| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Downspout Roll Forming Machine |

|---|---|

| Model Number: | JK-215 |

| Certification: | CE |

| MOQ: | 1 set |

| Price: | Negotiated |

| Payment Terms: | T/T, L/C, Western Union |

| Supply Ability: | 20 sets per month |

| Delivery Time: | Shipped in 15 days after payment |

| Packaging Details: | 1.Tighten to container with steel wire rope and welded angel iron. 2.Main forming machine and unciler is naked (if you need we can also packed with water-proof plastic) 3.Roll forming machinePLC control system and moter pump are packed with water-proof p |

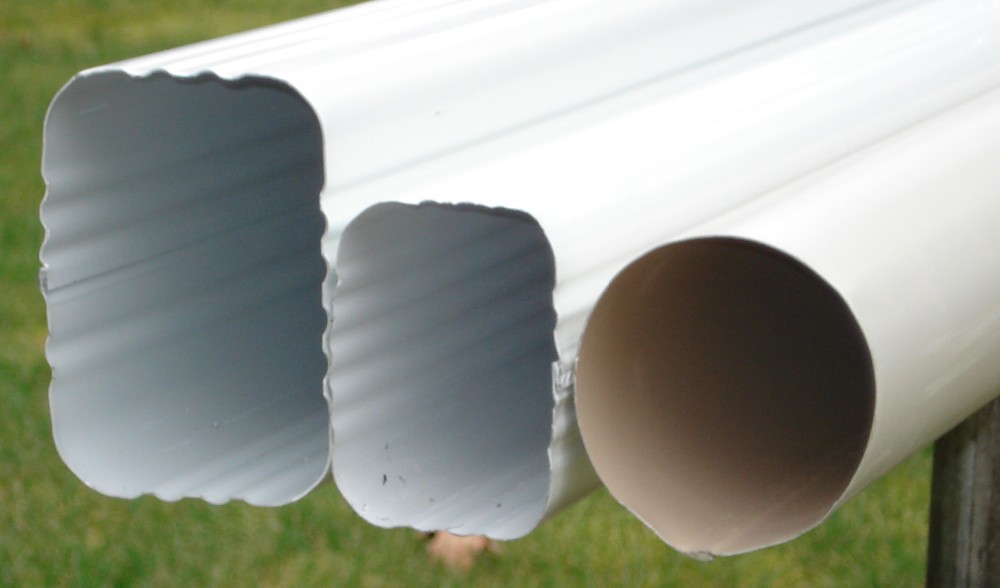

| Usage:: | Use To Produce Rain Gutters |

| Production Capacity:: | 8-12 m/min |

| Voltage:: | 380 v, 50 hz ,3 phase |

| Power(W):: | 3 kw |

| Dimension(L*W*H):: | 7.9*1.3*1.1m(L*W*H) |

| Control System:: | PLC with Touch Screen |

| Material Thickness:: | 0.3-0.8mm |

| After-sales Service Provided:: | Overseas service center available |

| Company Info. |

| RFM Cold Rolling Forming Machinery |

| Verified Supplier |

| View Contact Details |

| Product List |

Downspout Roll Forming Machine For Wall Cladding Contruction Material

1. Technical Parameter

Item NO. | Description | Offered Specification |

| 1.0 | Roll forming machine | |

| 1.1 | Rolling speed | 10-15m/min(not include cutting time) |

| 1.2 | Rolling thickness | 0.3--2.0 mm |

| 1.3 | Raw material | Galvanized steel sheet |

| 1.4 | Dimension | 3500×1600×1500(mm) |

| 1.5 | Effective width | 60mm |

| 1.6 | Roller stations | 20 stations One stage for embossing |

| 1.7 | Roller material | 45#forge steel, coated with chrome |

| 1.8 | Shaft diameter | Φ70mm ,material is 45# forge steel |

| 1.9 | Transmission | By chain 1 inch |

| 1.10 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.11 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.12 | Tolerance | 6m+-0.05mm |

| 1.13 | Frame | H type steel |

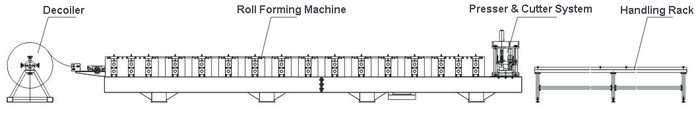

2. Main Components

| Serial No. | Commodity & Description | Quantity |

1 | 3T manual uncoiler | 1 set |

2 | Infeed guiding | 1 set |

3 | Main roll forming machine | 1 set |

4 | straighten device | 1 set |

5 | Hydraulic cutting equipment | 1 set |

6 | Output table | 2 sets |

7 | Main drive | 1 set |

8 | Hydraulic system | 1 set |

9 | Controlling system (including cabinet) | 1 set |

10 | Downpipe elbow forming machine | 1 set |

11 | seaming machine | 1 set |

3. Working Flow of Roll Forming Machine

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

4. Advantage for Roll Forming Machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

During the warranty period, maintain and change the spare parts for

the customers for free (except for the instrument damage caused by

human factors or natural disasters. ) And provide technical support

for life-long.

We can design and manufacture the machine according to clients'

request! Our machines have passed CE, Guaranteed quality. Please

send us the enquiry with Profile Drawing.

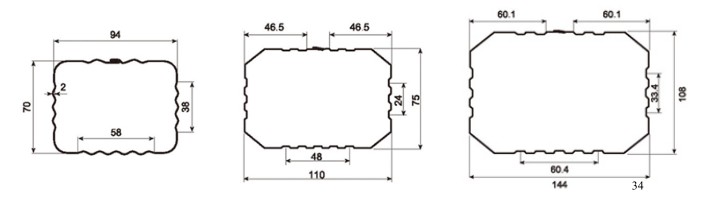

5. Profile of product

Package and Loading

Our roll forming machine is fixed in the container with steel ropes so that the machine is kep from being collided, and treatment for rust proof, covered by plastic film for the whole machine, spare parts and some small parts packed in wooden box.

|