| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Glazed Tile Roll Forming Machine |

|---|---|

| Brand Name: | Feixiang |

| Model Number: | FX796 |

| Certification: | CE BV ISO |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Please check with the supplier |

| Payment Terms: | L/C, T/T, D/P, D/A, Western Union, MoneyGram |

| Supply Ability: | 30 sets per week |

| Delivery Time: | 15 days |

| Packaging Details: | Nude packing,but we can also packing according the customer requirements |

| Machine name: | Galvanized Roof Panel Roll Forming Machine , Roofing Sheet Roll Forming Machine |

| size: | 7200*1350*1250mm |

| Weight: | 5.6tons |

| Control: | PLC computer with different language |

| Speed: | 2-5m/min |

| Material: | GI,PPGI.AL |

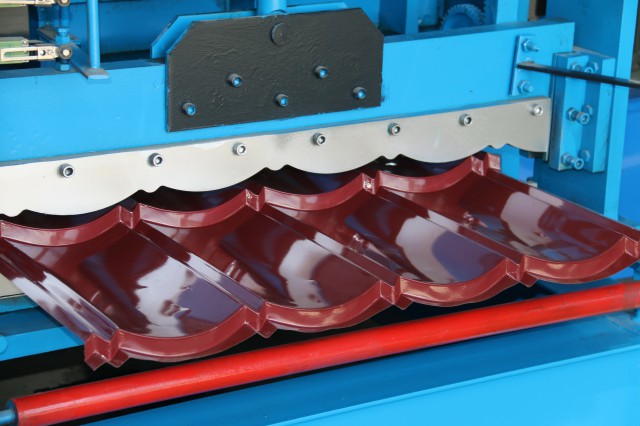

Galvanized Roof Panel Roll Forming Machine , Roofing Sheet Roll

Forming Machine

The raw material of the glazed tile forming machine is galvanized

steel, different color steel or aluminum plate, roll forming die.

Glazed tile molding machine produces the rich color glazed tile,

strong corrosion resistance, for the new building materials, with

special paint, rich colors, classical and elegant, finishing touch

for your building. Its light weight, high strength, good

waterproof, easy to install.

1. Main Material used

Material: Color steel ,galvanized steel or Aluminum

Feeding width:914mm

Material thickness:0.3-0.8mm

Yield strength:235-450mpa

2. Machine details

Brand: Feixiang

Model number: FX796

Voltage requirement: 380v60hz3p

Working speed:2-4m/min

3. Machine composition

No. | Name | Unit | Qty |

1 | Decoiler | set | 1 |

2 | Main Machine for roll forming | set | 1 |

3 | Control System(PLC) | set | 1 |

4 | Pressing System | set | 1 |

5 | Cutting System | set | 1 |

6 | Output Table | set | 1 |

4. Main parameters

Model number | Galvanized Roof Panel Roll Forming Machine , Roofing Sheet Roll Forming Machine |

Rolled material | 0.3-0.8mm thickness, aluminum sheet, galvanized sheet, colored steel sheet |

Effective width | 796mm |

Feeding width | 914mm |

Forming steps | 13 stations |

Roller | 45# forged steel, hard chrome plating within 0.05mm |

Diameter of shaft | 80mm |

Main motor power | 5.5 kw |

Pump power | 3 kw |

Sprocket chain | 1 inch |

Drive type | by chain |

Cutting Blade | Cr12, heat treatment 60-62°C |

Frequency Converter | It has the advantage of slowing down before cutting, |

component | 1 set of manual decoiler,1 set of main roll forming machine, |

Payment terms | cash,T/T,L/C. |

Delivery time | 30 working days |

|