| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Shutter Roll Forming Machine |

|---|---|

| Brand Name: | BOSJ |

| Model Number: | BOSJ-F |

| Certification: | ISO,CE,SGS |

| Place of Origin: | JIANGSU |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T |

| Supply Ability: | 2 sets per month |

| Delivery Time: | 50 days |

| Packaging Details: | wooden cases,plastic packing |

| Machine Control Power: | Hydraulic type |

| Production Speed: | 8-10m/min |

| Method: | Vacuum Extruder |

| Roller Material: | GCR15 |

| Roller Axis: | 60mm |

| Material Thickness: | 0.5-1.5mm |

| Final Product: | Sample Drawings provided |

| Working Method: | Automatic |

Auto Fire Damper Shutter Frame Blade Louver Roll Forming Machine

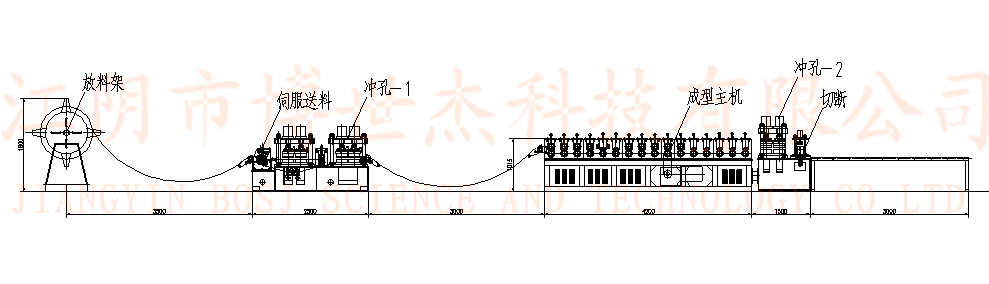

1, Structure of equipment

This line is composed of de-coiler, punching, forming machine,

cutting system, electric control system, etc.

2, Equipment composing parts

Equipment is composed of de-coiler, feed system, gap and cut off,

forming machine, collection table, electric control system, etc.

3, Technical parameter of equipment main parts

3.1, Auto-decoiler

A, Load capacity: 2 T

B, Inner diameter of coil: 490-510mm

Outer diameter≤ 1200mm

3.2. Servo feed and punching unfilled corner parts

A, Servo motor: Used Mitsubishi Servo motor, power: 1.0kw

B, Punching unfilled corner die: 4 pillars punching die

C, Material of punching die: Cr12. Quenching treatment

3.3Feeding:

Power 0.37kw

3, 4Forming machine

A, Forming frame

B, Material of forming mould: GCr15, quenching treatment: Rigidity:

HRC56-62º

C, Motor: 7.5kw frequency conversion engine

4, Electric control: PLC system

The operator can do the following

· The setting program (PLC)

· Monitoring the control process,

· Modify the control parameters,

· The length of the workpiece digital setting,

· The length of the workpiece adjusting.

· Running state real-time monitoring equipment and fault

indication.

2- Mode of operation: manual / auto two. With manual, automatic

switching function: in the manual mode, can be stand-alone

operation, convenient repair; in the automatic mode, all production

and operation, the start up sequence; along with the emergency stop

button, easy to handle emergencies, to ensure the safety of

equipment and personnel

Main Parameter

NO. | Project | Unit | parameters | Remark | |

1 | Material | type | Mild steel,Galvanized sheet | ||

| Strengthof material sheet | Map | ≥350 | |||

| Thickness of material sheet | mm | 0.8~1.5 | |||

| 2 | Size of production | mm | Reference the picture | ||

| 3 | Production speed | m/min | 6~8 | ||

| 4 | Material of roller | GCr quenching treatment | |||

| 5 | Drive type | Gear box | |||

| 6 | Power | kw | About 34 | ||

| 7 | Electric control system | PLC variable frequency control | |||

| 8 | Dimensions(Length*width*height) | m | 28X4X3.9 | ||

Product Pictures

|