| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cable Tray Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-CT |

| Certification: | CE,SGS,ISO |

| Place of Origin: | Jiangsu,China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 5 sets per month |

| Delivery Time: | 90days after deposit |

| Packaging Details: | Film and steel wire |

| Width of the profile: | 100-500mm |

| Hydraulic Station Power: | 7.5KW |

| Driven system: | Chain Driven 1.5 inches 20A double chain with longer shafts |

| Main Power: | 18.5KW |

| Rolling Speed: | 10-12m/min |

| Electric Source: | 380V, 50HZ,3 phase |

| Material: | 1.5-2mm Galvanized steel or blank steel |

| PLC: | Panasonic brand |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

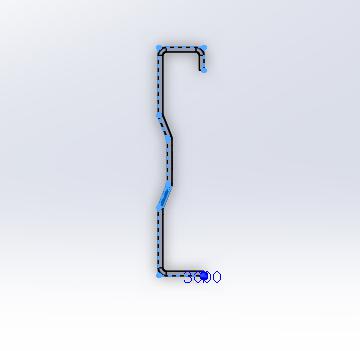

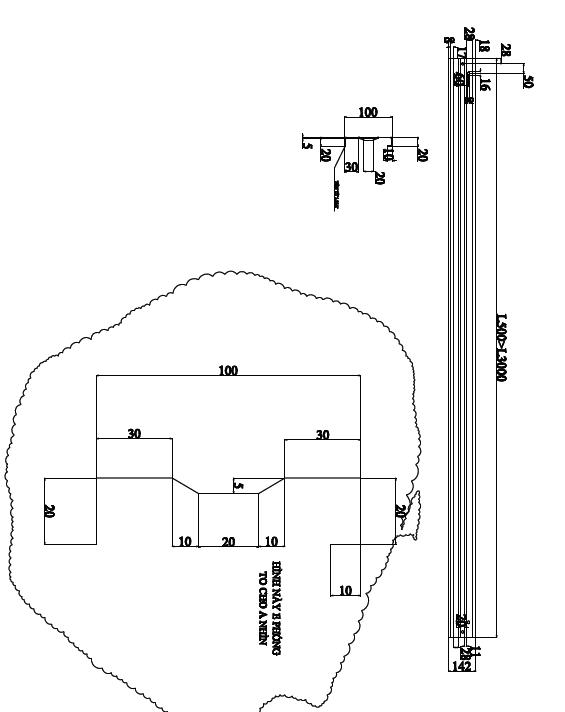

Steel Channel Ladder Cable Tray Making Cold Roll Forming Machine

Cable tray roll forming machine is commonly used for cable management in commercial and industrial construction. This roll former could produce different types of cable trays like: Solid bottom cable tray, Trough cable tray, Channel cable tray, ladder cable tray, Perforated cable tray, Non perforated cable tray and Trunking cable tray etc. with different raw materials like: hot-dip galvanized steel, pre-galvanized steel, hot-rolled and cold-rolled steel, stainless steel and aluminum. Thickness range of material is 0.6mm-1.2mm or 1-2mm. You could set up different lengths for cable tray. Our roll forming machine could produce wide range of sizes, and automatically change by motors from one size to the other not only at width but also at height. We make different solutions according to customers’ drawing, tolerance and budget, offering professional one-to-one service, adaptable for your every need.

Character of main structure

a) The machine has features of low noise and high efficiency.

b) All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

c) The structure is simple and the appearance of the machine is beautiful because we adopt the shape-steel structure and most of the connecter is screw which make the machine flexible and stronger.

d) It is very easy to install the equipment and suitable for producing in the factory.

e) We adopt the automatic length-fixed forming and cutting to guarantee the length to be precise and the finished product clear without deforming.

Technical Parameter

| Items | Specifications | |

| Width of the profile | 100-500mm | |

| Height of the profile | 50-200mm | |

| Thickness | 1.5-2.0mm | |

| Un Coiler | 5 tons hydraulic | |

| Forming system | Rolling Speed | 5-6m/min |

| Roller Stations | About 20 stations | |

| Roller Material | Gcr 15with quenching | |

| Shaft | Dia 90mm | |

| Maim Motor Power | 18.5kw | |

| Hydraulic cutting Power | 7.5kw | |

Cutting system | Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 | |

| Tolerance | +-1.5mm | |

| Electrical control system | Electric Source | 380V, 50HZ,3 phase Also can satisfy Customer’s require |

| Control System | PLC (Panasonic) as list in the note | |

| Profile adjustment | Control by the rails&motor | |

| Way Of Drive | 1 inch chain | |

| Size of machine | 30000mm* Width 1500mm* Height 1200m |

Main Machine

| 5 tons hydraulic de-coiler | 1 set |

| Roller Leveller | 1 set |

| Servo feeding machine | 1 set |

| Hydraulic punching | 1 set |

| Main roll forming machine | 1 set |

| PLC Control box | 1 set |

| Hydraulic cutting device | 1 set |

| Cutting blades | 1 set |

| Hydraulic station | 1 set |

| Out tables | 1 set |

Technological process

Uncoil—feeding with guide——Punching ——Roll forming———Cutting———Out

table

Standard profile

Our advantage

a. We as a manufacturer are specialized in all kinds of cold roll forming machine.

b. Customers'design, color and logo are also accepted! Our specialized experts and skilled workers keep devoting their hard working to ensure the machine with high quality.

c. Schneider PLC system:Ensuring high accuracy and easy to operate!Full Automatic: Just input length of the sheets and numbers of the piece you need, then the machine will start to work as your order.

d. Our machines exported to the Southeast Asia, Middle East, Africa, North & South America more than eighty countries and regions.We have professional team, complete production system, high quality products, good service.

ms.

Our Company

Sussman Machinery Co., Ltd., specialized manufacturer of roll

forming machinery for purlins, stud, decking. racking, roofing,

glazed tile, shutter doors, solar panel, pu sandwich line, ect. We

have more than 10 years production experience and have shipped our

machines to more than 80 countries.OEM is welcome here. Any

requirements just no hesitate to contact with us, we must try our

best to satisfy your needs. Reasonable price and best service will

be provided to you.We are very much glad to work with you.

We will attend PERU ARCON Expo

Booth Number:E126

Time:4th-7th,July,2018

Address: Lima Jokey Plaza International Exhibition Center

|