| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Starch Separator |

|---|---|

| Place of Origin: | China |

| Brand Name: | Peony |

| Certification: | ISO9001 |

| Model Number: | PDSS |

| MOQ: | 1 set |

| Packaging Details: | Standard export packing |

| Delivery Time: | 60-75 days after down payment |

| Payment Terms: | TT,.LC, Western Union |

| Supply Ability: | 100 sets per month |

| Price: | USD17500-22000 FOB SHANGHAI |

| Application: | Starch |

| Operation: | Automatic continous |

| Discharge type: | Nozzle discharge |

| Capacity: | 8-30m3/h |

| MOC: | SS |

| Bearing: | SKF |

| Control panel: | With |

| Product Name: | Starch Separator |

| Company Info. |

| ZHANGJIAGANG CITY PEONY MACHINERY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

High Precision Sieving Stainless Steel Starch Separator For Cassava Corn Wheat

Description:

1.Starch,including wheat starch,corn starch,cassava starch,potato starch

2. Wheat starch needs the disc separators to help the process to separate starch A,starch B and gluten whatever use traditional Martines or 3phase tricanter process..as corn starch as said,it needs disc separator to exact it into the requested Baumé degree,

3.Peony disc separators have various kinds of models to work in such starch separation and extraction stage.

4.Plant starch has been used as a source of raw material for

high-quality starch. Today, consumption of fresh water and energy

play a more important role in starch applications.

Competitive Advantages:

Working Principle

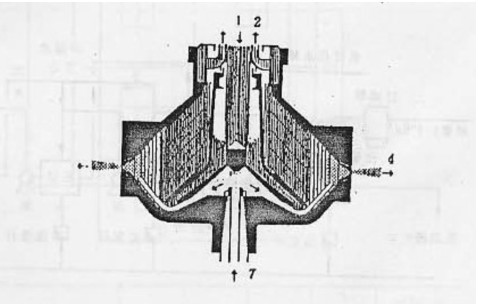

PDSS type separator mainly consists of the feed device, rotating drum, cover, the body, horizontal shaft, vertical shaft, groundwater pump, machine base, motor, and other components.

When the rotating drum running high speed, when the material enter

into the disc separation area through the feeding pump (1), under

the action of the centrifugal force field, the starch particles

slip to the inside wall of the drum, discharged from the nozzle(2),

and the light phase like protein and others will collect to the

drum center, discharged out of the machine via centripetal

pump(3).The machine has a washing bottom pump, the washing water

into the drum from the vertical center hole(4), it is used for

washing the yellow paste of the starch material, and effectively

improve the quality of starch.

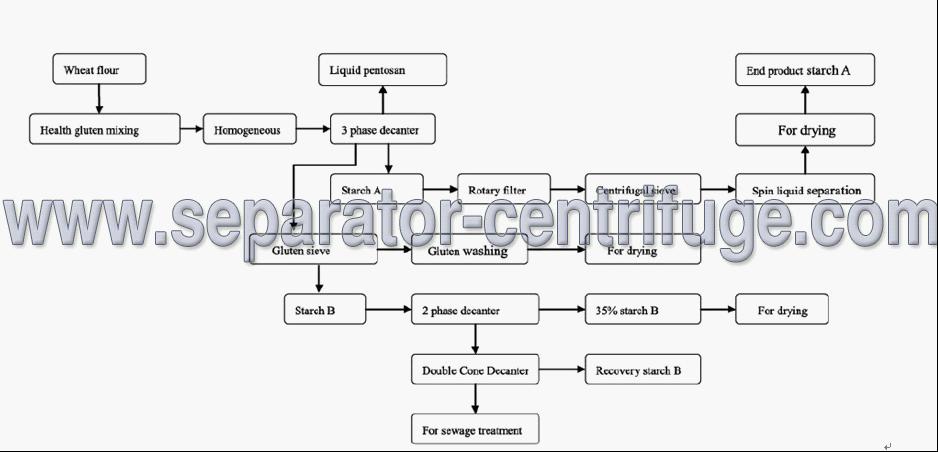

Wheat starch process chart

In the flow chart, the 3 phase decanter is mainly used for separate starch A, B starch gluten, and gluten. At present, this 3 phase decanter is mainly produced by FLOTTWEG/WESTFALIA and other foreign centrifuge manufacturers.

On this wheat starch production line, we can supply the wheat starch "B" concentration and dewatering equipment-Disc separator and decanter centrifuge

Wheat starch“B” waste:1.5-3Be‘

After the nozzle separator treatment, the underflow concentration is 3-10 Be‘

after concentration and dewatering, the solids content is about

45%.

Specification:

Reference picture:

Guarantee:

Peony Centrifuge has been dedicated to producing machinery and

equipment and carrying out facility construction, pursuing the best

quality, and producing the best product at the same time.

We are committed to rewarding you with better quality in return for

our interest in and faith toward.

We will do our utmost for one more stepping forward, based on our

infinite services and trust to customers.

Our service

1. 12 months guarantee period from machine arriving date.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4. 7*24 hours of a technical consultation.

5. Your workers could get trained both in our factory and yours.

6. Routine tracing until the machine works properly will be done timely.

7. We will remind you to do normal maintenance.

8. Your suggestions or any comments & reflection would be treated in priority.

9. The marketing team will visit you during our visit to your country if you require it.

|