| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roof Roll Forming Machine |

|---|---|

| Brand Name: | Shenghong |

| Model Number: | SWL151226-210 |

| Certification: | CE ISO |

| Place of Origin: | Jiangsu, China |

| MOQ: | 1 sets |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 25 SETS/ MONTH |

| Delivery Time: | 40 days after payment |

| Packaging Details: | 1. Export standard package for container 2. Host nude, wheels with oil and gas bubble cushion packaging. 3. PLC controller with bubble cushion packaging 4. Spare parts in wooden cases. |

| Cutter frame: | high quality 20mm steel plate |

| Steel thickness: | 0.4-0.8mm |

| Forming speed: | 8-18m/min |

| Roller stands: | 18 stands bottom layer, 16 stands top layer |

| Machine net weight: | 12 T |

| Power supply: | 380V 50HZ 3 phase |

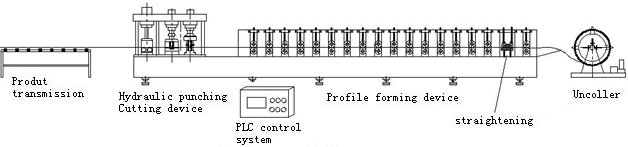

Corrugated Steel Sheet Double Layer Roll Forming Machine 0.4 - 0.8mm Thickness

Description of 2 Layer roll forming machine

The machine can be used to produce 2 different profiles of

corrugated steel sheet, e.g. 2 wall & roof sheets, or 1 wall & roof

sheet and 1 floor decking sheet. Customer can choose the type. This

line consists of uncoiler, cut-off unit, roll forming machine,

products stacker and PLC automatic control cabinet.

1.Variable frequency speed control

2.Multi-purpose for overlap connection

3.Auto power off

Layout of double-layer roll forming mill

Technical parameters of 2Layer roll forming machine

Steel thickness: 0.4-0.8mm

Forming speed: 8-18m/min

Roller stands: 18 stands bottom layer, 16 stands top layer

Roller material: 45# steel, coated with chrome

Main motor power: 5.5kw

Hydraulic cutting power: 3kw

Hydraulic pressure: 12Mpa

Power supply: 380V 50HZ 3 phase

Tolerance: 1.5mm

Control system: PLC with touch screen

Machine net weight: 12T

Typical double layer

Machinery Photos

Workshop Show

|