| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Steel Structure Poultry House |

|---|---|

| Brand Name: | KXD |

| Model Number: | KXD-EQUIPMENT |

| Certification: | ISO9001&CE Certification |

| Place of Origin: | China |

| MOQ: | 200 square meters |

| Price: | 30-80 USD per sqm |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 15000 tons Per Month |

| Delivery Time: | 35-55 days |

| Packaging Details: | Steel Pallet Or In Bulk |

| Material: | Q345 Q235 Steel Structure |

| Roof: | Sandwich Panel, Galvanized Steel Sheet |

| Wall: | Sandwich Panel |

| Door: | Steel Insulation Door |

| Window: | Aluminum |

| Connections: | Bolts Connection |

| Surface Coat: | Galvanized |

| Beam: | H Section Steel |

| Column: | H Section Steel |

| Color: | Customized |

| Dimensions: | Customized |

| Design: | Customized |

| Standard: | ASTM, DIN, GB, JIS |

| After-sale Service: | Onsite Installation, Onsite Inspection, Free spare parts |

| Application: | Chicken Shed, Piggery House, Cattle Shed etc. |

| Name: | Steel Poultry House |

| Company Info. |

| Qingdao KXD Steel Structure Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

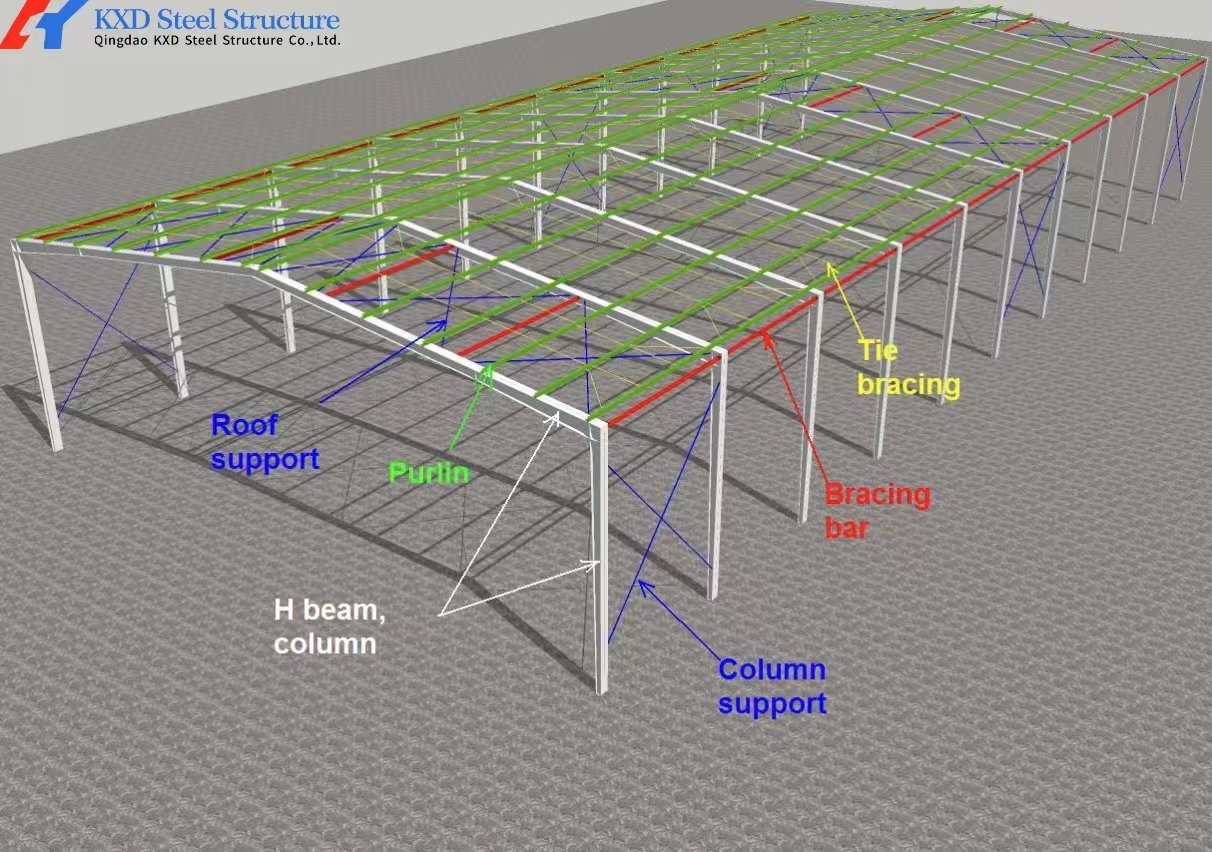

Steel Poultry Shed Specification

Main steel structure | Column | Q235,Q355 Welded H Section Steel |

Beam | Q235,Q355 Welded H Section Steel | |

Secondary Frame | Purlin | Q235 C and Z purlin |

Knee Brace | Q235 Angle Steel | |

Tie Rod | Q235 Circular Steel Pipe | |

Brace | Q235 Round Bar | |

Maintenance System | Roof Panel | EPS/Glass fiber /Rock wool sandwich panel |

Wall Panel | Sandwich panel/ Corrugated Steel sheet | |

Place of Origin | Shandong, China | Certificate |

Accessories | Window | Aluminium alloy window/ PVC window/Sandwich panel window |

Door | Sliding sandwich panel door/Rolling mental door/Personal door |

Broiler Feeding on Ground

| Equipment for Broiler | |

| Main Feed Line System | Silo, Hopper base part , Drive system, Feed Sensor, Feed Drop Part, Main Feed Line,Feed Meter For the Silo etc. |

| Feed Pan system | Hopper, Drive System, Feed Sensor, Delivery System, Feed Pan(Auto Adjustable Gradual), Automatic Line Winch System, Hang Pieces (stainless steel), Anti-roost Accessories |

| Nipple Drinking System | Medicator, Waterline Front Part, Main Water Inlet System, Pressure Regulator, Connecting of Regulator & Re-flush Water Tube, Winch etc. |

| Ventilation | 50''Cone , 36''Cone ,Inlet, Motor for Air Inlets, Inlet Winch etc. |

| Cooling Pad | Cooling Pad with Frame, Cycle Water System, Filter, Water Pump |

| Automatic Tunnel Door for Cool Pad | Panels, Automatic Control Motor, Winch etc. |

| Curtain for Side Wall | Black and Silver Curtain, Manual Winch, Emergency Falling off Device, Lifting System etc. |

| Environment Controller | Climate Controller, Temperature Sensor, Humidity Sensor, Power Box, Control Box, Wires and Accessories etc. |

| Lighting System | Dimming Lighting Controller, LED Energy Saving Bulb, Lighting Control Box, Wire |

| Heating System | Combiterm120e Oil as Fuel etc. |

| Fog System | Drive System, Nozzles of Metal, Stainless Steel, Pipeline System etc. |

| Pressure washer | It could closed by itself when u close the high pressure gun |

| Diesel Generator | DCEC CUMMINS |

Broiler Feeding in Cages

1. A variety of cages to meet the needs of different spans of housing construction

2.The frame structure satisfies the overall stability of the equipment, the mesh wear-stress is changed into a sheet metal wear-stress, which can prevent deformation of the mesh.

3. The main frame of the equipment is formed by one-time forming of 275g hot-dip galvanized sheet, which guarantees the anti-rust ability of the equipment under the premise of meeting the strength of the equipment.

4. The cage door is a fully open structure. When the chicken is caught, the chicken wing breaking rate is reduced, which is convenient for operation.5. Double-layer scraping structure ensures sufficient separation of manure and feces.

6. After the welding of the mesh is completed, it will be hot-dip galvanized, so it is corrosion-resistant and anti-aging, which has a service life of 10-15 years.

Layers Feeding in Cages

• Adopt hot-dip galvanization technology to ensure the service life of 20-25 years.

• H-type cage is the room saver, can reach more breeding quantity.

• Automatic drinking, feeding, manure cleaning and egg collecting can greatly save energy and improve the working efficiency

• Long service life, high stability, and high output rate of return and comprehensive rate.

• High degree of mechanization, high degree of hygiene in the chicken house, low irritating smell, and clean feces disposal in place. H type cage can meet the needs of large-scale farming.

Environmental System

Environment control system has chicken grow temperature curve, minimum air volume curve, light curve, automatic control crosswise and length ways ventilate. Control exhaust fan, heater stove, curtain, cooling pad, light system and feeding line. The system can through the mobile phone to realize remote real-time monitoring and management.

The advanced livestock and poultry environment controller adopts the latest intelligent control technology, which combines temperature, humidity, static pressure, ventilation, lighting and other parameters with the poultry feeding process parameters. It has the characteristics of stable temperature control, adequate and reasonable ventilation, automatic timing lighting, accurate and reliable. The controller adopts large-scale touch screen, which can directly display the operation status of all equipment in the poultry house, and it is easy to operate.

Ventilation System

Includes cooling pad, aluminum frame of cooling pad, cooling water circling system, 52’ high-negative cone fan etc.

1. Buttery gate design of small wind resistance, good performance, reduce the load of the motor.

2.Reasonable air volume, air force.

3.External motor repair, convenient.

4.Frame adopts high quality galvanized steel sheet.

5.Three-phase energy effiicent cient motor.

6. 3G certification, safe and reliable.

Our Service

1. Make suitable design plan and detailed approval drawings of

steel structure building according to the land layout area and

purposes of building by Tekla, PKPM, 3D3S.

2. Steel structure buildings consultation service.

3. Budget always on deck for our client

4. Meticulous Fabrication,with great precision.

5. Erection & installation of steel structure building. Our

technician and skilled workers can be dispatched on site to guide

or erection process.

6. Transportation & delivery per your requirements

Package & Loading

Product Packaging:

All components are packed in bundles and secured with steel straps.

The main frame is packed in a container or shipped as a single package.

Wall and roof panels are packed separately to avoid damage during shipping.

All necessary fittings and accessories are included in the package.

Shipping:

The Steel Structure Poultry House will be shipped by sea.

Delivery time will vary based on the destination and shipping method.

Customers will be provided with tracking information once the product has shipped.

Our Team

Our commitment to customer satisfaction means that we are always available to answer any questions or concerns that may arise, and we work tirelessly to ensure that our customers are fully satisfied with their purchase. We are dedicated to providing top-notch technical support and services for the Steel Structure Poultry House product.

|