| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cold Roll Forming Machine |

|---|---|

| Brand Name: | TECHWELL |

| Model Number: | TW-RWM |

| Certification: | CE, ISO |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | Contact Us |

| Payment Terms: | 40% T/T in advance, 60% T/T before shipment |

| Supply Ability: | 20 Sets |

| Delivery Time: | 55-65 working days |

| Packaging Details: | Export Package |

| Profile Description: | Roof Sheet for making the pu panels |

| Forming Structure: | Welded wall plate strcuture |

| Shaft material: | 45# high grade steel tempering treatment (HB220-260) |

| Shaft diameter: | 75mm |

| Roller material: | 45# high grade steel, and roller surface with hard chrome ≥ 0.05mm |

| Forming station: | 18 stations |

| Company Info. |

| Wuxi Techwell Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Reasonable Cold Roll Forming Machine For PU Roof Panels , PPGI Galvanized Steel Raw Material

Main Technical Specifications

1). 5 Ton Manual Decoiler 1. Decoiler Type: Manual type decoiler 2. Weight Capacity of Decoiler: 5Ton 3. Manual expanding 4. Passive uncoiling 5. I.D: 508mm |

2). Main Roll Forming Part 1. Forming material thickness: 0.3-0.7mm 2. Forming material type: PPGI, GI 3. Machine frame: high grade steel welded and tempering treatment 4. Forming structure: Welded wall plate strcuture 5. Forming motor: 7.5KW 6. Shaft material: 45# high grade steel tempering treatment (HB220-260) 7. Shaft diameter: 75mm 8. Roller material: 45# high grade steel, and roller surface with hard chrome ≥ 0.05mm 9. Forming speed: about 0-15m/min (excluding cutting time) 10. Forming station: ≈ 18 stations |

3). Hydraulic Cutting & Hydraulic Station 1. Cutting type: Hydraulic cutting after roll forming, Burr-free cutting 2. When cutting, Machine stop 3. Cutting blade: 1 SET 4. Cutting blade material: Cr12Mov, Quench treatment, HRC58-62 5. Hydraulic station power: 4KW 6. Hydraulic pressure: 15Mpa 7. Cutting Tolerance: +/-1.5mm |

4). Electrical Control System 1. The entire line is controlled by imported PLC, LCD touch screen human-machine interface. People interact with the PLC. Operator by setting the program to run automatically (programmable control) to monitor and control process, to achieve the operator to control the production line and modify the control parameters, and real-time monitoring of equipment status, operating parameters and fault indication. Work piece length digital setting, work piece length adjustable. Real-time monitoring of equipment operating status and fault indication. 2. Operation: manual / automatic. It is convenient to maintenance with the manual model and there are emergency stop bottom on it. |

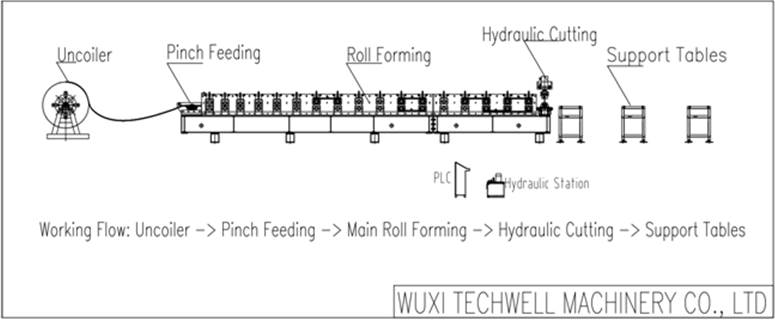

Decoiler / Uncoiler --- Pinch Feeding --- Main Roll Forming --- Hydraulic Cutting --- Support Table

Main Components

Competitive Advantages

More Machine Pictures

Contacts of WUXI TECHWELL

| Company | Wuxi Techwell Machinery Co.,Ltd | |

| Website | www.wxtechwell.com | |

| www.cold-rollformingmachine.com | ||

| www.roofrollformingmachine.com | ||

| Tel/Fax | 0086-510-83133431 | |

| Mobile / Whatsapp / Wechat | 0086-15861597732 (Miss Lemon) | |

| E-Mail/Skype | sales@wxtechwell.com | |

|