| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Instrumentation Control Valves |

|---|---|

| Brand Name: | LINUO |

| Model Number: | Three-way ball valve |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, MoneyGram |

| Supply Ability: | 50 set / 30 days |

| Delivery Time: | 5-30 days upon order quantity |

| Packaging Details: | Wooden packing |

| Material: | Stainless steel |

| DN: | 15、20、25、32、40、50、65、80、100、125、150、200、300、350、400. |

| PN: | 1.0、1.6、2.5、4.0、6.4(Mpa)ASME150、300LB. |

| Temperature range: | -29~150℃,-40~425℃ |

| Company Info. |

| oepoch industrial technology |

| View Contact Details |

| Product List |

Three-way ball valve

Application

The three-way ball valve functions as a split and merge in the industrial pipeline. The T-type enables three orthogonal pipes to communicate with each other and the third channel to be cut. The L-three-way ball valve can realize the switching of the medium flow direction in the pipe. It is also possible to connect or close two channels that are perpendicular to each other. It is widely used in metallurgy, mining, petroleum, chemical, electric power, light industry, shipbuilding and other industrial sectors and automation control systems, suitable for mixing, diverting conditions of fluids, gases, dust media.

Feature

1, The fluid resistance is small, and its resistance coefficient is equal to the pipe length of the same length.

2, Close and reliable. At present, the sealing surface material of the ball valve has a good sealing property of PTFE, and it is also possible to use a hard-sealed valve seat weld alloy to improve wear resistance. A coil spring is used to provide a sealing force to ensure sealing performance.

3, Using the upper and lower valve stem fixed design, which there are upper and lower bearing positioning, ensure good mechanical stability and small starting torque. The bearing material is made of composite material, and its rotating shaft bearing surface is treated with sintered PTFE, which has superior wear resistance and self-lubricating function. This avoids the seizure of the valve during long-term use.

4, It is easy to operate and can be opened and closed quickly. From full-open to full-close, the spool rotates 90 degrees. Manual, pneumatic and electric actuators can be installed to facilitate remote control.

Technical Parameters

Nominal diameter (DN):15,20,25,32,40,50,65,80,100,125,150,200,300,350,400.

Nominal pressure (PN): 1.0,1.6,2.5,4.0,6.4(Mpa)ASME150,300LB.

Connection form: flange type.

Temperature range: -29~150℃,-40~425℃

Pressure test: The shell test pressure is 1.5 times the nominal pressure. The seal test is 1.1 times the nominal pressure. The test medium is water.

Leakage: Hard seal: Meet Class F of the ISO5208 seal rating, equivalent to the ANSI/FCI0.2IV x 1/100 standard.

Soft seal: Class ANSI/FCI-70.2VI.

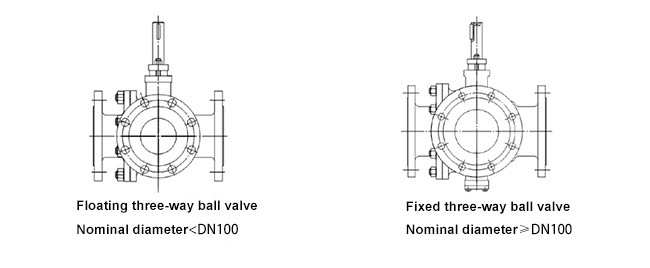

Structure type

Parts List

| Nunber | Name | Quantity(Piece) | Material |

| 1 | Valve body | 1 | WCB,CF8,CF8M |

| 2 | Bonnet | 1 | WCB,CF8,CF8M |

| 3 | Valve stem | 1 | WCB,CF8M+Hard chromium plating or spray welding Stelle |

| 4 | Valve seat | 2 | SS304,SS316+Hard chromium plating or spray welding Stelle |

| 5 | Bottom cover | 1 | WCB,CF8,CF8M |

| 6 | O-ring | 1 | EPDM,Fluororubber |

| 7 | Lower stem | 1 | SS304,SS316,20Cr13,17-4PH |

| 8 | Self-lubricating bearing | 1 | Suitable material |

| 9 | Back cover | 1 | WCB,CF8,CF8M |

| 10 | V type packing | A group | PTFE |

| 11 | Self-lubricating bearing | 1 | Suitable material |

| 12 | Flat key | 2 | 45#,SS304,SS316 |

| 13 | Upper stem | 1 | SS304,SS316,20Cr13,17-4PH |

| 14 | Packing gland | 1 | WCB,CF8,CF8M |

| 15 | Stud | 2 | SS304 |

| 16 | Hex nuts | 2 | SS304 |

| 17 | Vavle seat | 1 | SS304,SS316+Hard chromium plating or spray welding Stelle |

| 18 | Spring | On demand | 17-4PH,X-750 |

| 19 | Support ring | 1 | SS304,SS316 |

| 20 | Socket head cap screws | On demand | SS304 |

| 21 | Support ring gland | 1 | SS304,SS316 |

| 22 | Middle flange washer | 1 | PTFE |

| 23 | O-ring | 1 | EPDM,Fluororubber |

| 24 | Stud | On demand | SS304 |

| 25 | Hex nuts | On demand | SS304 |

Actuator configuration table

| DN | ZSQ double acting | DN | ZSQ double acting |

| 25 | ZSQ41-φ80-φ16 | 125 | ZSQ60-φ160-φ30 |

| 32 | ZSQ41-φ80-φ16 | 150 | ZSQ80-φ200-φ40 |

| 40 | ZSQ50-φ100-φ20 | 200 | ZSQ80-φ250-φ45 |

| 50 | ZSQ50-φ100-φ20 | 250 | ZSQ130-φ300-φ60 |

| 65 | ZSQ50-φ125-φ25 | 300 | ZSQ130-φ350-φ70 |

| 80 | ZSQ50-φ125-φ30 | 350 | ZSQ160-φ400-φ80 |

| 100 | ZSQ60-φ160-φ30 | 400 | ZSQ160-φ450-φ80 |

Double acting actuator configuration of conventional pressure PN16.

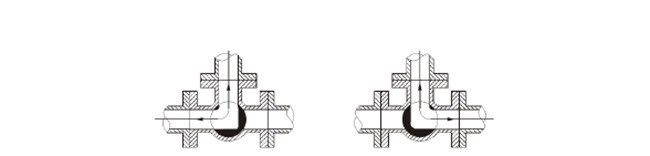

Valve seat seal structure

Floating soft seal seat(DN<100) Fixed soft seal seat(DN>100) Floating hard seal seat(DN>100)

| No. | Item | Temperature | No. | Item | Temperature | No. | Item | Temperature |

| 1 | Spool | -40~150℃ | 1 | Spool | -40~150℃ | 1 | Spool | -40~230℃ |

| 2 | O ring | 2 | O ring | 2 | O ring | |||

| 3 | Vavle body | 3 | Spring | 3 | Spring | |||

| 4 | O ring | 4 | O ring |

Three-way ball valve flow diagram

L-type three-way ball valve flow diagram

T-type three-way ball valve flow diagram

Order T-type three-way ball valve to confirm flow direction

Pneumatic three-way ball valve outline drawing

| Nominal diameter | Size(mm) | ||||||

| DN(mm) | L | h | H | L1 | L2 | L3 | L4 |

| 25 | 190 | 57 | 280 | 285 | 430 | 95 | 65 |

| 32 | 200 | 70 | 300 | 285 | 430 | 100 | 68 |

| 40 | 210 | 75 | 310 | 325 | 485 | 105 | 75 |

| 50 | 220 | 83 | 340 | 325 | 485 | 110 | 85 |

| 65 | 250 | 93 | 352 | 340 | 500 | 125 | 100 |

| 80 | 290 | 100 | 370 | 340 | 500 | 145 | 127 |

| 100 | 370 | 150 | 427 | 360 | 540 | 185 | 150 |

| 125 | 380 | 163 | 440 | 360 | 540 | 190 | 166 |

| 150 | 510 | 192 | 506 | 515 | 760 | 255 | 190 |

| 200 | 580 | 232 | 573 | 515 | 780 | 290 | 238 |

| 250 | 670 | 278 | 692 | 750 | 1090 | 335 | 238 |

| 300 | 760 | 350 | 760 | 750 | 1090 | 380 | 380 |

| 350 | 850 | 400 | 850 | 800 | 1230 | 425 | 390 |

| 400 | 980 | 460 | 970 | 800 | 1230 | 490 | 425 |

| 450 | 1080 | 505 | 1050 | 800 | 1230 | 540 | 500 |

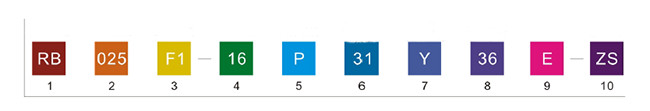

Model description

1.Valve type

RD | Three-way ball valve |

2.Nominal diameter

| GB/American Standard Series | ||

| 015 DN15 1/2″ | 065 DN65 1-1/2″ | 250 DN250 10″ |

| 020 DN20 3/4″ | 080 DN80 2″ | 300 DN300 12″ |

| 025 DN25 1″ | 100 DN100 3″ | 350 DN350 14″ |

| 032 DN32 1-1/4″ | 125 DN125 5″ | 400 DN400 16″ |

| 040 DN40 1-1/2″ | 150 DN150 6″ | |

| 050 DN50 2″ | 200 DN200 8″ | |

3. Connection method

| F1 Flange type (RF side) | F2 Flange type (MF side) |

4. Nominal pressure, pound

| GB series | American standard series | Japanese standard series |

| 10 PN10 | 01 150LB | 1K 10K |

| 16 PN16 | 03 300LB | 2K 20K |

| 25 PN25 | ||

| 40 PN40 | ||

| 64 PN64 |

5. Body material

| Material | |||

| C | WCB | G | CG8M |

| P | CF8 | B | LCB |

| Q | CF3 | D | LCC |

| M | CF8M | W | WC6 |

| L | CF3M | ||

6. Spool material and surface treatment

| Spool material | Surface treatment | ||

| 3 | CF8 | 0 | Polishing |

| 4 | CF3 | 1 | Chrome |

| 5 | CF8M | 3 | Spraying nickel-based alloy |

| 6 | CF3M | 4 | Spray welding tungsten carbide |

| 7 | CG8M | 5 | Ion nitridation |

| 6 | Spray-welded Stilerite Alloy |

7. Seat seal form

| Ordinary hard seal | Y |

| High temperature structural hard seal | G |

| Soft seal | R |

8. Seat material and surface treatment

| Hard seal | Soft seal | |||

| Seat material | surface treatment | Material | ||

| 3 304 | 0 | Polishing | PO | PTFE |

| 4 304L | 1 | Chrome | RO | PTFE |

| 5 316 | 3 | Spraying nickel-based alloy | NO | NYLON |

| 6 316L | 4 | Spray welding tungsten carbide | LO | PPL |

| 7 317 | 5 | Ion nitridation | KO | PEEK |

| 6 | Spray-welded Stilerite Alloy | |||

9. O-ring material

| Material and operating temperature | ||

| E | EPDM | operating temperature -29℃~120℃ |

| V | VITON | operating temperature -29℃~200℃ |

| A | PFA | operating temperature -40℃~230℃ |

| F | FEP | operating temperature -40℃~160℃ |

| G | Graphite ring(High temperature structure) | operating temperature -40℃~425℃ |

10. Drive mode

| ZS | Pneumatic double acting |

| ZDK | Pneumatic single acting air opening |

| ZDB | Pneumatic single acting air closing |

| ZK | Electric |

| SD | Manual |

|