| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Air Separation Unit |

|---|---|

| Brand Name: | HANGYANG |

| Model Number: | KDON |

| Certification: | CE/ASEM/GB |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | according to actual requirement |

| Supply Ability: | according to actual requirement |

| Delivery Time: | according to actual requirement |

| Packaging Details: | wooden case, nude packing, container |

| Product Name: | KDON-2500/6000 Air separation unit |

| Application: | Glass,Oil and Gas Field,Machinery & Construction,Metallurgy |

| Output(Nm3/h): | 2500~3000 |

| Pressure: | 0.025/0.015 |

| Purity: | ≥99.6%O2 /5ppm(O2) |

| Material: | Carbon steel, Al, stainless steel |

| Delivery Term: | FOB Shanghai |

Air Separation Unit KDON-2500/6000 Nm3/h Fuel Gas Carrier Gas Air Separation Plant

Specifications:

Product List KDON-2500~3000 (GOX) Series Air Separation Unit

MODEL CONTENTS | KDON-2500/7500 | KDON-2500/2500 | KDON-2500 | KDON-1200/1000 | KDON-2650/5000 | |

GAN/LIN flow | Nm3/h | 7500 | 2500 | 150 | 1000 | 5000/240 |

GAN/LIN purity | ppm | ≤10ppmO2 | 10ppmO2 | ≤100ppmO2 | ≤10ppmO2 | ≤16ppmO2 |

GOX/LOX flow | Nm3/h | 2500 | 2500/500 | 2500/250 | 1200/400 | 2650 |

GOX/LOX purity | ppm | 99.6% O2 | 99.6% O2 | 99.6% O2 | 99.6% O2 | 99.6% |

GAN/LIN pressure | MPa | 0.01 | 0.015/0.25 | 0.005 | 0.3 | 0.005/0.2 |

GOX/LOX pressure | MPa | 0.025 | 0.025/0.16 | 0.0254 | 0.024/0.2 | 0.025 |

Typical Product: KDON-2500/6000 Air Separation Unit

Output, purity and pressure

Flow (Nm3/h) | Purity | Pressure MPa(G) | |

GAN/LIN | 6000/300 | 10ppm(O2) | 0.015/0.25 |

GOX/LOX | 2500/30 | ≥99.6%O2 | 0.025/0.16 |

Description:

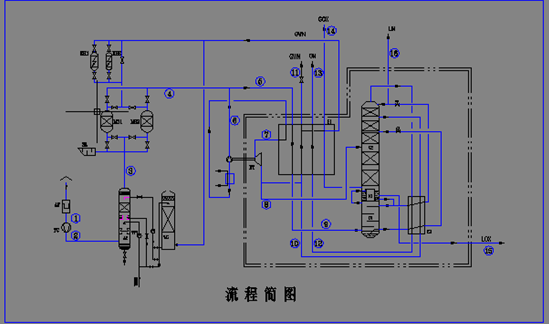

The process of this ASU is adopting normal temperature molecular sieve to purify air, boosting turbo expander to produce refrigerating capacity; the fractionating column adopts convection sieve trays.

The purified air is split into 3 parts: one part of compressed air is drawn out as instrument air; most part of air passes into lower column; the rest part of expanded air is fed into upper column for rectification after expanded air cooler.

After the preliminary rectification in the lower column, liquid air is obtained in the bottom of lower column, and pure liquid nitrogen is obtained from the top. After further rectifying in the upper column, product gaseous oxygen is obtained from the bottom of upper column, and fed to the client as product.

Draw the pure nitrogen gas and liquid nitrogen from the top of upper column. The nitrogen gas goes out of cold box after rewarmed in the main heat exchanger, and fed to the client as product. The liquid nitrogen out of cold box goes into storage tank.

Applications:

Competitive Advantage:

|