| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Drilling Mud Centrifuge |

|---|---|

| Place of Origin: | China |

| Brand Name: | Peony |

| Certification: | ISO9001&ISO14001,CE |

| Model Number: | PDC |

| MOQ: | 1 |

| Packaging Details: | Standard wooden case |

| Delivery Time: | 60-75days |

| Payment Terms: | TT,.LC |

| Supply Ability: | 60sets per month |

| Company Info. |

| ZHANGJIAGANG CITY PEONY MACHINERY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Automatic Continuous Oilfield Drilling Waster Management Decanter Centrifuge / Drilling Fluid

Applications:

Drilling mud is an integral part of most drilling operations,it is also called drilling fluid, there are some solids suspended in the fluid

Peony Decanter Centrifuge can provide solid-liquid separation technology to your drilling mud application, enabling reuse of the material and more efficient and cost-effective disposal.We have our special design and collocation decanter centrifuge for oilfield and industrial solids control, drilling fluid / mud cleaning and process water treatment.

Peony Decanter centrifuges are used to process water-based and oil-based drilling fluids. Oilfield decanter centrifuges mechanically increase the gravitational force exerted on the liquid and solids mixture present in the mud system. We can apply over 3,000 G-forces machine to separate the particles in the fluid

Peony Decanter centrifuges have wide process capacity to meet all ranges as per drilling program.It is commonly and widely used used for oilfield and gas well operations providing efficient solids control while significantly reducing the operator's total mud cost and minimize waste disposal volumes.

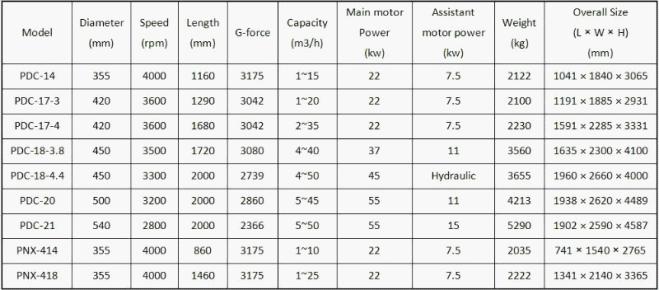

Specifications:

Gravity separation

On account of difference in density, the mixed liquid in the container, after a period of time, is gradually divided into 2 layers. The heavy phase particle of the mixed liquid deposits to the bottom of the container, while the light phase one suspends to the upper surface. A rather distinctive dividing plane forms between the light and heavy phases. The separation speed is affected by the difference in density between the light and heavy phases that make up the mixed liquid. The larger the difference in density is, the faster the separation speed will be.

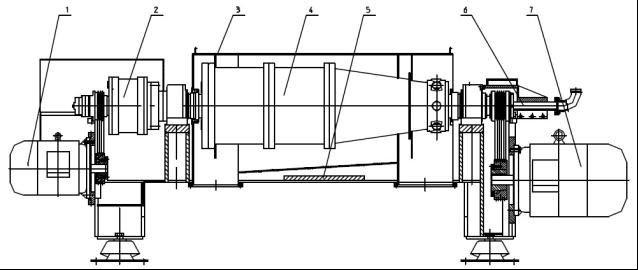

1. Back drive motor 2. Gear box 3. Hood 4 Drum 5 Pedestal 6 Feeding pipe 7. Main motor

Separation principle

Taking advantage of the principle that the light liquid, heavy liquid and solid phase, with different density and mutually insoluble in the mixed liquid, gain different sedimentation speed in the centrifugal force field or gravity force field, separating stratification or causing the solid particles in the liquid to deposit can be achieved.

In the gravity force field or centrifugal force field, the light liquid phase, the heavy liquid phase and the solid phase with different density and mutually insoluble in the mixed liquid, respectively gain different sedimentation speed, and thus separate and stratify. In the gravity force field it is called gravity separation, while in the centrifugal force field it is called centrifugal separation.

Reference Drawing:

|