| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Light Steel Keel Roll Forming Machine |

|---|---|

| Brand Name: | LBM |

| Model Number: | LBM-LSK-004 |

| Certification: | ISO: 9001: 2008 |

| Place of Origin: | Wuxi City, Jiangsu |

| MOQ: | 1 |

| Payment Terms: | L/C, T/T |

| Delivery Time: | 30 work days |

| Price: | Negotiation |

| Supply Ability: | 25 Sets per Month |

| Packaging Details: | Standard export packing with each machine fixed and protected in the container |

| Size: | 4500mm*600mm*1050mm |

| Weight: | 2.5 Tons |

| Rolling speed: | 8-12m/min |

| Roller station: | 11 stations |

| oller material: | No. 45# Steel Chrome Plated |

| Roller size: | Dia 70mm |

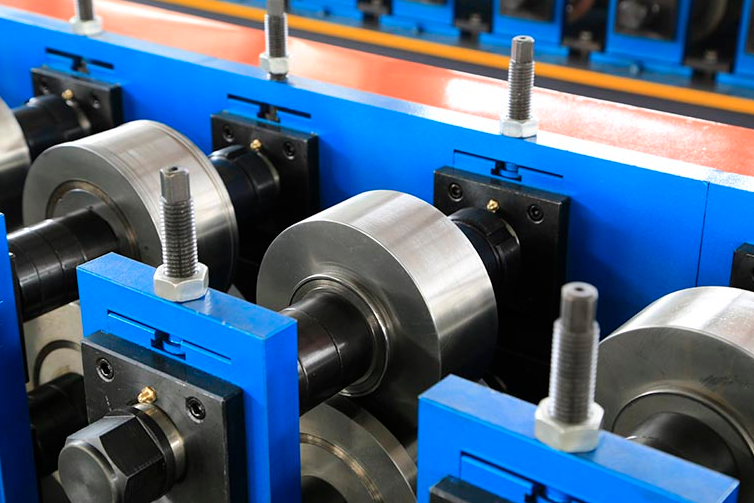

Channel Forming Light Steel Keel Roll Forming Machine Engineers Available to Service

1. Description of the light steel keel roll forming machine

Due to the technology monopoly, there are rarely Chinese manufacturers can provide steel framing solutions for lightweight or light gauge steel buildings, but for a light steel keel roll forming machine production, Chinese manufacturers are no-doubt reliable.

A light steel keel roll forming machine usually consists of manual decoiler, a feeding guide unit, a punching tool, a roll forming unit, a cutting unit, a transmission unit, a hydraulic unit, a control unit, and runout tables. Under PLC control system, this drywall stud and track roll forming machine fully automatically produce 4-6 metal c studs or u tracks out of galvanized steel of 0.6-1.2mm thickness from punching, roll forming and cutting.

Like other light steel keel roll forming machine, a ceiling roll forming machine works at a speed 8- 12m/min. Under the PLC control system, this ceiling roll forming machine cut the final products as per required lengths and quantities. In addition, chains-sprockets transmission is typical transmission method for a ceiling roll forming machine.

2. Main technical parameters of the light steel keel roll forming machine

| 1 | Name of commodity & specification | Light steel keel roll forming machine |

| 2 | Main motor power | 3 KW, 3 Phase |

| 3 | Hydraulic motor power | 3 KW |

| 4 | Hydraulic Pressure | 10-12 MPa |

| 5 | Voltage | 380V /3phase/ 50 HZ |

| 6 | Control System | PLC Delta Converter |

| 7 | Main Frame | 300mm H-Beam |

| 8 | Backboard Thickness | 14mm |

| 9 | Chain Size | 20mm |

| 10 | Feeding Material | color steel coils |

| 11 | Feeding Thickness | 0.3-1.2mm |

| 12 | Productivity | 8-12m/min |

| 13 | Roll Station | 11 stations |

| 14 | Roller Diameter | Dia 70mm |

| 15 | Roller material | 45# steel |

| 16 | Cutter material | Cr12 , quenched |

| 17 | Cr-Plating Size | 0.05mm |

| 18 | Overall Size | 3000×800×1000mm |

| 19 | Total Weight | 2.5T |

3. Introduction of the feature of the light steel keel roll forming machine

| No. | Description |

| 1 | Adopt Windows system touch panel Can input NC instructions Via network or USB interface quickly |

| 2 | Adopt visual work process monitoring |

| 3 | Equip Vertex BD Software |

| 4 | Adopt German Bosch Rexroth hydraulic system. Quick loading & unloading mold design |

| 5 | High quality die steel. Vacuum hardening treatment. CNC Machine Center Finishing |

| 6 | Built-in maintenance free inkjet printer |

| 7 | Perfect forming and accurate sizing |

4. Main components for light steel keel roll forming machine

| Components for light steel keel roll forming machine | ||

| Name | Quantity | Units |

| Passive Uncoiler | 1 | Set |

| Feeding Device | 1 | Set |

| The Main Roll Forming Unit | 1 | Set |

| Hydraulic Cutter | 1 | Set |

| Hydraulic Station | 1 | Set |

| PLC System | 1 | Set |

| Ran-out Table | 1 | Set |

5. FAQ

Q: How to maintenance?

A: If using frequently, best coating lubricant on the chain and two

ends of the shaft every month,

replace the hydraulic oil every 1-2 years.

Q: Can you be responsible for transport?

A: Yes, please tell me the destination port or address.we have rich

experience in transport.

Q: Can you make the machine according to my design or photo type?

A: Yes. We have an experienced team for working out the most

suitable design and production

Q: How many workers operate this machine to manufacture?

A: Only 1-2 worker.

Q: Can you supply the raw materials?

A: Yes, we can supply the galvanized steel coil, aluminum steel

coil, color steel coil

Q: How is this machine's service life?

A: In the normal maintenance, the service life at least 8 years.

|