| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Sheet Metal Equipment |

|---|---|

| Place of Origin: | Guangdong, China (Mainland) |

| Brand Name: | Kinte |

| Certification: | Certificate of conformity of quality management system certification |

| Model Number: | customized |

| MOQ: | 1 |

| Price: | Customized |

| Packaging Details: | Customized |

| Delivery Time: | customized |

| Payment Terms: | TT,L/C |

| Supply Ability: | Customized |

| Company Info. |

| Guangzhou Kinte Electric Industrial Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

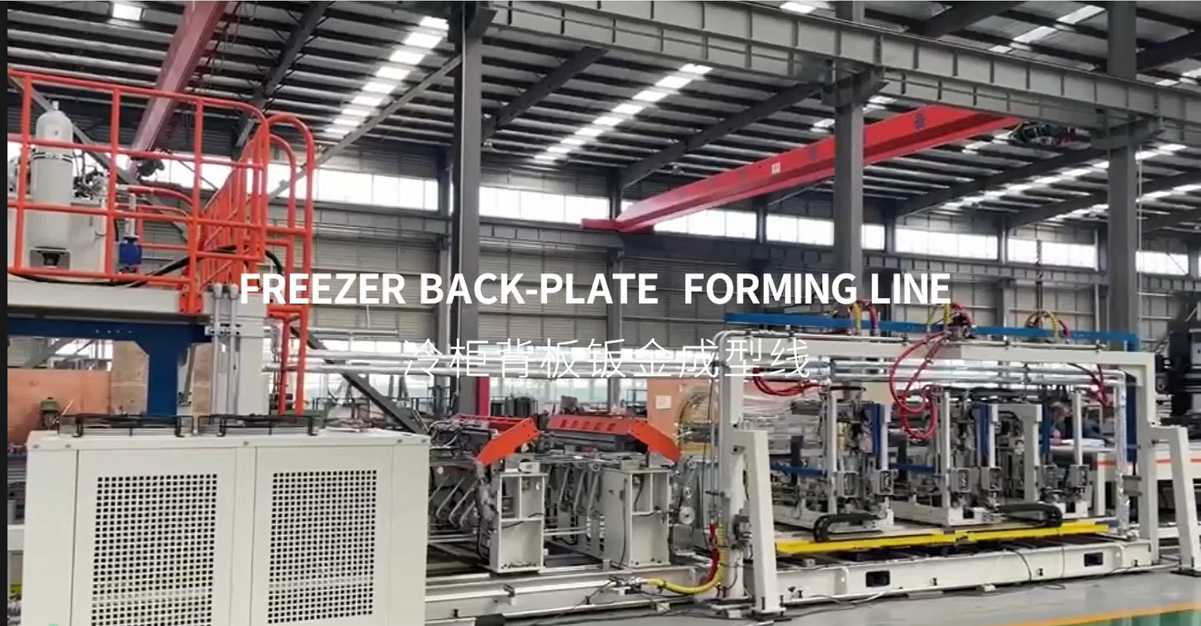

Freezer Back-Plate Forming Line - Precision Metal Forming Solution

The Freezer Back-Plate Forming Line is a fully automated production system designed for high-efficiency manufacturing of refrigeration cabinet back panels. This advanced metal forming line integrates multiple precision processes to transform metal coils into finished back-plates with exceptional accuracy and consistency.

Complete Automated Workflow

The production line features a comprehensive sequence of operations

including:

Automatic material loading for continuous feeding

Progressive blanking for precise sheet metal cutting

180° turning and rotating for dual-side processing

Precision roll forming for consistent profile shaping

Automated cutting to required lengths

Robotic unloading for finished product handling

Key Technical Advantages

Engineered for industrial durability and precision, the system

incorporates servo-controlled mechanisms and PLC automation to

ensure:

±0.5mm dimensional accuracy

15-20 panels per minute production speed

Seamless integration with upstream/downstream equipment

Minimal material waste through optimized nesting

Versatile Production Capabilities

The forming line accommodates various metal materials (GI, PPGI,

aluminum) with thickness ranging from 0.3-1.2mm. Its modular design

allows quick tooling changes for different back-plate

specifications, making it ideal for manufacturers producing

multiple refrigerator models.

Smart Manufacturing Features

Modern IoT-enabled controls provide real-time monitoring of

production parameters, predictive maintenance alerts, and data

collection for quality traceability. The energy-efficient design

reduces power consumption while maintaining high output quality

standards required in refrigeration applications.

This automated forming solution significantly improves production efficiency while reducing labor costs, delivering consistent quality back-plates for freezer and refrigerator cabinet assembly.

|