Product Show

| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Aluminum Forgings |

|---|---|

| Brand Name: | JIMA |

| Model Number: | AL |

| Certification: | ISO9001-2008,SGS,ROHS. |

| Place of Origin: | CHINA |

| MOQ: | 1PCS |

| Price: | Negotiations |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 10000 pcs /per month |

| Delivery Time: | 15~30Days |

| Packaging Details: | Standard Export Wooden Pallet |

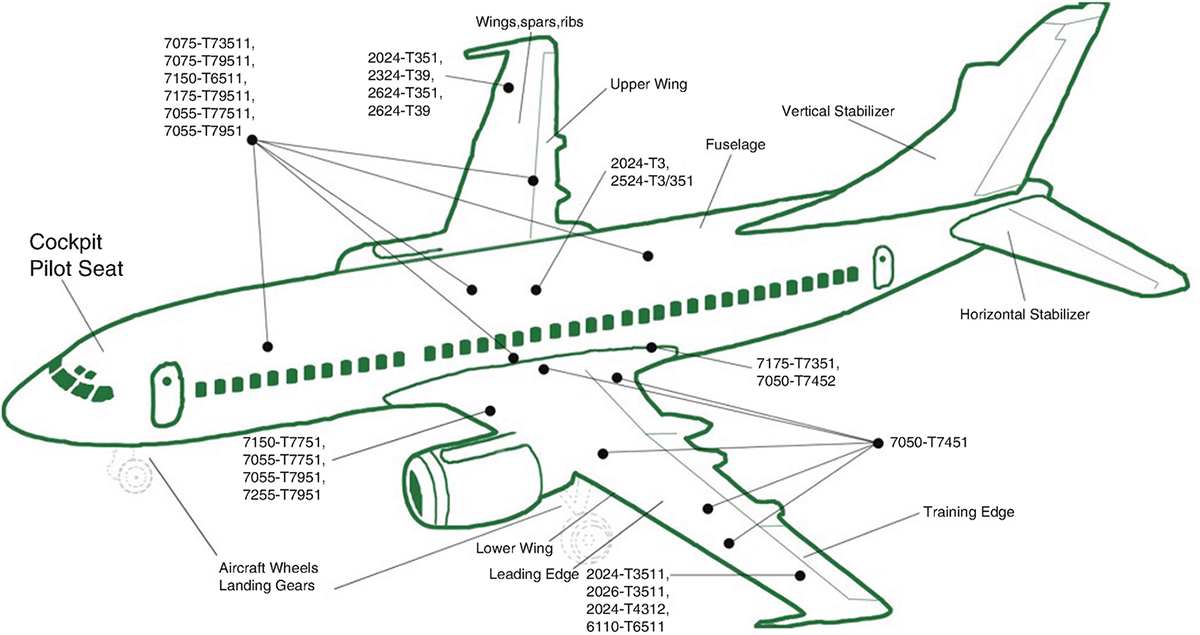

| Application: | Wheel Rim/Airplane |

| Standard: | JIS, DIN, BS, ASTM, SAE. |

| Alloy: | 2014/2A14 |

| Sample: | Can be Customized |

| Surface treatment: | Anodizing,Plating,Satin,Painting,Powder Coating,anodized etc |

| Process: | Forging |

| Name: | OEM 2014/2A14 Forged Aluminum Part for Wheel Rings, Truck Frame , Suspension Assembly, Fuel Tank ,Auto Parts Spare Parts |

| Mold: | Can Be Customized |

| Company Info. |

| JimaFor |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Details

| Material | Aluminum Alloy 2014/2A14 |

| Process | Forging+CNC+Heat Treatment |

| Surface Treatment | Transparent / Color Anodized;Hard Anodizing;Powder Coating; Sandblasting, Laser Carving, Silk Screening; Nickel-Plated, Chrome, Galvanized, Silver/Gold Plating; Black Oxide Coating; Polishing; etc... |

| Manufacture Ability | Depends on The Complexity Of Different Products And Quantities |

| Experience | Aluminum Machining Service for 12 Years |

| Packaging | Standard Export Wooden Pallets Another Request According to Your Need |

| MOQ | 1pcs |

| Sample | Can be Customized |

| Mold | Can be Customized |

| Lead Time | Mold for 15-20Days Process for 15-20Days |

| OEM | Can be Customized |

| Chemical Composition of 2014/2A14 | |||||||||||||

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Zn+Ti | Others | Al | ||

| Each | Total | ||||||||||||

| 2024/2A12 | 0.5-1.2 | 0.7max | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1max. | 0.25max | 0.15max | 0.2max | 0.05max | 0.15max | Rest | |

| High-Temperature Tensile Properties of 2014/2A14 Aluminum Alloy at Different Temperatures | ||||

| Temper | Temperature/℃ | Tension strength Rm/MPa | Prescribed plastic elongation strength Rp0.2/MPa | Elongation A (%) |

| T6 | 100 | 439 | 393 | 15 |

| 150 | 276 | 241 | 20 | |

| 204 | 110 | 90 | 38 | |

| T6 | 260 | 66 | 52 | 52 |

| 315 | 45 | 34 | 65 | |

| 370 | 30 | 24 | 72 | |

| Physical Properties | Metric | English | Comments |

| Density | 2.8 g/cc | 0.101 lb/in³ | AA; Typical |

| Mechanical Properties | |||

| Hardness, Brinell | 135 | 135 | AA; Typical; 500 g load; 10 mm ball |

| Hardness, Knoop | 170 | 170 | Converted from Brinell Hardness Value |

| Hardness, Rockwell A | 50.5 | 50.5 | Converted from Rockwell B |

| Hardness, Rockwell B | 82 | 82 | - |

| Hardness, Vickers | 155 | 155 | Converted from Brinell Hardness Value |

| Ultimate Tensile Strength | 483 MPa | 70000 psi | AA; Typical |

| Tensile Yield Strength | 414 MPa | 60000 psi | AA; Typical |

| Elongation at Break | 13 % | 13 % | AA; Typical; 1/2 in. (12.7 mm) Diameter |

| Modulus of Elasticity | 72.4 GPa | 10500 ksi | In Tension |

| Modulus of Elasticity | 73.1 GPa | 10600 ksi | AA; Typical; Average of tension and compression. The compression modulus is about 2% greater than tensile modulus. |

| Compressive Modulus | 73.8 GPa | 10700 ksi | |

| Notched Tensile Strength | 414 MPa | 60000 psi | 2.5 cm width x 0.16 cm thick side-notched specimen, Kt = 17. |

| Ultimate Bearing Strength | 889 MPa | 129000 psi | Edge distance/pin diameter = 2.0 |

| Bearing Yield Strength | 662 MPa | 96000 psi | Edge distance/pin diameter = 2.0 |

| Poisson's Ratio | 0.33 | 0.33 | |

| Fatigue Strength | 124 MPa | 18000 psi | AA; 500,000,000 cycles completely reversed stress; RR Moore machine/specimen |

| Fracture Toughness | 19 MPa-m½ | 17.3 ksi-in½ | KIC; TL orientation. |

| Machinability | 70 % | 70 % | 0-100 Scale of Aluminum Alloys |

| Shear Modulus | 28 GPa | 4060 ksi | |

| Shear Strength | 290 MPa | 42000 psi | AA; Typical |

| Electrical Properties | |||

| Electrical Resistivity | 4.32e-006 ohm-cm | 4.32e-006 ohm-cm | AA; Typical at 68°F |

| Thermal Properties | |||

| CTE, linear 68°F | 23 µm/m-°C | 12.8 µin/in-°F | AA; Typical; Average over 68-212°F range. |

| CTE, linear 250°C | 24.4 µm/m-°C | 13.6 µin/in-°F | Average over the range 20-300ºC |

| Specific Heat Capacity | 0.88 J/g-°C | 0.21 BTU/lb-°F | Estimated from trends in similar Al alloys. |

| Thermal Conductivity | 154 W/m-K | 1070 BTU-in/hr-ft²-°F | AA; Typical at 77°F |

| Melting Point | 507 - 638 °C | 945 - 1180 °F | AA; Typical range based on typical composition for wrought products 1/4 inch thickness or greater. Eutectic melting is not eliminated by homogenization. |

| Solidus | 507 °C | 945 °F | AA; Typical |

| Liquidus | 638 °C | 1180 °F | AA; Typical |

| Processing Properties | |||

| Annealing Temperature | 413 °C | 775 °F | |

| Solution Temperature | 502 °C | 935 °F | |

| Aging Temperature | 160 °C | 320 °F | Sheet, plate, wire, rod, bar, shapes, tube; 18 hr at the temperature |

| Aging Temperature | 171 °C | 340 °F | Forgings; 10 hr at the temperature |

Standard Specifications

ASTM B209

ASTM B210

ASTM B211

ASTM B221

ASTM B241

ASTM B247

ASTM BB241

DIN 3.1255

MIL T-15089

QQ A-200/2

QQ A-225/4

QQ A-250/4

QQ A-367

SAE J454

UNS A92014

Product Show

Application

|