| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Guardrail Roll Forming Machine |

|---|---|

| Place of Origin: | wuxi, China |

| Brand Name: | CMC |

| Certification: | CE, ISO |

| MOQ: | 1 Set |

| Price: | Negotiate |

| Packaging Details: | The whole body covered with plastic bag. or according to the customers requirements. |

| Delivery Time: | According to the stocks |

| Payment Terms: | T/T,L/C,D/P |

| Supply Ability: | 50 Sets per month. |

| Condition: | New |

| Place of Origin:: | wuxi, China |

| Thickness: | 2.5~3.0mm |

| Width: | 450-476mm |

| Applicable Industries: | Construction works |

| Color: | User Defined |

| Company Info. |

| Wuxi CMC Machinery Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

guardrail roll forming machine for 4mm thickness sheet

we are a professional manufacturer engaged in designing and producing all types of high precision, hight tech, professionally designed cold roll forming machines. Using advanced technology and incorporating COPRA design software, we are able to manufacture to international standards for our clients.

a. Thickness : 2.5--4mm (±0.2mm) , Width: 750mm±5mm,

b.Yield strength is 235Mpa, side bend less than 10mm( base on 5mm),

c.Coil Inner-diameter:φ508~φ600mm; Coil Inner-diameter: ≤φ1800mm,

d.Coil weight: ≤10T

I.Basic machine parameters

II,Overview of equipment structure

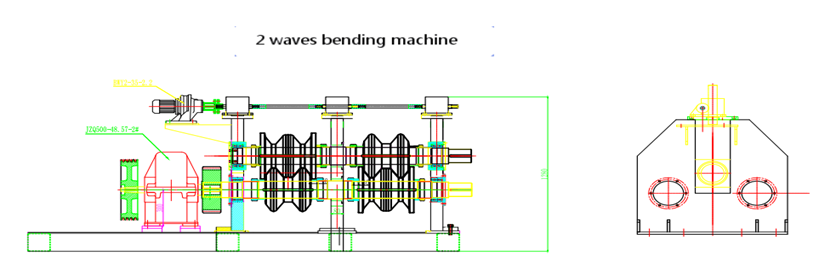

The equipment frame is processed by A3 steel plate, after aging treatment, 3-roller structure, 1 upper and 2 lower, the lower roller adopts a fixed structure, the upper roller adopts slider movement adjustment, and 3 sets of turbine box drive are driven by the motor to adjust the upper and lower The turbine box is connected by a connecting rod to ensure the synchronization of 3 sets of boxes, and the 3 independent wall plates are connected by a shaft to ensure the parallelism of the whole machine. The diameter of the roller shaft is 110mm. There are two sets of molds on the left and right, one for the inner arc and one for the outer arc, and a set of 15KW main motor. It is driven by a ZQ500 reducer, which drives the left and right lower shafts through gears.The gear module is 10m, one for each left and right.The product is processed through the operation console.

III,Equipment configuration checklist

| No | Part Name | Quantity |

| 1 | Forming mould | One set of molds on each side |

| 2 | 15KW drive motor | 1Set |

| 3 | Forming mold shaft | 3Sets |

| 4 | Turbo lift | 3Sets |

| 5 | Lifting drive motor | 1Set |

| 6 | ZQ500 reducer | 1Set |

| 7 | Electrical console | 1Set |

| 8 | Equipment anchor bolt | 1Set |

|