| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Double Layer Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SS-DL |

| Certification: | CE, ISO, SGS |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 12 sets/ month |

| Delivery Time: | 55 working days after accepting the advanced payment |

| Packaging Details: | Standard package with film, plastic and steel wire. (or customized) |

| Steel thickness: | 0.21-3.0 mm |

| Forming speed: | Fast than 16m/ min |

| Power supply: | 380V, 50Hz, 3Phase |

| Dirve system: | Chain driving |

| Control system: | PLC system |

| Machine weight: | about 10 tons |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Roof and wall panel double layer roll forming machine

Technical Parameter

Item NO | Description | Offered specification |

1.1 | Rolling speed | UP to 16 m/min(not include cutting time) |

1.2 | Rolling thickness | 0.21-3.0mm |

1.3 | Raw material | Color painted coils |

1.4 | Dimension | About 8000×1600×1200(mm) |

1.5 | Effective width | 836mm |

1.6 | Feeding Coil width | 1000mm |

1.7 | Roller stations | About 18 stations |

1.8 | Roller material | 45#forge steel, coated with chrome |

1.9 | Shaft diameter | Φ76mm |

1.10 | Transmission | By chain 1.2 inch |

| 1.11 | Material of chain | 45# forged steel with frequency quenching, 12A |

1.12 | Material of cutting | Cr12Mov with quench HRC58-62° |

1.13 | Tolerance | 10m+-1.5mm |

| 1.14 | Hydraulic station | 4kw |

Main Components

Commodity & Description | Quantity |

5T manual uncoiler | 1 set |

Leveing guiding | 1 set |

Servo feeding device | 1 set |

Main roll forming machine | 1 set |

Hydraulic station | 1 set |

Cutting device | 1 set |

Finished products tabel | 1 set |

PLC control system | 1set |

Out tables | 2 sets |

Spare parts | 1 set |

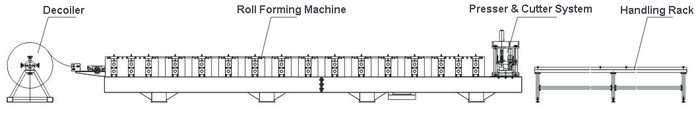

Working Flow of Roll Forming Machine

A.Passive

Decoiler..........................................................

B.Servo Feeding Applicator............................................

C.Hydraulic/Press Punching...........................................

D.Roll Forming Unit.........................................................

E.Hydraulic Cutting.........................................................

F.Output Table................................................................

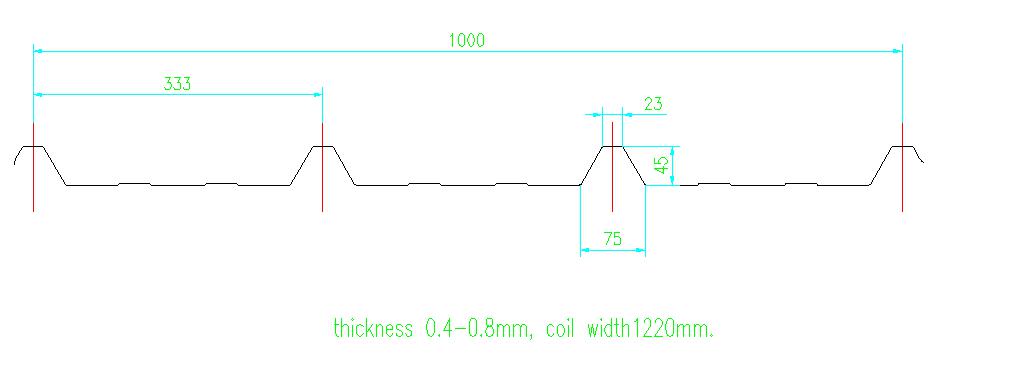

Standard Profile of Product

Loading pictures

After-sale Serive

- After machine arrive the destination, by the request of the buyer

, the seller will provide 1 technical engineer to guide

installation and training , and the buyer should give the technical

person with full cooperated.

- Installation period: about 7 days after the complete preparation

by the buyer such as the foundation and all necessary accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the buyer should

pay for installation and commissioning fee 100$/day to the point

account of the seller. The two-way ticket,visa, food, hotel , the

translator and insurance are all should provide by buyer with full

responsibility.

-The seller supply technical data (including forming mould drawing, electrical elements drawing and equipment drawing etc.)

|