||||

| Weight% | Al | Si | Fe | Cu | Mn | Cr | Mg | Mn+Cr | Ti | Zn | Others Each | Others Total |

| Alloy 5056 USA | Bal | 0.3 max | 0.4 max | 0.10 max | 0.05/0.20 | 0.05 / 0.20 | 4.50 / 5.6 | - | - | 0.10 max | 0.05 each | 0.15 max |

| Alloy 5056A EWAA | Bal | 0.4 max | 0.5 max | 0.10 max | 0.10 / 0.6 | 0.20 max | 4.50 / 5.6 | 0.10 / 0.6 | 0.20 max | 0.20 max | 0.05 max | 0.15 max |

| Physical Properties of 5056-O | Metric | English | Comments |

| Density | 2.64 g/cc | 0.0954 lb/in³ | AA; Typical |

| Mechanical Properties | Metric | English | Comments |

| Hardness, Brinell | 65 | 65 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 88 | 88 | Converted from Brinell Hardness Value |

| Hardness, Vickers | 75 | 75 | Converted from Brinell Hardness Value |

| Tensile Strength, Ultimate | 290 MPa | 42000 psi | AA; Typical |

| 41.0 MPa @Temperature 371 °C | 5950 psi @Temperature 700 °F | ||

| 76.0 MPa @Temperature 316 °C | 11000 psi @Temperature 601 °F | ||

| 110 MPa @Temperature 260 °C | 16000 psi @Temperature 500 °F | ||

| 152 MPa @Temperature 204 °C | 22000 psi @Temperature 399 °F | ||

| 214 MPa @Temperature 149 °C | 31000 psi @Temperature 300 °F | ||

| 290 MPa @Temperature 24.0 °C | 42100 psi @Temperature 75.2 °F | ||

| Tensile Strength, Yield | 152 MPa | 22000 psi | AA; Typical |

| 28.0 MPa @Temperature 371 °C | 4060 psi @Temperature 700 °F | ||

| 48.0 MPa @Temperature 316 °C | 6960 psi @Temperature 601 °F | ||

| 69.0 MPa @Temperature 260 °C | 10000 psi @Temperature 500 °F | ||

| 90.0 MPa @Temperature 204 °C | 13100 psi @Temperature 399 °F | ||

| 117 MPa @Temperature 149 °C | 17000 psi @Temperature 300 °F | ||

| 150 MPa @Temperature 24.0 °C | 21800 psi @Temperature 75.2 °F | ||

| Elongation at Break | 35 % @Temperature 24.0 °C | 35 % @Temperature 75.2 °F | |

| 55 % @Temperature 149 °C | 55 % @Temperature 300 °F | ||

| 65 % @Temperature 204 °C | 65 % @Temperature 399 °F | ||

| 80 % @Temperature 260 °C | 80 % @Temperature 500 °F | ||

| 100 % @Temperature 316 °C | 100 % @Temperature 601 °F | ||

| 130 % @Temperature 371 °C | 130 % @Temperature 700 °F | ||

| 35 % @Diameter 12.7 mm | 35 % @Diameter 0.500 in | AA; Typical | |

| Modulus of Elasticity | 71.0 GPa | 10300 ksi | AA; Typical; Average of tension and compression. Compression modulus is about 2% greater than tensile modulus. |

| Poissons Ratio | 0.33 | 0.33 | Estimated from trends in similar Al alloys. |

| Fatigue Strength | 138 MPa @# of Cycles 5.00e+8 | 20000 psi @# of Cycles 5.00e+8 | completely reversed stress; RR Moore machine/specimen |

| Shear Modulus | 25.9 GPa | 3760 ksi | |

| Shear Strength | 179 MPa | 26000 psi | AA; Typical |

| Electrical Properties | Metric | English | Comments |

| Electrical Resistivity | 0.00000598 ohm-cm @Temperature 20.0 °C | 0.00000598 ohm-cm @Temperature 68.0 °F | AA; Typical |

| Thermal Properties | Metric | English | Comments |

| CTE, linear | 22.5 µm/m-°C @Temperature -50.0 - 20.0 °C | 12.5 µin/in-°F @Temperature -58.0 - 68.0 °F | |

| 24.1 µm/m-°C @Temperature 20.0 - 100 °C | 13.4 µin/in-°F @Temperature 68.0 - 212 °F | AA; Typical; average over range | |

| 25.2 µm/m-°C @Temperature 20.0 - 200 °C | 14.0 µin/in-°F @Temperature 68.0 - 392 °F | ||

| 26.1 µm/m-°C @Temperature 20.0 - 300 °C | 14.5 µin/in-°F @Temperature 68.0 - 572 °F | ||

| Specific Heat Capacity | 0.904 J/g-°C | 0.216 BTU/lb-°F | |

| Thermal Conductivity | 117 W/m-K | 810 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 568.3 - 638 °C | 1055 - 1180 °F | AA; Typical range based on typical composition for wrought products >= 1/4 in. thickness |

| Solidus | 568.3 °C | 1055 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

| Processing Properties | Metric | English | Comments |

| Annealing Temperature | 413 °C | 775 °F | holding at a temperature not required |

| Hot-Working Temperature | 316 - 482 °C | 600 - 900 °F | |

| Component Elements Properties | Metric | English | Comments |

| Aluminum, Al | 92.9 - 95.4 % | 92.9 - 95.4 % | As remainder |

| Chromium, Cr | 0.05 - 0.20 % | 0.05 - 0.20 % | |

| Copper, Cu | <= 0.10 % | <= 0.10 % | |

| Iron, Fe | <= 0.40 % | <= 0.40 % | |

| Magnesium, Mg | 4.5 - 5.6 % | 4.5 - 5.6 % | |

| Manganese, Mn | 0.05 - 0.20 % | 0.05 - 0.20 % | |

| Other, each | <= 0.05 % | <= 0.05 % | |

| Other, total | <= 0.15 % | <= 0.15 % | |

| Silicon, Si | <= 0.30 % | <= 0.30 % | |

| Zinc, Zn | <= 0.10 % | <= 0.10 % | |

Product Show

|